Using a tabletop jigsaw you can make furniture, beautiful patterned shelves and much more at home. The mechanism allows you to cut smooth and curved parts from wood, plastic and dense foam materials. In order for a homemade device to fully satisfy the requirements, it is necessary to carefully select a suitable design.

Design and technical characteristics

The device of any model of jigsaw machine necessarily contains:

- saw;

- crank assembly;

- drive unit;

- saw tension device;

- Desktop;

- auxiliary mechanisms.

The material to be processed is placed on the work table. Some models are equipped with a rotating device that changes the inclination of the surface. To make it easier to mark the material with your own hands, graduations are applied to the surface.

How larger size table, the longer the cut can be made. On average, this figure is 30 - 40 cm.

Drive power for homemade desktop machine is about 150 W.

The crank assembly converts the rotational motion of the drive into reciprocating motion and transmits it to the saw. On average, the frequency of saw blade vibrations per minute is 800 - 1000. The amplitude of vertical movement is no more than 5 cm. Some models allow you to select the speed of movement depending on the properties of the material.

The file of a manual jigsaw can work with wood and plastic with a thickness of no more than 10 cm, having a length of up to 35 cm. For different types of materials and work, the files vary, their width is 2 - 10 mm.

A manual tension device secures the saw blade for uniform sawing; it consists of screw or leaf springs.

Types of machines

Structurally, all jigsaw devices can be divided:

- with lower support;

- with double support;

- on suspension;

- with degree scale and stops;

- universal.

The most common are models with a lower support. Their frame is divided into two halves: lower and upper. The cutting and cleaning module is located at the top. At the bottom there is a control module, an electric motor, a transmission mechanism and a switch. Allows you to process sheets of material of any size.

Models with double support differ in that there is an additional rail on the upper half of the bed. Such devices are good for creating oversized parts. They are easier to install than the previous option. Both models allow you to process material no thicker than 8 cm. The machine comes with a work table with angle and height adjustment.

Suspended machines are not equipped with a monolithic frame; they are very mobile. During processing, it is the cutting module that moves, not the material. The working module is usually attached to the ceiling with your own hands, so the size of the material is unlimited. Cutting tool moves by hand independently of the bed, creating very complex patterns.

Machines with a degree scale and stops are good for precise work according to drawings. The design allows you to avoid errors. Universal jigsaw machines can perform several operations associated with cutting: drilling, polishing, grinding.

Making a machine yourself

Homemade drawing table jigsaw: 1 — rocking insert (2 pcs.), 2 — earring (2 pcs.), 3 — table, 4.6 — screws, 5 — rod, 7 — eccentric, 8 — base, 9 — earring axles, 10 — upper rocker arm , 11 — rocker axis, 12 — wing, 13 — cross member of the tension screw (2 pcs), 14 — tension screw, 15 — rocker stand, 16 — lower rocker arm, 17 — box, 18 — double-ribbed pulley, 19 — intermediate shaft, 20 — stand bushing, 21 — table plate, 22 — bearing with cover (2 pcs.), 23 — electric motor pulley.

In the drawing of a tabletop machine made by yourself, the number of components must be kept to a minimum, these are: a rocking chair with a fixed saw, a bed and an electric motor. You can take a motor from an old electric machine.

Owners of a manual jigsaw are luckier. You can make a stand from a sheet of plywood and attach a jigsaw to it. To attach the jigsaw with your own hands, you will have to make holes in the base of the tool. The most simple model ready.

Now about the more complex and functional ones. The stand is made by hand from 12 mm plywood, thick plastic or textolite. It consists of a base, a box for housing the engine and mechanisms, and a work table. On the other side we place a rocking chair with an eccentric. They are connected to each other by a metal plate with bushing bearings. The entire structure is secured with screws. To mount the intermediate shaft, prepare a pair of bearings. The double-strand metal pulley is fitted onto the shaft as tightly as possible, screw connection is fixed. You can make an eccentric in the same way.

To change the amplitude of movement of the rocker, four round through holes with threads are made on the eccentric flange, located at a distance from the axis by different distance. By changing the installation location of the screw, the range of movement of the rocking chair is adjusted. It consists of a pair of wooden rocker arms hinged to a stand. The rear ends of the rocker arms contain through cuts; tension screws are inserted into them. A file is attached to the ends at the front and is movable due to metal hinges. Before fastening, the file is inserted into the groove of the working surface of the table.

The mechanism for attaching the file is very important. During production homemade device with his own hands he should be given Special attention. The rocker arm insert plates carry permanent loads when moving, therefore they are rigidly fixed and tightened with Grover screws and washers. The fastening earrings should not be strongly compressed by the screws, allowing the hinge axis of the plate to move.

I didn’t want to permanently place my expensive Makita jigsaw on the table, so I decided to buy another one to create a table. I was very lucky to find a jigsaw in the “Our House” store Caliber LEM-610E for only 862r. Includes: wood saw, side stop, adapter for vacuum cleaner, spare brushes for the motor.

There was an outlet next to the display case and I looked at it in action. It is quite well made, convenient, there is a speed control with a wheel, and the activation is fixed with a button. The saw holder moves smoothly without any play.

It’s very fortunate that I was able to twirl it in my hands before buying it; I wouldn’t risk ordering it from the Vseistrumenty.ru website without knowing what it is. (Although they write good reviews about it) By the way, it costs more there and there is also a delivery fee... so I successfully bought it at Our House. :)

Despite its advantages, it has a number of disadvantages that I noticed upon closer examination:

1) The file does not fit into the saw holder. Apparently this is a defective copy, but I did not waste my time on the exchange. Each file has to be sharpened. (Although I won’t be able to use them on the second jigsaw after grinding - it doesn’t matter, they are relatively inexpensive)

2) And this flaw is visible even in the picture. The canvas is tilted strongly forward. (This was also corrected by placing tin strips under the back of the sole, achieving 90 o.

3) The speed control wheel turns heavily, not very clearly and with jamming. At the minimum speed value, the tool cannot start at all (However, the same garbage with the start is also true for my other “calibrated” drills. This is unpleasant, but does not spoil life much)

As always, everything is in the spirit of minimalism. I did not make a separate switch. It is quite convenient to turn on with a standard button and lock into place.

To do this, I bought a bracket at KrepMarket (this is a fastening element from some kind of iron structure system)

By the way, I really love CrepeMarket. Any screws, nuts, screws, fasteners. Every time I design something, I wander around in thought and collect the necessary details.

I cut off the excess and sharpened it.

Back view. Now the distance between the bearings has a fixed clearance for the file of 1.2mm. I have a plan for the future: to make a gap adjustment.

For thin materials it can be lowered.

As an experiment, I drew a star and tried to cut it out evenly

For a 130mm file, the maximum possible thickness is 5cm. It turns out there are very long files; I recently saw a 300mm file on the market

I sawed off a 1.5mm slice from a 40x40mm block

Which is what I did. Now you can use it to cut long workpieces 11.5 cm wide. The old L-shaped structure also remains, and if greater strength of the holder is needed, it can be installed again, although new design remained quite strong and reliable.

I also came up with the idea of making a knife from an old dull file, grinding off its teeth and sharpening it.

They can be used to cut material like sealant into shapes. The cut is smooth. Much better than a utility knife. The photo shows a mouse pad.

Well, that's probably all. The table turned out to be reliable and comfortable. Now I have a tool with which I can perform more delicate work than with a circular saw.

Lately I have been very interested in cutting out with a jigsaw, I don’t even know why. It all started with the fact that I needed to cut out several gears from plywood...

And off we go. At first I cut out the gears by hand, then I thought, pumping the muscle with a hand jigsaw is of course good, but if you automate the process, it will be much faster!

So, first of all, let’s get acquainted with this manual jigsaw for artistic cutting.

(all photos in this article were found on the Internet)

To saw you need files, they are thin as wire, with sharp teeth. Previously, such files were sold in a pack of 50 pieces, recently I went to the store, and these “bimesmen” started selling them individually. You can break a couple of these files in an evening.

For cutting, we will also need a special table, it can be a board with a conical slot, screwed to the table with screws or a clamp.

To make it easier to attach saw blades to the machine, it is better to use special device, which will compress the contour of the jigsaw, so you can easily change the file without effort. With the help of a wooden eccentric, compression occurs.

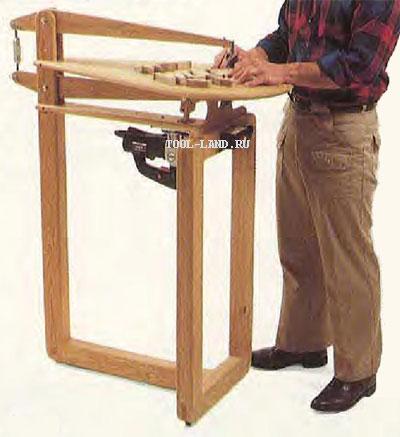

And now about automation. On next photo you see table jigsaw factory type, you can find a sea of different modifications on the Internet. This thing is not very expensive, but even if I really want it, I won’t be able to find it in my city, and in principle there’s no need.

Industrial machines are, of course, good, but I’ll probably use them for a couple of months and give up on this activity, and in general, such a machine, as I learned, can be easily assembled yourself from plywood and wooden blocks.

The following photo uses industrial manual jigsaw and a spring for returning the saw.

So, we can easily assemble a tabletop jigsaw with our own hands at home. I personally did just that, but I have a special design, there are no photos of me in this article, but I will definitely post them, as well as a video in progress.

Homemade jigsaw.. Sounds unreal. However, professionals have always been valued and in demand. Carpentry can be both your main income and a pleasant hobby. The hands of a carpenter produce wonderful products, unique and inimitable. IN modern world, with its terrible ecology, every person increasingly strives to surround himself with natural, natural materials. Handmade wooden items can become an exclusive, priceless gift.

A jigsaw is capable of cutting any sheet material lengthwise and crosswise.

But in order to create all this magic, you will need not only quality wood, but also tools. A wide variety of wood jigsaws are sold in stores, but a true master will not be satisfied with such a tool. Because they are not suitable for performing truly delicate jewelry work. There is only one way out - to make a jigsaw. If you have hands and a bright head on your shoulders, then you can do this task.

There are several options for manufacturing such a tool: upgrade purchased model or make it from available materials. There are two types of jigsaws for wood: manual and electric. Hand tool– this is a classic.

Making from a sewing machine

Necessary materials:

- old-style sewing machine;

- file

Sequencing:

- After unscrewing the bolts, the needle is carefully removed.

- The drive shaft is removed.

- The protective panel is unscrewed.

- The hole for the needle expands to the size of the prepared file.

- The length of the file is trimmed to the size of the needle.

- The top and bottom of the file are ground off.

- The file is inserted in place of the needle.

Materials for tabletop jigsaw:

- duralumin pipe;

- copper sheet;

- plastic;

- drill;

- clamps

Sequencing:

- You need to make a frame from a duralumin pipe.

- When making it, do not forget about the need for a channel in order to subsequently lay the power cord.

- Making a C-shaped frame from a copper sheet. Next, it is attached with screws to the frame in the place where it connects to the handle of the tool.

- A gap is cut in the plastic. A file passes through it. You will need a drill to cut the hole.

- Mounting holes are drilled on the plastic.

- The jigsaw is attached to a plastic base so that the file passes through the gap.

- The structure is attached to the table using clamps.

Return to contents

The jigsaw consists of a motor and a rocker with a saw.

Motors from washing and washing machines can be used for the motor. sewing machine. The body is made of plywood. It includes the base itself and the table. The box should be located between the base and the table, and on inside shelf-bracket and intermediate shaft. And on the reverse side there is a disk and a rocking chair.

The eccentric is connected to the rocker using a rod. The rod is made of steel plate. It's all connected with screws. The intermediate shaft should be installed on several bearings; they are covered with a lid to prevent dirt and sawdust from entering. The double-strand pulley is placed on the shaft and secured with screws. The eccentric of the jigsaw is also installed. Four holes are drilled on the eccentric flange. Thanks to this, the stepped screw will change position. Accordingly, the amplitude of the swing will change. A rocker is a wooden rocker in which you need to install a screw. And on the front side of the structure there are metal plates with hinges, with the help of which the files are attached. The file is placed in the slot of the work table and clamped tightly.

Rocker arms oscillate frequently and violently during operation, and the plates are subjected to excessive heavy loads. Therefore, it is necessary to pay due attention to the correct fastening of the saw. The plates must be securely fastened in the slots and tightened firmly. But the earrings that hold the files are installed in such a way that the screws do not clamp the halves too tightly.

The axis should get a little freedom. The screw that tightens the rocker arm must have a small gap for the thrust screw. The rocking stand itself can be made from a block. A groove is made on the upper side of the block for the upper rocker arm. The stand can be made from halves or made into composite parts.

These are the homemade items you can make with your own hands. There are different jigsaws for wood, but better than that that you make with your own hands cannot be found. Such a tool will serve you faithfully for many years. This is a real help for home handyman. There is so much you can do using this simple unit. But still, this device can be dangerous, so before you start working, you should familiarize yourself with the rules for using the tool.

A tabletop jigsaw machine will be useful to every craftsman who cuts out thin parts. However, it is not always possible and meaningful to purchase a full-fledged machine. In that case, get down to business and make it yourself!

The structure of a jigsaw machine - what lies inside?

Jigsaw machines are more related to special tools than to devices that are needed as to an experienced master, and for the amateur who manages the garage. Their purpose comes down to a special task, namely cutting out complex curved contours from sheet materials. A special feature of such machines is the execution of cuts without violating the integrity of the external contour. Most often, sawing occurs on wooden and derivative materials (plywood, chipboard, fiberboard), although modern machines equipped with appropriate saws can also work with other materials, for example, plastic or plasterboard.

Such equipment has found application in the music industry (manufacturing musical instruments) and, of course, in the furniture room. Those who like to make things in their own workshop also buy such units. The structure of a traditional jigsaw machine, designed according to all the rules, looks like this: the working surface on which the saw is mounted hides a drive (electric motor) and a crank structure underneath. The tension mechanism can be located either below or above the machine.

To process a part, it must be placed on the workbench. Many models have the ability to rotate it under different angles to make bevel cuts. The stops and guides on the surface, as well as the rotating mechanism, can be marked, which greatly simplifies and speeds up the work. The length of the cut depends on the length of the work table - most models are limited to 30-40 cm. Electric motor power is an important, but still far from the most fundamental factor, since the machine has a huge reserve of unclaimed power. For example, for a home workshop or even small production, an “engine” of only 150 W is sufficient.

The crank mechanism is much more important detail, because in this case, the quality of transmission of the drive’s torque into the translational-reciprocal motion, directed in the vertical plane by means of a saw, depends on it.

Standard jigsaw machines are considered to be devices with an amplitude of movement of around 3-5 cm and a vibration frequency of up to 1000 per minute. Many models provide a change of speed mode for different materials. The jigsaw file itself is usually made up to 35 cm long and is capable of sawing material up to 10 cm thick. The width of the files can vary in a fairly wide range - from very thin two-millimeter to coarser ten-millimeter, with a thickness from 0.6 mm to 1.25 mm.

Even the thickest and widest file will easily break if you do not provide sufficient tension along the entire length of the file. Leaf and coil springs are used for this. Quite often, such machines are equipped with an air pump, which cleans the cut from sawdust by blowing it, as well as a drilling unit. The latter device is especially useful, because in this case the master does not need to be distracted by connecting an electric drill and drilling a hole - everything happens on the working plane of the machine. Of course, you have to pay for convenience!

How to make a jigsaw with your own hands from a manual jigsaw?

On the Internet you will find many different designs homemade machines, but most of them come down to repurposing into this device. By using your ingenuity and watching the video, you can easily make a homemade jigsaw from this tool. The jigsaw only needs a little modification. In fact, it plays the role of a machine drive and a crank mechanism, but the rest needs to be thought out and implemented.

Of course, manufacturers are trying to please consumers in this area as well, offering their own platform options for quick and convenient remodeling, however, in reality only you can make a device that suits your needs. So, the first step is to make a support table, for which they most often use sheet metal. You need to make a beveled oblong hole in it for the saw blade and holes for fasteners (countersunk screws are recommended), and attach the jigsaw to the bottom of the support table.

This structure can only be strengthened wooden table. You can go beyond this and install guide rails. The convenience of such a device lies in the fact that in addition to performing functions that are not entirely inherent to it, you can always disconnect the drive and with a slight movement of your hand turn it back into a manual jigsaw! If you constantly need this tool for work, it makes sense specifically for the machine - it will be cheaper than spending money on a real machine.

Advantages and disadvantages - we continue to modify!

But such a unit inherits not only the advantages of the tool, but also its disadvantages, in particular, the file is too wide for filigree work, which significantly limits the curvature of the lines. If there is a need for this, there will be a way out. So far, our machine differs from the classic jigsaw unit in the absence of springs that would ensure sufficient tension on the file. But it’s quite easy to build a simple rocker, which on one side will be under the tension of springs, and on the other, fixed to a nail file.

There is another option - to clamp the nail file between two guide rollers, but the first option is still more reliable. Be sure to turn off the pendulum action on your jigsaw before using it. homemade machine. There is another design - if your tool is powerful enough, then it can only serve as a drive in a structure of two rocker arms, between which a nail file is stretched. The movement is transmitted through a file attached to the lower rocker.

Machine from a sewing machine - giving a second life to old tools!

If you inherited a foot or hand weapon from your grandmother or mother sewing machine, consider yourself the owner of an excellent jigsaw! Of course, for this you need to “work a little magic” on the machine. First, remove the thread weaving device, which is usually located at the bottom of the machine. There is nothing complicated about it, just unscrew two bolts. Then we knock out the cotter pin and remove the drive shaft leading to the thread weaving mechanism.

Having unscrewed the top panel that protects the mechanisms, it is necessary to expand the slot in which the needle went. Be guided by the needs and width of the nail file that you will use in your work. Files for a jigsaw of this kind also need to be slightly modified, namely cut to maximum length needles that could be used on this machine. Grinding off the upper teeth and sharpening bottom part on the tip, all you have to do is insert the file into the needle holder and test your machine in action!