Construction of a private house is a very difficult process from start to finish. One of the main issues this process is the choice of construction raw materials. This choice must be very competent and thoughtful, because most of the life in the new home depends on it. What stands apart in this choice is the concept of thermal conductivity of materials. It will determine how warm and comfortable the house will be.

Thermal conductivity is an ability physical bodies(and the substances from which they are made) transfer thermal energy. Explaining more in simple language, this is the transfer of energy from a warm place to a cold one. For some substances, such transfer will occur quickly (for example, most metals), and for some, on the contrary, very slowly (rubber).

To put it even more clearly, in some cases, materials with a thickness of several meters will conduct heat much better than other materials with a thickness of several tens of centimeters. For example, a few centimeters of drywall can replace an impressive brick wall.

Based on this knowledge, it can be assumed that the most correct choice of materials will be with low values of this quantity so that the house does not cool down quickly. For clarity, let us denote percentage heat loss in different areas Houses:

What does thermal conductivity depend on?

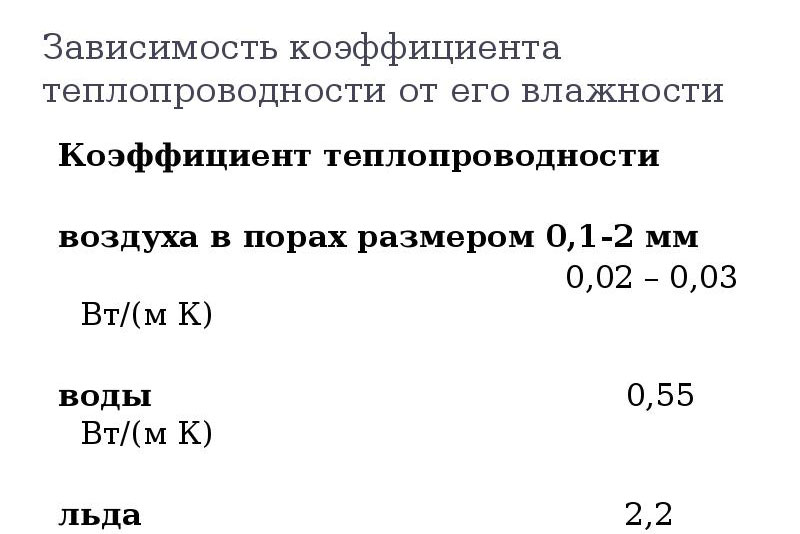

Values of this quantity may depend on several factors. For example, the thermal conductivity coefficient, which we will talk about separately, the humidity of building materials, density, and so on.

- Materials with high densities have, in turn, a high ability to transfer heat due to the dense accumulation of molecules inside the substance. Porous materials, on the contrary, will heat up and cool down more slowly.

- Heat transfer is also affected by the humidity of materials. If the materials get wet, their heat transfer will increase.

- Also, the structure of the material greatly influences this indicator. For example, a tree with transverse and longitudinal grains will have different meanings thermal conductivity.

- The indicator also changes with changes in parameters such as pressure and temperature. With increasing temperature it increases, and with increasing pressure, on the contrary, it decreases.

Coefficient of thermal conductivity

For quantification such a parameter are used special thermal conductivity coefficients, strictly declared in SNIP. For example, the thermal conductivity coefficient of concrete is 0.15-1.75 W/(m*C) depending on the type of concrete. Where C is degrees Celsius. On this moment there are coefficient calculations for almost everyone existing types construction raw materials used in construction. Thermal conductivity coefficients building materials very important in any architectural and construction work.

For convenient selection of materials and their comparison, special tables of thermal conductivity coefficients are used, developed in accordance with SNIP standards (building codes and regulations). Thermal conductivity of building materials, the table of which will be given below, is very important in the construction of any objects.

- Wood materials. For some materials, the parameters will be given both along the fibers (Index 1, and across – index 2)

- Various types of concrete.

- Various types of construction and decorative bricks.

Calculation of insulation thickness

From the above tables we see how different the heat conductivity coefficients can be for different materials. To calculate the thermal resistance of the future wall, there is a simple formula, which connects the thickness of the insulation and its thermal conductivity coefficient.

From the above tables we see how different the heat conductivity coefficients can be for different materials. To calculate the thermal resistance of the future wall, there is a simple formula, which connects the thickness of the insulation and its thermal conductivity coefficient.

R = p / k, where R is the thermal resistance index, p is the layer thickness, k is the coefficient.

From this formula it is easy to extract the formula for calculating the thickness of the insulation layer for the required thermal resistance. P = R * k. Thermal resistance value is different for each region. There is also a special table for these values, where they can be viewed when calculating the thickness of the insulation.

Now let's give some examples the most popular insulation materials and their technical characteristics.

The term thermal conductivity is applied to the ability of materials to transmit thermal energy from hot to cold areas. Thermal conductivity is based on the movement of particles within substances and materials. The ability to transfer heat energy in quantitative measurement is the thermal conductivity coefficient. The cycle of thermal energy transfer, or heat exchange, can take place in any substance with an unequal distribution of different temperature sections, but the thermal conductivity coefficient depends on the pressure and temperature in the material itself, as well as on its state - gaseous, liquid or solid.

Physically, the thermal conductivity of materials is equal to the amount of heat that flows through a homogeneous object of established dimensions and area over a certain time period at a specified temperature difference (1 K). In the SI system, a unit indicator, which has a thermal conductivity coefficient, is usually measured in W/(m K).

How to calculate thermal conductivity using Fourier's law

In a given thermal mode The flux density during heat transfer is directly proportional to the vector of the maximum increase in temperature, the parameters of which vary from one area to another, and modulo with the same rate of increase in temperature in the direction of the vector:

q → = − ϰ x grad x (T), where:

- q → – the direction of the density of an object transmitting heat, or the volume of heat flow that flows through an area for a given time unit through a certain area, perpendicular to all axes;

- ϰ – specific thermal conductivity coefficient of the material;

- T – temperature of the material.

When applying Fourier's law, the inertia of the flow of thermal energy is not taken into account, which means that we mean the instantaneous transfer of heat from any point to any distance. Therefore, the formula cannot be used to calculate heat transfer during processes that have a high repetition rate. This is ultrasonic radiation, the transfer of thermal energy by shock or pulse waves, etc. There is a solution according to Fourier's law with a relaxation term:

τ x ∂ q / ∂ t = − (q + ϰ x ∇T) .

If relaxation τ is instantaneous, then the formula turns into Fourier’s law.

Approximate table of thermal conductivity of materials:

| The basis | Thermal conductivity value, W/(m K) |

| Hard graphene | 4840 + / – 440 – 5300 + / – 480 |

| Diamond | 1001-2600 |

| Graphite | 278,4-2435 |

| Boron arsenide | 200-2000 |

| SiC | 490 |

| Ag | 430 |

| Cu | 401 |

| BeO | 370 |

| Au | 320 |

| Al | 202-236 |

| AlN | 200 |

| BN | 180 |

| Si | 150 |

| Cu 3 Zn 2 | 97-111 |

| Cr | 107 |

| Fe | 92 |

| Pt | 70 |

| Sn | 67 |

| ZnO | 54 |

| Black steel | 47-58 |

| Pb | 35,3 |

| Stainless steel | Thermal conductivity of steel – 15 |

| SiO2 | 8 |

| High quality heat resistant pastes | 5-12 |

| Granite (consists of SiO 2 68-73%; Al 2 O 3 12.0-15.5%; Na 2 O 3.0-6.0%; CaO 1.5-4.0%; FeO 0.5- 3.0%; Fe 2 O 3 0.5-2.5%; K 2 O 0.5-3.0%; MgO 0.1-1.5%; TiO 2 0.1-0.6% ) | 2,4 |

| Concrete mortar without aggregates | 1,75 |

| Concrete mortar with crushed stone or gravel | 1,51 |

| Basalt (consists of SiO 2 – 47-52%, TiO 2 – 1-2.5%, Al2O 3 – 14-18%, Fe 2 O 3 – 2-5%, FeO – 6-10%, MnO – 0, 1-0.2%, MgO – 5-7%, CaO – 6-12%, Na 2 O – 1.5-3%, K 2 O – 0.1-1.5%, P 2 O 5 – 0.2-0.5%) | 1,3 |

| Glass (consists of SiO 2, B 2 O 3, P 2 O 5, TeO 2, GeO 2, AlF 3, etc.) | 1-1,15 |

| Heat-resistant paste KPT-8 | 0,7 |

| Concrete mortar filled with sand, without crushed stone or gravel | 0,7 |

| The water is clean | 0,6 |

| Silicate or red brick | 0,2-0,7 |

| Oils silicone based | 0,16 |

| Foam concrete | 0,05-0,3 |

| Aerated concrete | 0,1-0,3 |

| Tree | Thermal conductivity of wood – 0.15 |

| Oils petroleum based | 0,125 |

| Snow | 0,10-0,15 |

| PP with flammability group G1 | 0,039-0,051 |

| EPPU with flammability group G3, G4 | 0,03-0,033 |

| Glass wool | 0,032-0,041 |

| Stone wool | 0,035-0,04 |

| Air atmosphere (300 K, 100 kPa) | 0,022 |

| Gel air based | 0,017 |

| Argon (Ar) | 0,017 |

| Vacuum environment | 0 |

The given thermal conductivity table takes into account heat transfer through thermal radiation and particle heat exchange. Since a vacuum does not transfer heat, it flows through solar radiation or another type of heat generation. In gas or liquid medium layers with different temperatures are mixed artificially or in a natural way.

When calculating the thermal conductivity of a wall, it is necessary to take into account that heat transfer through wall surfaces varies due to the fact that the temperature in the building and outside is always different, and depends on the area of all surfaces of the house and on the thermal conductivity of building materials.

To quantify thermal conductivity, a value such as the thermal conductivity coefficient of materials was introduced. It shows how a particular material is capable of transferring heat. The higher this value, for example the thermal conductivity coefficient of steel, the more efficiently the steel will conduct heat.

- When insulating a house made of wood, it is recommended to choose building materials with a low coefficient.

- If the wall is brick, then with a coefficient value of 0.67 W/(m2 K) and a wall thickness of 1 m and its area of 1 m2, with a difference in external and internal temperatures of 1 0 C, the brick will transmit 0.67 W of energy. With a temperature difference of 10 0 C, the brick will transmit 6.7 W, etc.

The standard value of the thermal conductivity coefficient of thermal insulation and other building materials is correct for a wall thickness of 1 m. To calculate the thermal conductivity of a surface of a different thickness, the coefficient should be divided by the selected value of the wall thickness (meters).

In SNiP and when carrying out calculations, the term “thermal resistance of the material” appears; it means reverse thermal conductivity. That is, with a thermal conductivity of a foam sheet of 10 cm and its thermal conductivity of 0.35 W/(m 2 K), the thermal resistance of the sheet is 1 / 0.35 W/(m 2 K) = 2.85 (m 2 K)/W.

Below is a table of thermal conductivity for popular building materials and thermal insulators:

| Construction materials | Thermal conductivity coefficient, W/(m 2 K) |

| Alabaster slabs | 0,47 |

| Al | 230 |

| Asbestos-cement slate | 0,35 |

| Asbestos (fiber, fabric) | 0,15 |

| Asbestos cement | 1,76 |

| Asbestos-cement products | 0,35 |

| Asphalt | 0,73 |

| Asphalt for flooring | 0,84 |

| Bakelite | 0,24 |

| Concrete with crushed stone filler | 1,3 |

| Sand filled concrete | 0,7 |

| Porous concrete - foam and aerated concrete | 1,4 |

| Solid concrete | 1,75 |

| Thermal insulating concrete | 0,18 |

| Bitumen mass | 0,47 |

| Paper materials | 0,14 |

| Loose mineral wool | 0,046 |

| Heavy mineral wool | 0,05 |

| Cotton wool is a cotton-based heat insulator | 0,05 |

| Vermiculite in slabs or sheets | 0,1 |

| Felt | 0,046 |

| Gypsum | 0,35 |

| Alumina | 2,33 |

| Gravel aggregate | 0,93 |

| Granite or basalt aggregate | 3,5 |

| Wet soil, 10% | 1,75 |

| Wet soil, 20% | 2,1 |

| Sandstones | 1,16 |

| Dry soil | 0,4 |

| Compacted soil | 1,05 |

| Tar mass | 0,3 |

| Construction board | 0,15 |

| Plywood sheets | 0,15 |

| Hardwood | 0,2 |

| Chipboard | 0,2 |

| Duralumin products | 160 |

| Reinforced concrete products | 1,72 |

| Ash | 0,15 |

| Limestone blocks | 1,71 |

| Mortar on sand and lime | 0,87 |

| Foamed resin | 0,037 |

| Natural stone | 1,4 |

| Cardboard sheets made of several layers | 0,14 |

| Porous rubber | 0,035 |

| Rubber | 0,042 |

| Rubber with fluorine | 0,053 |

| Expanded clay concrete blocks | 0,22 |

| Red brick | 0,13 |

| Hollow brick | 0,44 |

| Solid brick | 0,81 |

| Solid brick | 0,67 |

| Slag brick | 0,58 |

| Silica based slabs | 0,07 |

| Brass products | 110 |

| Ice at a temperature of 0 0 C | 2,21 |

| Ice at a temperature of -20 0 C | 2,44 |

| Deciduous tree at 15% humidity | 0,15 |

| Copper products | 380 |

| Mipora | 0,086 |

| Sawdust for filling | 0,096 |

| Dry sawdust | 0,064 |

| PVC | 0,19 |

| Foam concrete | 0,3 |

| Polystyrene foam brand PS-1 | 0,036 |

| Polystyrene foam brand PS-4 | 0,04 |

| Polystyrene foam grade PVC-1 | 0,05 |

| Polystyrene foam brand FRP | 0,044 |

| PPU brand PS-B | 0,04 |

| PPU brand PS-BS | 0,04 |

| Polyurethane foam sheet | 0,034 |

| Polyurethane foam panel | 0,024 |

| Lightweight foam glass | 0,06 |

| Heavy foam glass | 0,08 |

| Glassine products | 0,16 |

| Perlite products | 0,051 |

| Slabs on cement and perlite | 0,085 |

| Wet sand 0% | 0,33 |

| Wet sand 0% | 0,97 |

| Wet sand 20% | 1,33 |

| Burnt stone | 1,52 |

| Ceramic tile | 1,03 |

| PMTB-2 brand tiles | 0,035 |

| Polystyrene | 0,081 |

| Foam rubber | 0,04 |

| Cement based mortar without sand | 0,47 |

| Natural cork slab | 0,042 |

| Lightweight natural cork sheets | 0,034 |

| Heavy sheets of natural cork | 0,05 |

| Rubber products | 0,15 |

| Ruberoid | 0,17 |

| Slate | 2,100 |

| Snow | 1,5 |

| Coniferous wood with a moisture content of 15% | 0,15 |

| Coniferous resinous wood with a moisture content of 15% | 0,23 |

| Steel products | 52 |

| Glass products | 1,15 |

| Glass wool insulation | 0,05 |

| Fiberglass insulation | 0,034 |

| Fiberglass products | 0,31 |

| Shavings | 0,13 |

| Teflon coating | 0,26 |

| Tol | 0,24 |

| Cement mortar board | 1,93 |

| Cement-sand mortar | 1,24 |

| Cast iron products | 57 |

| Slag in granules | 0,14 |

| Ash slag | 0,3 |

| Cinder blocks | 0,65 |

| Dry plaster mixtures | 0,22 |

| Cement based plaster mortar | 0,95 |

| Ebonite products | 0,15 |

In addition, it is necessary to take into account the thermal conductivity of insulation materials due to their jet heat flows. In a dense environment, it is possible to “transfuse” quasiparticles from one heated building material to another, colder or warmer, through submicron-sized pores, which helps distribute sound and heat, even if there is an absolute vacuum in these pores.

Thermal conductivity- the ability of a material to transfer heat from one part to another due to the thermal movement of molecules. Heat transfer in a material is carried out by conduction (by contact of particles of the material), convection (the movement of air or other gas in the pores of the material) and radiation.

Thermal conductivity depends on the average density of the material, its structure, porosity, humidity and average temperature layer of material. As the average density of the material increases, thermal conductivity increases. The higher the porosity, i.e. less average density material, the lower the thermal conductivity. With increasing humidity of the material, thermal conductivity increases sharply, while its thermal insulation properties. Therefore everything thermal insulation materials in a thermal insulation structure, they are protected from moisture by a covering layer - vapor barrier.

Comparative data of building materials with the same thermal conductivity

Thermal conductivity coefficient of materials

|

Material |

Thermal conductivity coefficient, W/m*K |

| Alabaster slabs | 0,47 |

| Asbestos (slate) | 0,35 |

| Fibrous asbestos | 0,15 |

| Asbestos cement | 1,76 |

| Asbestos cement slabs | 0,35 |

| Thermal insulating concrete | 0,18 |

| Bitumen | 0,47 |

| Paper | 0,14 |

| Light mineral wool | 0,045 |

| Heavy mineral wool | 0,055 |

| Cotton wool | 0,055 |

| Vermiculite sheets | 0,1 |

| Woolen felt | 0,045 |

| Construction gypsum | 0,35 |

| Alumina | 2,33 |

| Gravel (filler) | 0,93 |

| Granite, basalt | 3,5 |

| Soil 10% water | 1,75 |

| Soil 20% water | 2,1 |

| Sandy soil | 1,16 |

| The soil is dry | 0,4 |

| Compacted soil | 1,05 |

| Tar | 0,3 |

| Wood - boards | 0,15 |

| Wood - plywood | 0,15 |

| Hardwood | 0,2 |

| Wood-chip chipboard | 0,2 |

| Wood ash | 0,15 |

| Iporka (foamed resin) | 0,038 |

| Stone | 1,4 |

| Multilayer construction cardboard | 0,13 |

| Foamed rubber | 0,03 |

| Natural rubber | 0,042 |

| Fluorinated rubber | 0,055 |

| Expanded clay concrete | 0,2 |

| Silica brick | 0,15 |

| Hollow brick | 0,44 |

| Silicate brick | 0,81 |

| Solid brick | 0,67 |

| Slag brick | 0,58 |

| Siliceous slabs | 0,07 |

| Sawdust - backfill | 0,095 |

| Dry sawdust | 0,065 |

| PVC | 0,19 |

| Foam concrete | 0,3 |

| Styrofoam | 0,037 |

| Expanded polystyrene PS-B | 0,04 |

| Polyurethane foam sheets | 0,035 |

| Polyurethane foam panels | 0,025 |

| Lightweight foam glass | 0,06 |

| Heavy foam glass | 0,08 |

| Glassine | 0,17 |

| Perlite | 0,05 |

| Perlite-cement slabs | 0,08 |

| Sand | |

| 0% humidity | 0,33 |

| 10% humidity | 0,97 |

| 20% humidity | 1,33 |

| Burnt sandstone | 1,5 |

| Facing tiles | 105 |

| Thermal insulation tiles | 0,036 |

| Polystyrene | 0,082 |

| Foam rubber | 0,04 |

| Cork board | 0,043 |

| Cork sheets are lightweight | 0,035 |

| Cork sheets are heavy | 0,05 |

| Rubber | 0,15 |

| Ruberoid | 0,17 |

| Scots pine, spruce, fir (450...550 kg/cub.m, 15% humidity) | 0,15 |

| Resinous pine (600...750 kg/cub.m, 15% humidity) | 0,23 |

| Glass | 1,15 |

| Glass wool | 0,05 |

| Fiberglass | 0,036 |

| Fiberglass | 0,3 |

| Paper roofing felt | 0,23 |

| Cement boards | 1,92 |

| Cement-sand mortar | 1,2 |

| Cast iron | 56 |

| Granulated slag | 0,15 |

| Boiler slag | 0,29 |

| Cinder concrete | 0,6 |

| Dry plaster | 0,21 |

| Cement plaster | 0,9 |

| Ebonite | 0,16 |

| Expanded ebonite | 0,03 |

| Linden, birch, maple, oak (15% humidity) | 0,15 |

One of the most important indicators of building materials, especially in the Russian climate, is their thermal conductivity, which general view is defined as the ability of a body to exchange heat (that is, distribute heat from a hotter environment to a colder one).

In this case, the colder environment is the street, and the hotter environment is the indoor space (in summer it is often the other way around). Comparative characteristics is given in the table:

The coefficient is calculated as the amount of heat that will pass through a material 1 meter thick in 1 hour when the temperature difference between inside and outside is 1 degree Celsius. Accordingly, the unit of measurement for building materials is W/ (m*oC) - 1 Watt, divided by the product of a meter and a degree.

| Material | Thermal conductivity, W/(m deg) | Heat capacity, J/(kg deg) | Density, kg/m3 |

| Asbestos cement | 27759 | 1510 | 1500-1900 |

| Asbestos cement sheet | 0.41 | 1510 | 1601 |

| Asbozurite | 0.14-0.19 | — | 400-652 |

| Asbomica | 0.13-0.15 | — | 450-625 |

| Asbotekstolit G (GOST 5-78) | — | 1670 | 1500-1710 |

| Asphalt | 0.71 | 1700-2100 | 1100-2111 |

| Asphalt concrete (GOST 9128-84) | 42856 | 1680 | 2110 |

| Asphalt in floors | 0.8 | — | — |

| Acetal (polyacetal, polyformaldehyde) POM | 0.221 | — | 1400 |

| Birch | 0.151 | 1250 | 510-770 |

| Lightweight concrete with natural pumice | 0.15-0.45 | — | 500-1200 |

| Concrete on ash gravel | 0.24-0.47 | 840 | 1000-1400 |

| Concrete on crushed stone | 0.9-1.5 | — | 2200-2500 |

| Concrete on boiler slag | 0.57 | 880 | 1400 |

| Concrete on sand | 0.71 | 710 | 1800-2500 |

| Concrete based on fuel slag | 0.3-0.7 | 840 | 1000-1800 |

| Dense silicate concrete | 0.81 | 880 | 1800 |

| Bitumen perlite | 0.09-0.13 | 1130 | 300-410 |

| Aerated concrete block | 0.15-0.3 | — | 400-800 |

| Porous ceramic block | 0.2 | — | — |

| Light mineral wool | 0.045 | 920 | 50 |

| Heavy mineral wool | 0.055 | 920 | 100-150 |

| foam concrete, gas and foam silicate | 0.08-0.21 | 840 | 300-1000 |

| Gas and foam ash concrete | 0.17-0.29 | 840 | 800-1200 |

| Getinax | 0.230 | 1400 | 1350 |

| Dry molded gypsum | 0.430 | 1050 | 1100-1800 |

| Drywall | 0.12-0.2 | 950 | 500-900 |

| Gypsum perlite solution | 0.140 | — | — |

| Clay | 0.7-0.9 | 750 | 1600-2900 |

| Fireproof clay | 42826 | 800 | 1800 |

| Gravel (filler) | 0.4-0.930 | 850 | 1850 |

| Expanded clay gravel (GOST 9759-83) - backfill | 0.1-0.18 | 840 | 200-800 |

| Shungizite gravel (GOST 19345-83) - backfill | 0.11-0.160 | 840 | 400-800 |

| Granite (cladding) | 42858 | 880 | 2600-3000 |

| Soil 10% water | 27396 | — | — |

| Sandy soil | 42370 | 900 | — |

| The soil is dry | 0.410 | 850 | 1500 |

| Tar | 0.30 | — | 950-1030 |

| Iron | 70-80 | 450 | 7870 |

| Reinforced concrete | 42917 | 840 | 2500 |

| Reinforced concrete | 20090 | 840 | 2400 |

| Wood ash | 0.150 | 750 | 780 |

| Gold | 318 | 129 | 19320 |

| Coal dust | 0.1210 | — | 730 |

| Porous ceramic stone | 0.14-0.1850 | — | 810-840 |

| Corrugated cardboard | 0.06-0.07 | 1150 | 700 |

| Cardboard facing | 0.180 | 2300 | 1000 |

| Waxed cardboard | 0.0750 | — | — |

| Thick cardboard | 0.1-0.230 | 1200 | 600-900 |

| Cork cardboard | 0.0420 | — | 145 |

| Multilayer construction cardboard | 0.130 | 2390 | 650 |

| Thermal insulating cardboard | 0.04-0.06 | — | 500 |

| Natural rubber | 0.180 | 1400 | 910 |

| Solid rubber | 0.160 | — | — |

| Fluorinated rubber | 0.055-0.06 | — | 180 |

| Red cedar | 0.095 | — | 500-570 |

| Expanded clay | 0.16-0.2 | 750 | 800-1000 |

| Lightweight expanded clay concrete | 0.18-0.46 | — | 500-1200 |

| Blast-furnace brick (fire-resistant) | 0.5-0.8 | — | 1000-2000 |

| Diatomaceous brick | 0.8 | — | 500 |

| Insulating brick | 0.14 | — | — |

| Carborundum brick | — | 700 | 1000-1300 |

| Red dense brick | 0.67 | 840-880 | 1700-2100 |

| Red porous brick | 0.440 | — | 1500 |

| Clinker brick | 0.8-1.60 | — | 1800-2000 |

| Silica brick | 0.150 | — | — |

| Facing brick | 0.930 | 880 | 1800 |

| Hollow brick | 0.440 | — | — |

| Silicate brick | 0.5-1.3 | 750-840 | 1000-2200 |

| Silicate brick from those. voids | 0.70 | — | — |

| Slotted silicate brick | 0.40 | — | — |

| Solid brick | 0.670 | — | — |

| Construction brick | 0.23-0.30 | 800 | 800-1500 |

| Treble brick | 0.270 | 710 | 700-1300 |

| Slag brick | 0.580 | — | 1100-1400 |

| Heavy cork sheets | 0.05 | — | 260 |

| Magnesia in the form of segments for pipe insulation | 0.073-0.084 | — | 220-300 |

| Asphalt mastic | 0.70 | — | 2000 |

| Basalt mats, canvases | 0.03-0.04 | — | 25-80 |

| Stitched mineral wool mats | 0.048-0.056 | 840 | 50-125 |

| Nylon | 0.17-0.24 | 1600 | 1300 |

| Wood sawdust | 0.07-0.093 | — | 200-400 |

| Tow | 0.05 | 2300 | 150 |

| Plaster wall panels | 0.29-0.41 | — | 600-900 |

| Paraffin | 0.270 | — | 870-920 |

| Oak parquet | 0.420 | 1100 | 1800 |

| Piece parquet | 0.230 | 880 | 1150 |

| Panel parquet | 0.170 | 880 | 700 |

| Pumice | 0.11-0.16 | — | 400-700 |

| Pumice concrete | 0.19-0.52 | 840 | 800-1600 |

| Foam concrete | 0.12-0.350 | 840 | 300-1250 |

| Foam resopen FRP-1 | 0.041-0.043 | — | 65-110 |

| Polyurethane foam panels | 0.025 | — | — |

| Penosilalcite | 0.122-0.320 | — | 400-1200 |

| Lightweight foam glass | 0.045-0.07 | — | 100..200 |

| Foam glass or gas glass | 0.07-0.11 | 840 | 200-400 |

| Penofol | 0.037-0.039 | — | 44-74 |

| Parchment | 0.071 | — | — |

| Sand 0% moisture | 0.330 | 800 | 1500 |

| Sand 10% moisture | 0.970 | — | — |

| Sand 20% humidity | 12055 | — | — |

| Cork plate | 0.043-0.055 | 1850 | 80-500 |

| Facing tiles, tiles | 42856 | — | 2000 |

| Polyurethane | 0.320 | — | 1200 |

| High Density Polyethylene | 0.35-0.48 | 1900-2300 | 955 |

| Low density polyethylene | 0.25-0.34 | 1700 | 920 |

| Foam rubber | 0.04 | — | 34 |

| Portland cement (mortar) | 0.470 | — | — |

| Pressspan | 0.26-0.22 | — | — |

| Cork granulated | 0.038 | 1800 | 45 |

| Mineral cork based on bitumen | 0.073-0.096 | — | 270-350 |

| Technical plug | 0.037 | 1800 | 50 |

| Cork flooring | 0.078 | — | 540 |

| Shell rock | 0.27-0.63 | 835 | 1000-1800 |

| Gypsum grout mortar | 0.50 | 900 | 1200 |

| Porous rubber | 0.05-0.17 | 2050 | 160-580 |

| Ruberoid (GOST 10923-82) | 0.17 | 1680 | 600 |

| Glass wool | 0.03 | 800 | 155-200 |

| Fiberglass | 0.040 | 840 | 1700-2000 |

| Tufobeton | 0.29-0.64 | 840 | 1200-1800 |

| Ordinary hard coal | 0.24-0.27 | — | 1200-1350 |

| Slag pumice concrete (thermosite concrete) | 0.23-0.52 | 840 | 1000-1800 |

| Gypsum plaster | 0.30 | 840 | 800 |

| Crushed stone from blast furnace slag | 0.12-0.18 | 840 | 400-800 |

| Ecowool | 0.032-0.041 | 2300 | 35-60 |

A comparison of the thermal conductivity of building materials, as well as their density and vapor permeability is presented in the table.

The most important ones are highlighted in bold. efficient materials, used in the construction of houses.

Below is a visual diagram from which it is easy to see how thick a wall made of different materials should be in order for it to retain the same amount of heat.

Obviously, in this indicator, artificial materials (for example, polystyrene foam) have an advantage.

Approximately the same picture can be seen if you make a diagram of the building materials that are most often used in work.

Wherein great importance have conditions environment. Below is a table of the thermal conductivity of building materials that are in use:

- V normal conditions(A);

- in conditions high humidity(B);

- in arid climates.

Data taken based on relevant building codes and rules (SNiP II-3-79), as well as from open Internet sources (web pages of manufacturers of relevant materials). If there is no data on specific operating conditions, then the field in the table is not filled in.

The higher the indicator, the more heat it transmits, all other things being equal. So, for some types of polystyrene foam this figure is 0.031, and for polyurethane foam - 0.041. On the other hand, concrete has a coefficient that is an order of magnitude higher - 1.51, therefore, it transmits heat much better than artificial materials.

Comparative heat losses through different surfaces of the house can be seen in the diagram (100% - total losses).

Obviously, most of it comes from the walls, so finishing this part of the room is the most important task, especially in northern climates.

Video for reference

The use of materials with low thermal conductivity in house insulation

Today, artificial materials are mainly used - polystyrene foam, mineral wool, polyurethane foam, polystyrene foam and others. They are very effective, affordable and fairly easy to install, without requiring any special skills.

- when constructing walls (less thickness is required, since the main burden of heat conservation is borne by thermal insulation materials);

- when maintaining the house (less resources are spent on heating).

Styrofoam

This is one of the leaders in its category, which is widely used in insulating walls both outside and inside. The coefficient is approximately 0.052-0.055 W/(oC*m).

How to choose quality insulation

When choosing a specific sample, it is important to pay attention to the labeling - it contains all the basic information that affects the properties.

For example, PSB-S-15 means the following:

Mineral wool

Another fairly common insulation material that is used both indoors and outdoors. exterior decoration premises is mineral wool.

The material is quite durable, inexpensive and easy to install. At the same time, unlike foam plastic, it absorbs moisture well, so when using it it is necessary to use waterproofing materials, which increases the cost of installation work.