Most of the surviving monuments of wooden architecture were built without single nail, with the help of only one ax, and this fact still causes admiration. But over the centuries, fastening systems made of metal and used for construction have changed greatly, so today there is no point in repeating the “feats” of our ancestors. It must be built simply, quickly and reliably. Let's look at the metal fasteners offered by manufacturers using the example of components and elements that can significantly simplify and speed up the connection of floor joists with beams or, and at the same time some other operations.

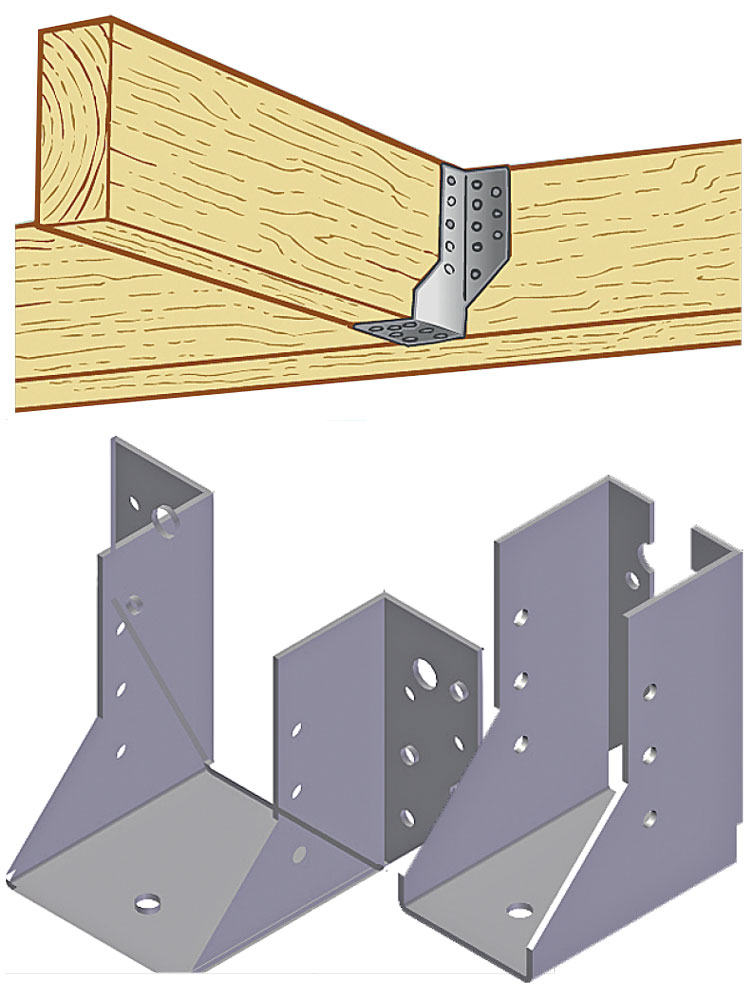

Photo: ESSVE. The beam shoes are equipped with 5 mm diameter holes (located on both the flange and the flanges) for nails/screws and 9 or 11 mm diameter holes for bolts or cap screws. On the lower surface of the flange there is a hole with a diameter of 7 mm for additional fastening of the log

1. Connecting elements with perforation

Photo: Eurotec. Special elements for performing common tasks wooden house construction operations: adjusting screw for window frames or sheathing (a); tightening screw (b); Hobotec self-tapping screw for fastening solid boards, blockhouses or imitation timber for cladding wooden house(V)

If beams and floor joists are invisible in the interior, then they can be connected using so-called beam shoes, produced, for example, by Essve. These elements are suitable for fastening wood not only to wood, but also to concrete or brickwork(when using the appropriate ones). They are made mainly from hot-dip galvanized steel with a thickness of 1.5 or 2 mm, but there are also more expensive products on the market made from stainless acid-resistant A4 steel. The shoes are available in two versions: with cuffs turned outward or inward. Price: from 50 to 500 rubles. for 1 piece

The manufacturer recommends fastening the beam shoes to the elements being connected with special anchor screws with a diameter of 5 mm (depending on the load, the latter can be inserted into all or some of the holes), and in case of a very heavy load or fixation to “stone” material, also use the holes for bolts. In addition to anchor shoes, the market offers perforated universal clamps(A), rafter fastenings(b), angles (c), plates (d) shown in the figure, etc.

Advantages of anchor screws

Why do manufacturers of perforated fasteners suggest using anchor screws? How are the latter better than ordinary self-tapping screws or anchor (ruffed) nails used to secure beam shoes and other perforated metal elements?

The advantages are due to the design features of anchor screws.

Firstly, their flat head presses the metal element being fixed more tightly to the wood.

Secondly, the smooth cylindrical part located under the screw head has the same diameter of 5 mm as the holes in the perforated metal elements. It completely fills the hole and therefore completely transfers the load, and also works well for shearing. In addition, thanks to the tapered head, the screw is better centered.

An ordinary self-tapping screw does not always transfer the load completely; it performs much worse at shearing. Well, the anchor nail cannot be dismantled without destroying the part of the wooden element into which it is driven.

But the anchor screw is easily unscrewed and can be screwed into a wooden element in a new place.

2. Metal tongue-and-groove systems

The Atlas node connector is produced by the German company EuroTec. The element is made of aluminum and consists of two parts, one of which is equipped with a tenon, the second with a corresponding groove. They are fastened to each other according to the principle “ dovetail", which allows for reliable transmission of vertical and horizontal forces, to absorb tensile and compressive forces and even bending moments. The connection can be either visible or hidden, for which both metal parts are recessed into pre-milled grooves. The length of the Atlas node connector is 70–200 mm. Price - 1500–5500 rub. for 1 piece

EuroTec's main competitors on the Russian market are the Austrian companies PITZL and SHERPA Connection Systems, which produce a similar range of connecting elements. The SHERPA system is better known, providing a load-bearing capacity of connections from 5 to 280 kN -

special program for calculations allows you to select fasteners for each specific case. Any connector consists of two aluminum parts, which are also fastened using the dovetail principle. The cost of SHERPA elements is from 800 to 12 thousand rubles. for 1 piece

Photo: VV Stanz-und Umformtechnik, PITZL. SHERPA connectors (a - e), made of heavy-duty aluminum alloy, and steel elements Explosive explosives (f - h) make it possible to create not only high-strength and reliable building construction, but also very aesthetic stairs and even furniture

Another EuroTec competitor - German company BB Stanz-und Umformtechnik, which developed the BB connecting unit. It is made of galvanized sheet steel 4 mm thick and consists, like its aluminum counterparts, of two parts, fixed to each other according to the dovetail principle. Both halves are attached to the wood with self-tapping screws, the number of which depends on the size of the element. BB connectors are available in 70mm widths and 90, 125, 150 and 190mm lengths. The price is one of the most affordable today: 180–800 rubles. for 1 piece

Connectors allow you to solve problems in a few minutes that would take hours or even days to complete using classical construction technologies.

3. Three-dimensional slats

Photo: Rotho Blaas. Three-dimensional perforated aluminum slats for creating hidden connections: Alumaxi (a), Alumini (b) and Alumidi (c)

The Italian company Rotho Blaas offers to connect parts located both perpendicular to each other in the same plane and at an angle vertically, using T-shaped slats, which are made by extrusion from high-strength aluminum alloy EN AW-6005A. They are available in three modifications, designed for different levels loads: Alumini, Alumidi and Alumaxi. Each contains slats with holes in the base and the shelf perpendicular to it, and without holes in the shelf. The slats can have a fixed length (from 80 to 768 mm), and in versions without holes, slats with a length of 2176 mm are available with cuts every 64 mm, which allows you to produce fasteners of any length.

During installation, the base of the batten is attached to the beam with self-tapping screws, then a groove is made at the end of the log attached to the beam, the dimensions of which correspond to the flange of the batten. If the latter has perforations, then, using the shelf as a jig, holes are drilled in the joist, put it on the shelf and metal pins are inserted into them. If there is no perforation, then put a log on the shelf and fix the connection with self-tapping screws and a drill. Price of rack fasteners: RUB 1,230–18,425. for 1 piece

The connecting system should be selected in accordance with the cross-sectional dimensions of the beams being connected, as well as the static and dynamic loads acting on them.

4. Hidden elements of the “Hedgehog” type

Photo: Rotho Blaas. Installation of the Hedgehog elements is simple. At the end of the log, a recess is made into which the connecting element is inserted and secured with self-tapping screws twisted at an angle. Next, the log through a pre-drilled hole is attached to the beam with a threaded element screwed into the central hole of the connector

Rotho Blaas Disc connectors are a galvanized carbon steel washer. At the base of the washer there are holes drilled at an angle for self-tapping screws, and in the central part there is a threaded hole. A pin is screwed into the latter, its free end is threaded into a hole pre-drilled in the beam and fixed with opposite side beams with a nut with a wide washer placed under it. The resulting connection successfully works both in shear and pull-out. With a heavy load, up to three Disx elements with a washer base diameter of 50, 80 and 120 mm can be simultaneously installed at the end of the joist (diameter threaded holes- M12, M16 and M20 respectively). Price: from 4145 to 9044 rubles. for 1 piece (screws included).

An alternative to Disc connectors are EuroTec's IdeeFix elements. The fastener is made in the form of a hollow cylinder with an outer diameter of 30, 40 or 50 mm, made of aluminum alloy. At the bottom of the cylinder there is a hole with an M12, M16 or M20 thread. In the top there is a conical recess with holes for self-tapping screws, drilled at an angle of 45°. The IdeeFix element is attached in almost the same way as the previous connector, but the joist is fixed to the beam not with a stud, but with a powerful bolt with a wide head (included in the kit along with self-tapping screws). Price - 1500–4500 rub. for 1 piece

5. KonstruX full thread self-tapping screws

These unusual products allow you to save not only the time required to assemble the unit, but also money, because connecting metal elements are not needed. Self-tapping screws have a full thread, creating a high resistance to pulling out, and are completely screwed into the wood at an angle of 30, 45 or 60°, which radically changes the usual pattern of their operation. In this case, the screws only work to pull out, which allows them to take on a significant part of the forces acting on the connection. Thus, it is possible to connect parts at an angle (a), unite elements while reducing their deflection (b), and strengthen cutouts in beams and joists (c) (see figure below).

Photo: Eurotec. Select the appropriate KonstruX screw, the fastening scheme of the elements, and also calculate required amount screws is helped by a special ECS program, which can be freely downloaded on the website of a screw manufacturer or a large retailer

There are self-tapping screws with a cylindrical (screw diameter - 6.5, 8 and 10 mm) and countersunk (screw diameter - 8 or 11.3 mm) head. Length - 65–1000 mm. Price - 20–800 rub. for 1 piece To install screws less than 245 mm in length, no pre-drilling is required, but for longer ones (to prevent slipping to the side), it is recommended to pre-drill holes for the self-tapping screw to a depth of up to ⅓ of its length.

6. Special screws

Using a Hobotec self-tapping screw, massive boards, blockhouses or imitation timber are fastened. The head of the product is equipped with milling ribs and is easily recessed into the wood, and the tip is made in the form of a drill. A cutter in the middle of the length of the screw increases the diameter of the hole, allowing you to tighten the element being fastened more tightly. Self-tapping screws with a diameter of 3.2 mm and a length of 20 to 60 mm are made of ordinary coated steel (price - 1100–2200 rubles per pack of 500 pcs.) or of stainless steel(price - 3500–7500 rubles per pack of 500 pcs.).

The tension screw is also equipped with a cutter, but its tip is different - it has a special groove that turns the screw into a wood drill. The flat cap has large diameter and is equipped with a self-countersinking head and a hexagonal slot. The self-tapping screw is coated with a special wax coating that reduces friction when screwing in. Product diameter - 3–12 mm, length - 30–600 mm. Price - from 300 to 5 thousand rubles. per pack of 500 pcs.

Photo: Eurotec. Self-tapping screw for fastening wood paneling to the steel base. Equipped with a drill tip and special “wings” (located above the tip), which expand the hole in the wood and break when drilling metal. As a result, having cut a thread in the metal, the self-tapping screw is fixed in it, and the head attracts the wooden element to the metal. Length: 32–125 mm. Price: from 500 to 2500 rubles. per pack of 500 pcs.

The adjusting screw is useful, for example, for fastening window and door frames or wooden sheathing to wood, concrete, brick or metal (the element can be equipped with two types of drill bits). The self-tapping screw is screwed into the box and the wall or power element located behind it in one step. In this case, the ring conical “spikes” located under the screw head are firmly fixed in the box (almost like fishing hook), due to which its position relative to the wall is easily adjusted by further screwing or unscrewing the fastening element. Length - from 60 to 125 mm. Price - from 2000 to 3500 rubles. per pack of 500 pcs.

Special self-tapping screws can significantly speed up and facilitate the execution of those operations that are necessary when creating wooden structures.

For use various connections Wood in the field of construction cannot be done not only without tools, but also without relevant experience. That is why inexperienced craftsmen do not always make such connections accurately. One of best options— professionals use various types of fasteners for the array, which are made of metal.

Many surviving architectural monuments made of wood were built without nails, using only an ax. This fact causes true pleasure to this day. However, centuries later, the fasteners made of metal, used to build solid wood buildings, have changed radically, and it is for this reason that today it makes no sense to repeat the experience of our ancestors.

It is preferable to build quickly and without difficulties. Let's talk in more detail about the fasteners offered by manufacturers, taking as an example details that make it possible to simplify as much as possible the connection of beams with floor joists or solid wall surfaces.

Perforated fasteners

When beams, as well as floor surface logs, are hidden in the interior space, they can be connected using beam shoes. This fastener for wood structures is suitable for fastening solid wood not just to wood, but also to concrete and brickwork. It is created from durable steel.

Manufacturers advise fastening such fasteners to the parts being connected with special screws, and in case of excessive load, or fixing to a stone material, use the holes for the necessary bolts. In addition to anchor shoes, today you can purchase special clamps and much more.

Tenon and groove

This galvanized wood fastener consists of a tongue and groove section that fit together to provide better transfer of horizontal as well as vertical forces.

The connection can be visible or hidden; for these purposes, the steel parts are recessed into special grooves in advance.

Three-dimensional slats

The modern Italian company produces fastening elements that are placed perpendicularly and vertically at an angle, using T-type slats created by extrusion from a high-strength steel alloy. They are produced in several modifications designed for different levels of loads.

The fastening system must be selected according to the size range of sections of the combined beams and the dynamic as well as static loads acting on them.

During the installation process, the slatted base is attached to the beam using self-tapping screws. Then a groove of the same size as the slatted shelf is created on the end part, attached to the base of the joist beam. If there is no perforation, the shelf is equipped with a log and the connection is secured using self-tapping screws.

Hidden details Hedgehog

These connectors are steel washers, the base of which is equipped with holes drilled under the slope. These holes are for self-tapping screws. In the center of the washer there is a threaded hole into which a pin is inserted. Its free end is threaded into a special hole and secured on the back side of the beam with a piece with an enclosed washer.

The created connection functions perfectly not only in pull-out, but also in shear. If there is excessive load in the area of the end part of the joist, it is possible to install several elements at the same time.

Fasteners with complex threads

Unusual self-tapping screws that make it possible to save time, cash, since this option does not require metal parts. Self-tapping screws are equipped with threads that help create high degree resistance when pulled out, and are also tightly twisted into an array, which completely changes their traditional functioning.

In this case, the work of the screws occurs exclusively by pulling out, which gives them the opportunity to absorb most of the forces that fall on the connection. So, you can fasten elements at an angle, combine parts, minimizing their deflection, as in the photo of wood fasteners below.

Special purpose self-tapping screws

Using similar elements, quite massive wooden crafts. The cap has milled ribs and is easily recessed into the product, while the tip is created like a drill. In the middle of the screw the cutter makes bigger hole, helping to pull the element as tightly as possible.

An adjusting type self-tapping screw will be useful for fastening door frames, window openings, solid wood lathing to wood, metal. The self-tapping screw is screwed directly into the box, as well as the wall surface located behind it, or the power part.

The self-tapping screw acts as a weather vane for high-quality fastening of solid wood cladding to a base made of steel. It has a tip in the form of a drill and wings placed above it to expand the hole in the tree.

When drilling metal products, the wings break. As a result, having made a thread in a metal part, the self-tapping screw fits tightly to it, while the solid element is attracted by its head to the metal.

Photos of wooden fasteners

The construction of houses made of wood is becoming increasingly popular and in demand. Buildings made of logs and beams are easily and quickly erected. But in addition to the main material - wood, for the construction of a log house it is also necessary to purchase additional elements, which will ensure high-quality fastening of its crowns. After all, just installed on top of each other wooden materials over time, under mechanical stress they will simply fall apart. Fasteners for wooden houses There are a variety of them and at different prices. Therefore, finding the necessary fasteners among a large assortment of these materials is not easy.

Fasteners and why they are needed

Using fasteners, logs or beams are firmly fixed to each other. The walls are the smoothest and most durable. They do not deform, the wooden material itself does not twist, as a result of which large and dangerous cracks do not form in logs or beams. Despite the strong fixation of the crowns, the fastening elements do not interfere with the inevitable shrinkage process, but, on the contrary, help the log house to move through it more evenly and without unpleasant consequences.

To build a wooden house, it is advisable to purchase the following set of fastening elements, which consists of dowels, screw jacks, sliding supports, and “Strength” spring units.

This is a mandatory fastening element, which cannot be avoided when building a wooden house. They are a so-called twig various diameters and size, made of wood or metal. It is not advisable to use metal dowels in the construction of wooden houses. Even if they were pre-treated with powerful compounds while inside a wooden material, they will still succumb to corrosion over time. All this will inevitably lead to damage to the wood. Yes, metal dowels are strong, but they do not combine with wood.

Wooden dowels are not inferior in strength to metal dowels, because... They are made from hard wood such as oak and birch. Most often, it is birch dowels that are found on the market, because they are more affordable in price than oak. They can be used for fastening all types of wooden houses. Wooden dowels will prevent torsion and deformation of the beam or log, without interfering with the uniform shrinkage of the log house, without preventing the crowns from sliding down.

The dowels are driven strictly vertically, from above, into the very center of the log or beam into a pre-drilled hole. One dowel grabs two logs at once, connecting the upper and lower crowns. The distance between the dowels should be 1.5 or 2 meters. The first dowel is driven in at a distance of 0.5 meters from the corner of the log house. The dowels throughout the log house should be staggered.

Screw jacks or shrinkage compensator

Screw jacks are necessary to prevent changes in horizontal level that can occur during house settlement. They are adjustable in height, installed on vertical logs, supports that are installed on the terrace, balcony, or upper floors. This element represents metal pin, a nut and two steel plates. Screw jacks are made from high-quality steel and are coated with a zinc coating on top, which prevents the formation of corrosion.

Sliding support

Sliding supports are intended for installing roof rafter systems. They consist of a sliding angle with a bracket and a hinge. The use of this fastener allows you to protect against possible displacement of rafter elements that may occur during shrinkage of the house. The thickness of the sliding support iron itself is 2 mm.

This is a more modern fastener. It is a screw with a spring. When it is screwed into logs or beams, it presses them firmly against each other, preventing the formation of cracks and gaps between the crowns. The “Force” spring unit will prevent the deformation of wooden materials and their torsion.

Also, this element provides the logs or beams with the necessary load. If lower crowns experience sufficient load, which is carried out by the upper wooden materials. Then for the logs located in the upper rows of the log house, the load comes only from the roof, this is not enough for them. The “Strength” spring knot is most often used specifically for securing the upper rims. Thus, the built house becomes durable, warm and airtight.

Build wooden house necessary using fasteners such as the “Force” spring unit, sliding supports, dowels and screw jacks. These elements will allow you to build a durable, strong wooden house that will be warm and safe. Assembling a wooden house with nails or fittings is a violation of the log house assembly technology, which can lead to unpleasant consequences.

Where in Moscow can you buy fasteners for building a wooden house?

You can buy all the fasteners listed in the article intended for wooden house construction from the PROGRESS company. Driving directions to the warehouse – our company’s store is located

The use of joinery and carpentry joints in construction requires not only special tool but also considerable experience.

Therefore, non-professionals often make such connections sloppy. The best option- use new types of metal fasteners

Most of the surviving monuments of wooden architecture were erected without a single nail, using only an axe, and this fact still causes admiration. But over the centuries, fastening systems made of metal and used for the construction of wooden houses have changed greatly, so today there is no point in repeating the “feats” of our ancestors.

It must be built simply, quickly and reliably. Let's look at the metal fasteners offered by manufacturers using the example of components and elements that can significantly simplify and speed up the connection of floor joists with beams or wooden walls, and at the same time some other operations.

1. CONNECTING ELEMENTS WITH PERFORATION

If beams and joists are invisible in the interior, then they can be connected using so-called beam shoes, produced, for example, by ESSVE. These elements are suitable for fastening wood not only to wood, but also to concrete or brickwork (using appropriate dowels).

They are mainly made of hot-dip galvanized steel with a thickness of 1.5 or 2 mm. but there are also more expensive products on the market made from stainless acid-resistant A6 steel. The shoes are available in two versions: with cuffs turned outward or inward. Price: from 50 to 500 rubles. for 1 piece

The manufacturer recommends fastening the beam shoes to the elements being connected with special anchor screws with a diameter of 5 mm (depending on the load, the latter can be inserted into all or some of the holes), and in case of a very heavy load or fixation to “stone” material, also use the holes for bolts. In addition to anchor shoes, the market includes perforated universal clamps (a), rafter fasteners (b), angles (c), plates (d), shown in the figure, etc.

THE MAIN ADVANTAGE OF FASTENERS WITH PERFORATION IS THE ACCELERATION OF INSTALLATION WITH A SIMULTANEOUS INCREASE IN THE STRENGTH INDICATORS OF CONNECTIONS ADVANTAGES OF ANCHOR SCREWS

Why do manufacturers of perforated fasteners suggest using anchor screws? How are the latter better than ordinary self-tapping screws or anchor (ruffed) nails used to secure beam shoes and other perforated metal elements? The advantages are due to the design features of anchor screws. Firstly, their flat head presses the metal element being fixed more tightly to the wood.

Secondly, the smooth cylindrical part located under the screw head has the same diameter of 5 mm as the holes in the perforated metal elements. It completely fills the hole and therefore completely transfers the load, and also works well for shearing. In addition, thanks to the tapered head, the screw is better centered. An ordinary self-tapping screw does not always transfer the load completely; it performs much worse at shearing. Well, the anchor nail cannot be dismantled without destroying the part of the wooden element into which it is driven. But the anchor screw is easily unscrewed and can be screwed into a wooden element in a new place.

2. METAL SYSTEMS “TEN-GROOT”

The element is made of aluminum and consists of two parts, one of which is equipped with a tenon, the second with a corresponding groove. They are fastened to each other according to the “dovetail” principle, which allows for reliable transmission of vertical and horizontal forces, to absorb tensile and compressive forces and even bending moments. The connection can be either visible or hidden, for which both metal parts are recessed into pre-milled grooves. The length of the Atlas node connector is 70-200 mm. Price - 1500-5500 rub. for 1 piece

EuroTec's main competitors on the Russian market are the Austrian companies PITZL and SHERPA Connection Systems, which produce a similar range of connecting elements. The SHERPA system is better known, providing a load-bearing capacity of connections from 5 to 280 kN - a special calculation program allows you to select fasteners for each specific case. Any connector consists of two aluminum parts, which are also fastened using the dovetail principle. The cost of SHERPA elements is from 800 to 12 thousand rubles. for 1 piece

Another competitor of EuroTec is the German company BB Stanz-und Umformtechnik. who developed the BB connecting unit. It is made of galvanized sheet steel with a thickness of U mm and consists, like its aluminum counterparts, of two parts, fixed to each other according to the dovetail principle. Both halves are attached to the wood with self-tapping screws, the number of which depends on the size of the element. BB connectors have a width of 70 mm and a length of 90. 125, 150 and 190 mm. The price is one of the most affordable today: 180-800 rubles. for 1 piece

Both parts of the Atlas connector are attached to the wooden parts with self-tapping screws, screwed at an angle of 90 and 45°. The connection is secured with a locking screw.

CONNECTORS ALLOW YOU TO SOLVE TASKS IN A FEW MINUTES THAT TAKE HOURS AND EVEN DAYS TO WORK IN CLASSICAL CONSTRUCTION TECHNOLOGIES

3. 3D SLATS

3D battens are suitable for connections (using nails or screws) not only wood-to-wood ( minimum thickness logs attached to the beam - 45 mm), but also “wood-concrete”, for which products are offered with enlarged holes for anchor bolts

4. HIDDEN ELEMENTS OF THE “HEDGEHOG” TYPE

These unusual products allow you to save not only the time required to assemble the unit, but also money, because connecting metal elements are not needed. Self-tapping screws are fully threaded, creating high pullout resistance, and are completely screwed into the wood at an angle of 30.45 or 60°. which radically changes the usual pattern of their work. In this case, the screws only work to pull out, which allows them to take on a significant part of the forces acting on the connection. Thus, it is possible to connect parts at an angle (a), to unite the elements. while reducing their deflection (b), strengthen the places of cutouts in beams and joists (c) (see figure below).

There are self-tapping screws with a cylindrical (screw diameter - 6.5, 8 and 10 mm) and countersunk (screw diameter - 8 or 11.3 mm) head. Length - 65-1000 mm. Price - 20-800 rub. for 1 piece To install screws with a length of less than 245 mm, no preliminary drilling is required, but for longer ones (to prevent slipping to the side), it is recommended to pre-drill holes for the self-tapping screw to a depth of up to 0.5 oz of its length.

A special ECS program, which can be freely downloaded on the website of a self-tapping screw manufacturer or a large retailer, helps you select the appropriate KonstruX screw, the fastening pattern of the elements, and also calculate the required number of screws.

6. SPECIAL SCREWS

Using a Hobotec self-tapping screw, massive boards, blockhouses or imitation timber are fastened. The head of the product is equipped with milling ribs and is easily recessed into the wood, and the tip is made in the form of a drill. A cutter in the middle of the length of the screw increases the diameter of the hole, allowing you to tighten the element being fastened more tightly. Self-tapping screws with a diameter of 3.2 mm and a length of 20 to 60 mm are made of ordinary coated steel (price - 1100-2200 rubles per pack of 500 pcs.) or stainless steel (price - 3500-7500 rubles per pack of 500 pcs. .).

The tension screw is also equipped with a cutter, but its tip is different - it has a special groove. turning a screw into a wood drill. The flat head has a large diameter and is equipped with a countersink head and a hexagonal slot. The self-tapping screw is coated with a special wax coating that reduces friction when screwing in. Product diameter - 3-12 mm. length - 30-600 mm. Price - from 300 to 5 thousand rubles. per pack of 500 pcs.

An adjusting screw is useful, for example, for attaching window and door frames or wooden sheathing to wood, concrete, brick or metal (the element can be equipped with two types of drilling tip). The self-tapping screw is screwed into the box and the wall or power element located behind it in one step.

In this case, the ring conical “spikes” located under the head of the screw are firmly fixed in the box (almost like a fishhook), thanks to which its position relative to the wall is easily adjusted by further screwing or unscrewing the fastening element. Length - from 60 to 125 mm. Price - from 2000 to 3500 rubles. per pack of 500 pcs.

Special elements for performing operations common in wooden house construction: adjusting screw for window frames or sheathing (a); tension screw (6); Hobotec self-tapping screw for fastening solid boards, blockhouses or imitation timber when covering a wooden house (c)

A self-tapping screw is a weather vane for fastening wooden sheathing to a steel base. Equipped with a drill tip and special “wings” (located above the tip), which expand the hole in the wood and break when drilling metal. As a result, having cut a thread in the metal, the self-tapping screw is fixed in it, and the head attracts the wooden element to the metal. Length: 32-125 mm. Price: from 500 to 2500 rubles. per pack of 500 pcs.

What kind of fasteners should be used for lumber? Wood is a fairly soft material, especially when compared with other types of wood. However physical properties wooden parts used in construction can vary greatly depending on the percentage of their moisture content, the species used, the growing conditions of the trees... The structure is not uniform even different areas the same log. In any case, the fastening element must adhere well to the fibers and reliably fix any parts. To increase the friction force, nails are often knurled or roughened, and self-tapping screws have coarse threads.

Reliability of wood fasteners

Most wood fasteners in Moscow are made from galvanized and phosphated steel or metals that do not rust (for example, there are nails made of aluminum and copper). Only some types of products are made of ferrous metal, but only those that are used in rough structures - construction nails, hardened roofing staples. Protective covering allows you to significantly increase service life fastening elements, but, in addition, the aesthetic properties of the product are improved by an order of magnitude, because red spots and stains from rust will be eliminated.

The design of modern fasteners is thought out to the smallest detail. So, there are dozens of types of self-tapping screws that are designed for certain jobs, each of them has its own characteristics. Let's say a roofing fastener has a drill on the tip that can be used to drill through sheet metal, and a large rubberized washer. And structural yellow self-tapping screws have complex body threads (sometimes incomplete) and a special tip. The finishing nail has a very small head, while the galvanized nail for fastening OSB, on the contrary, has a rather large head. There are fastening products with a conical head, and others with a flat one. Lots of length options available.

Almost all of these fasteners (including perforated ones) are used under load, so they must be resistant to bending and shearing forces. High-quality wood fasteners do not break; in extreme cases, they can only bend. You can choose products for certain jobs different thicknesses, this applies to both nails/screws and perforated plates/corners.

Types of fasteners for wood

Nails

This is perhaps one of the most famous and proven types of components for construction work. This wood fastener has the most affordable price, but it is practical and functional. A nail is a metal rod cut from wire, which has a point at one end and a flat head at the other.

When used, the product is hammered with a regular hammer, or can be combined into strips and loaded into a nail gun. Nails can be used alone or in combination with perforated fasteners.

The size of the head differs in size, depending on whether the nail should be recessed or press the part more reliably. The rod may have notches to increase friction forces, because it is with their help that the nails are held in the wood. The length (as well as the thickness) of the nail is selected according to the nature of the connection and the type of loads experienced by the unit.

Depending on the purpose for which nails are intended, they are divided into several main types. If we talk about construction, then this is:

- Black construction nails,

- Galvanized with a large head,

- Ruffed,

- Screw,

- Finishing,

- Tolevye,

- Slate.

Self-tapping screws

This modern fasteners, has high efficiency and at the same time very practical. The cost of fasteners for this type of wood is higher than that of nails, but it also has many advantages.

The beauty of a self-tapping screw is that it takes advantage of the plasticity of wood. That is, it allows screwing in without preliminary drilling. Thanks to the wide thread pitch and increased height (for example, metal screws have more frequent and lower threads), this fastener fits tightly into any wood fibers and stays there perfectly. At the same time, such a connection remains collapsible, while those knocked down with nails wooden parts It is extremely rare to be separated without damage.

The design of the thread and tip is designed for easy entry into wood. A drill at the end of wood screws is usually not used. The cap is made with a cone for recessing, or flat, for the “press washer” and “roofing screw” types. The thread can be continuous or partial. There are many options for thickness and length of products.

To use self-tapping screws, you need a drill or screwdriver, although, theoretically, small items in small quantities can be screwed in with a screwdriver. To transmit rotation from the tool, there are slots on the head of the self-tapping screw. The shape of the slots may vary. As a rule, PH or PZ formats are used - this must be taken into account when choosing a bit.

Among the many types of wood screws, the most popular are:

- phosphated (black);

- galvanized (yellow);

- roofing (white and painted);

- screws with a hexagonal or profile head (including: capercaillie, with a ring, with a hook, L-shaped crutch screw, capercaillie with a spring).

Threaded metric connection types

Nails and screws are not the only components that can be used to assemble wooden structures. The most loaded or most voluminous units are twisted using bolts and studs. Together with nuts and washers, these hardware allow you to obtain the most reliable fixation, because you can press the parts very tightly against each other, use rods of increased diameter (and therefore very strong). An obvious advantage is the ability to disassemble and reassemble structures several times.

Studs and bolts are installed through a through hole, which must be drilled in each of the parts being fastened. Direct fixation is carried out by tightening the nuts. Large washers increase the bearing area and prevent the nuts/heads from sinking into the wood.

Perforated fasteners

This type of fastener is designed to speed up installation wooden elements building. Thanks to such products, it became possible to avoid the technically complex (and labor-intensive) production of mortises and locks in wood. If cutting wood actually underestimated the cross-section of parts, then perforated products made it possible to perform end-to-end assembly, and with an increase in the reliability of the assembly. Therefore, there is no need to increase the cross-section of lumber, as before. Accordingly, it will be possible to unload the house and save money, although before making calculations it seems that buying perforated fasteners for wood is a rather expensive solution.

Another advantage similar products lies in increasing the speed of construction. Connections using angles and plates can be easily made by non-professionals, because all that is needed is to cut the beam or board more or less exactly to length.

Perforated fasteners are available in a wide range. They are combined into a system and cover all the needs of modern wooden and general construction. They are made from sheet metal thickness from one and a half to 5 mm, which contains a large number of holes (small round, large for anchors, long slots for sliding fixations). All products are galvanized and completely ready for use. Among all the fasteners with perforation, there are several types according to their design and scope of use, first of all, these are corners, plates, supports, and tapes.

Price list

Prices for wood fasteners

| Product name | Name of option | The price of the product | ||

|---|---|---|---|---|

| Adhesive for plywood and parquet Artelit 21 kg | Bucket 21 kg | RUB 4,200.00 | ||

| Roofing bat | 6 mm | RUB 60.00 | ||

| 8 mm | 65.00 RUR | |||

| 10 mm | RUB 70.00 | |||

| 12 mm | RUB 75.00 | |||

| 13 mm | RUR 80.00 | |||

| 17 mm | 90.00 RUR | |||

| 25 mm | RUB 220.00 | |||

| 30 mm | RUB 220.00 | |||

| 40 mm | RUB 220.00 | |||

| 50 mm | RUB 220.00 | |||

| Polyurethane foam | Macroflex (professional) | RUB 360.00 | ||

| Macroflex | RUR 300.00 | |||

| Titan (prof.) | RUB 380.00 | |||

| Titanium | RUB 320.00 | |||

| Wooden dowel | with a knot | 14.00 RUR | ||

| without a hitch | 18.00 RUR | |||

| Yellow wood screw | 3x25 mm | RUB 380.00 | ||

| 3x30mm | RUB 350.00 | |||

| 3x35mm | RUB 350.00 | |||

| 3x40 mm | RUB 350.00 | |||

| 3.5x16mm | RUB 350.00 | |||

| 3.5x40 mm | RUB 350.00 | |||

| 4x35mm | RUB 330.00 | |||

| 4x50 mm | RUB 330.00 | |||

| 4x60 mm | RUB 330.00 | |||

| 4x70 mm | RUB 330.00 | |||

| 5x40 mm | RUB 330.00 | |||

| 5x50mm | RUB 330.00 | |||

| 5x60mm | RUB 330.00 | |||

| 5x70 mm | RUB 330.00 | |||

| 5x80mm | RUB 330.00 | |||

| 5x100mm | RUB 330.00 | |||

| 5x120 mm | RUB 330.00 | |||

| 6x40 mm | RUB 330.00 | |||

| 6x50 mm | RUB 330.00 | |||

| 6x60 mm | RUB 330.00 | |||

| Black wood self-tapping screw | 3.5x16 mm | RUB 240.00 | ||

| 3.5x19 mm | RUB 240.00 | |||

| 3.5x25 mm | RUB 240.00 | |||

| 3.5x32 mm | RUB 240.00 | |||

| 3.5x35 mm | RUB 240.00 | |||

| 3.5x41 mm | RUB 240.00 | |||

| 3.5x45 mm | RUB 240.00 | |||

| 3.5x51 mm | RUB 240.00 | |||

| 3.5x55 mm | RUB 240.00 | |||

| 4.2x64 mm | RUB 240.00 | |||

| 4.2x70 mm | RUB 240.00 | |||

| 4.2x76 mm | RUB 240.00 | |||

| 4.8x90 mm | RUB 240.00 | |||

| 4.8x95 mm | RUB 240.00 | |||

| 4.8x100 mm | RUB 240.00 | |||

| 4.8x127 mm | RUB 240.00 | |||

| 4.8x140 mm | RUB 240.00 | |||

| 4.8x150 mm | RUB 240.00 | |||

| Black construction nails | 1.8x20mm | 98.00 RUR | ||

| 1.8x25mm | 98.00 RUR | |||

| 2.5x40 mm | 98.00 RUR | |||

| 2.5x50 mm | 98.00 RUR | |||

| 2.5x60 mm | 98.00 RUR | |||

| 3x70 mm | 98.00 RUR | |||

| 3x80 mm | 98.00 RUR | |||

| 3.5x90 mm | 98.00 RUR | |||

| 4x100 mm | 98.00 RUR | |||

| 4x120 mm | 98.00 RUR | |||

| 5x150 mm | 98.00 RUR | |||

| 8x250 mm | 98.00 RUR | |||

| 8x300 mm | 98.00 RUR | |||

| Sliding support for rafters | 40x120 mm | RUB 70.00 | ||

| 40x160 mm | RUR 80.00 | |||

| 40x200 mm | 90.00 RUR | |||

| Timber staples, hardened | 6x150 mm | 20.00 RUR | ||

| 6x200 mm | 22.00 RUR | |||

| 6x250 mm | 24.00 RUR | |||

| 8x200 mm | 26.00 RUR | |||

| 8x250 mm | 28.00 RUR | |||

| 8x300 mm | RUB 30.00 | |||

| Perforated metal corner | 20x40 mm | standard | 8.00 RUR | |

| 40x40 mm | standard | 14.00 RUR | ||

| 50x35 mm | reinforced | 15.00 RUR | ||

| 50x50 mm | standard | 20.00 RUR | ||

| 70x55 mm | reinforced | 26.00 RUR | ||

| 90x40 mm | reinforced | RUR 32.00 | ||

| 90x65 mm | reinforced | RUR 34.00 | ||

| 105x90 mm | reinforced | RUB 47.00 | ||

| 130x100 mm | reinforced | RUB 102.00 | ||

| 140x140 mm | reinforced | RUB 120.00 | ||

| Perforated mounting plate | 100 x 35 x 2 mm | 18.50 RUR | ||

| 140 x 55 x 2 mm | RUB 29.00 | |||

| 180 x 40 x 2 mm | RUB 39.00 | |||

| 180 x 65 x 2 mm | RUB 49.00 | |||

| 210 x 90 x 2 mm | RUB 59.00 | |||

| Beam support | 110 mm | 50 mm | RUR 80.00 | |

| 140 mm | 50 mm | 90.00 RUR | ||

| 165 mm | 50 mm | RUB 100.00 | ||

| 180 mm | 50 mm | RUB 110.00 | ||

| 100 mm | 100 mm | RUB 120.00 | ||

| 160 mm | 100 mm | RUB 130.00 | ||

| 200 mm | 100 mm | RUB 140.00 | ||

| 150 mm | 150 mm | RUB 150.00 | ||

| Screw for fastening joists and slats (capercaillie) | 60 mm | 6 mm | RUB 40.00 | |

| 80 mm | 6 mm | RUB 50.00 | ||

| 100 mm | 6 mm | RUB 60.00 | ||

| 50 mm | 8 mm | RUB 50.00 | ||

| 60 mm | 8 mm | RUB 70.00 | ||

| 80 mm | 8 mm | RUB 85.00 | ||

| 100 mm | 8 mm | RUB 100.00 | ||

| 120 mm | 8 mm | RUB 120.00 | ||

| 130 mm | 8 mm | RUB 140.00 | ||

| 160 mm | 8 mm | RUB 160.00 | ||

| 180 mm | 8 mm | RUR 195.00 | ||

| 200 mm | 8 mm | RUB 240.00 | ||

| 60 mm | 10 mm | RUB 120.00 | ||

| 70 mm | 10 mm | RUB 140.00 | ||

| 80 mm | 10 mm | RUB 160.00 | ||

| 100 mm | 10 mm | RUB 180.00 | ||

| 120 mm | 10 mm | RUB 220.00 | ||

| 160 mm | 10 mm | RUB 260.00 | ||

| 180 mm | 10 mm | RUB 290.00 | ||

| 200 mm | 10 mm | RUB 320.00 | ||

| 220 mm | 10 mm | RUB 350.00 | ||

| 240 mm | 10 mm | RUB 390.00 | ||

| 260 mm | 10 mm | RUB 420.00 | ||

| 120 mm | 12 mm | RUB 290.00 | ||

| 160 mm | 12 mm | RUB 370.00 | ||

| 180 mm | 12 mm | RUB 390.00 | ||

| 200 mm | 12 mm | RUB 410.00 | ||

| 240 mm | 12 mm | RUB 480.00 | ||

| 260 mm | 12 mm | RUB 500.00 | ||

| 280 mm | 12 mm | RUB 580.00 | ||

| 300 mm | 12 mm | RUB 720.00 | ||

| Screw (capercaillie) with spring | 10x200 mm | RUB 124.00 | ||

| 10x220 mm | RUB 134.00 | |||

| 10x180 mm | RUB 116.00 | |||

| Ring screw | 8x120 mm | 25.00 RUR | ||

| 8x160 mm | RUB 30.00 | |||

| 10x220 mm | RUB 50.00 | |||

| Bolt | M6 | RUB 180.00 | ||

| M8 | RUB 180.00 | |||

| M10 | RUB 180.00 | |||

| M12 | RUB 180.00 | |||

| M14 | RUB 180.00 | |||

| M16 | RUB 180.00 | |||

| M18 | RUB 180.00 | |||

| M20 | RUB 180.00 | |||

| M22 | RUB 180.00 | |||

| M24 | RUB 180.00 | |||

| Washer | M6 | RUR 195.00 | ||

| M8 | RUR 195.00 | |||

| M10 | RUR 195.00 | |||

| M12 | RUR 195.00 | |||

| M14 | RUR 195.00 | |||

| M16 | RUR 195.00 | |||

| M18 | RUR 195.00 | |||

| M20 | RUR 195.00 | |||

| M22 | RUR 195.00 | |||

| M24 | RUR 195.00 | |||

| screw | M6 | RUB 190.00 | ||

| M8 | RUB 190.00 | |||

| M10 | RUB 190.00 | |||

| M12 | RUB 190.00 | |||

| M14 | RUB 190.00 | |||

| M16 | RUB 190.00 | |||

| M18 | RUB 190.00 | |||

| M20 | RUB 190.00 | |||

| M22 | RUB 190.00 | |||

| M24 | RUB 190.00 | |||

| Threaded rod | M6 | 1m | RUB 39.00 | |

| M8 | 1m | 58.00 RUR | ||

| M10 | 1m | RUB 70.00 | ||

| M12 | 1m | 90.00 RUR | ||

| M14 | 1m | RUB 129.00 | ||

| M16 | 1m | RUR 155.00 | ||

| M20 | 1m | RUB 245.00 | ||

| M22 | 1m | RUB 310.00 | ||

| M24 | 1m | RUB 380.00 | ||

| M6 | 2 m | RUB 78.00 | ||

| M8 | 2 m | RUB 116.00 | ||

| M10 | 2 m | RUB 140.00 | ||

| M12 | 2 m | RUB 180.00 | ||

| M14 | 2 m | RUB 258.00 | ||

| M16 | 2 m | RUB 310.00 | ||

| M20 | 2 m | RUR 490.00 | ||

| M22 | 2 m | RUB 620.00 | ||

| M24 | 2 m | RUR 760.00 | ||

| Finishing nails | 30 mm | 1 kg | RUB 200.00 | |

| 40 mm | 1 kg | RUB 200.00 | ||

| 50 mm | 1 kg | RUB 200.00 | ||

| 60 mm | 1 kg | RUB 200.00 | ||

| 30 mm | 5 kg | RUB 1,000.00 | ||

| 40 mm | 5 kg | RUB 1,000.00 | ||

| 50 mm | 5 kg | RUB 1,000.00 | ||

| 60 mm | 5 kg | RUB 1,000.00 | ||

| 100 mm | 1 kg | RUB 200.00 | ||

| 120 mm | 1 kg | RUB 200.00 | ||

| 150 mm | 1 kg | RUB 200.00 | ||

| 32 mm | 5 kg | RUB 1,000.00 | ||

| 40 mm | 5 kg | RUB 1,000.00 | ||

| 50 mm | 5 kg | RUB 1,000.00 | ||

| 60 mm | 5 kg | RUB 1,000.00 | ||

| 70 mm | 5 kg | RUB 1,000.00 | ||

| 80 mm | 5 kg | RUB 1,000.00 | ||

| 100 mm | 5 kg | RUB 1,000.00 | ||

| 120 mm | 5 kg | RUB 1,000.00 | ||

| Galvanized roofing self-tapping screw | 4.8x29 mm | Metal + Wood | 21.00 RUR | |

| 4.8x38 mm | Metal + Wood | 24.00 RUR | ||

| 4.8x51 mm | Metal + Wood | 26.00 RUR | ||

| 4.8x76 mm | Metal + Wood | 28.00 RUR | ||

| 5.5x19 mm | Metal | 21.00 RUR | ||

| 5.5x25 mm | Metal | 23.00 RUR | ||

| 5.5x32 mm | Metal | 26.00 RUR | ||

| 5.5x51 mm | Metal | 28.00 RUR | ||

| 5.5x76 mm | Metal | RUR 34.00 | ||

| Painted roofing screw | RAL 8017 brown | 4.8x29 mm | Metal + Wood | 26.00 RUR |

| RAL 6005 green | 4.8x29 mm | Metal + Wood | 26.00 RUR | |

| RAL 3005 cherry | 4.8x29 mm | Metal + Wood | 26.00 RUR | |

| RAL 8017 brown | 4.8x38 mm | Metal + Wood | 28.00 RUR | |

| RAL 6005 green | 4.8x38 mm | Metal + Wood | 28.00 RUR | |

| RAL 3005 cherry | 4.8x38 mm | Metal + Wood | 28.00 RUR | |

| RAL 8017 brown | 4.8x51 mm | Metal + Wood | RUB 35.00 | |

| RAL 6005 green | 4.8x51 mm | Metal + Wood | RUB 35.00 | |

| RAL 3005 cherry | 4.8x51 mm | Metal + Wood | RUB 35.00 | |

| RAL 8017 brown | 4.8x76 mm | Metal + Wood | 45.00 RUR | |

| RAL 6005 green | 4.8x76 mm | Metal + Wood | 45.00 RUR | |

| RAL 3005 cherry | 4.8x76 mm | Metal + Wood | 45.00 RUR | |

| RAL 8017 brown | 5.5x19 mm | Metal | 27.00 RUR | |

| RAL 6005 green | 5.5x19 mm | Metal | 27.00 RUR | |

| RAL 3005 cherry | 5.5x19 mm | Metal | 27.00 RUR | |

| RAL 8017 brown | 5.5x25 mm | Metal | RUR 32.00 | |

| RAL 6005 green | 5.5x25 mm | Metal | RUR 32.00 | |

| RAL 3005 cherry | 5.5x25 mm | Metal | RUR 32.00 | |

| RAL 8017 brown | 5.5x32 mm | Metal | RUR 37.00 | |

| RAL 6005 green | 5.5x32 mm | Metal | RUR 37.00 | |

| RAL 3005 cherry | 5.5x32 mm | Metal | RUR 37.00 | |

| RAL 8017 brown | 5.5x51 mm | Metal | RUB 43.00 | |

| RAL 6005 green | 5.5x51 mm | Metal | RUB 43.00 | |

| RAL 3005 cherry | 5.5x51 mm | Metal | RUB 43.00 | |

| RAL 8017 brown | 5.5x76 mm | Metal | RUB 50.00 | |

| RAL 6005 green | 5.5x76 mm | Metal | RUB 50.00 | |

| RAL 3005 cherry | 5.5x76 mm | Metal | RUB 50.00 | |

| Sliding mounting angle | 40x120 mm | RUB 60.00 | ||

| 60x220 mm | 90.00 RUR | |||

| Staples for construction manual stapler | 6 mm | RUB 40.00 | ||

| 8 mm | RUB 50.00 | |||

| 10 mm | RUB 60.00 | |||

| 12 mm | RUB 70.00 | |||

| 14 mm | RUR 80.00 |