The process of sharpening a knife or any tool does not require any outstanding skills or knowledge of special movements. In most cases, sharpening a knife, even the most original and expensive one, can be done with ordinary abrasive stones or sharpening devices. But under one condition - you must try to follow the recommendations of specialists involved in sharpening tools in industrial conditions.

How to sharpen a knife

There may be several answers to the question of how to sharpen a knife:

- You can restore the tool using a sharpening stone or a set of triangular files with a fine notch;

- Use a knife sharpener. The main difference between this method and the previous version is that the support under the blade allows you to maintain a stable sharpening angle of the edge;

- Use a knife sharpening machine.

For your information! Despite what hand sharpening enthusiasts may say, a properly configured automatic or miniature machine will cope with the formation of edge angles much better than a hand whetstone.

For ordinary people, sharpening knife edges is everyday business, and if there is a choice, use a DIY knife sharpening machine or sharpen the blade by hand cutting edge within a few hours, then, apparently, common sense will choose sharpening machine.

How to get a sharp edge on a kitchen knife

The movement and tilt of the blade relative to the block is not as obvious as it might seem at first glance. To correctly understand the sharpening technique, you can use the video about sharpening knives:

For your information! Modern knives are made from a wide range of carbon and alloy steels. Hardened forged steel must be sharpened with an abrasive stone, and relatively tough stainless steel only with a triangular file.

Blades made of soft and tough steels with low chromium and carbon content can be sharpened with a file, while at the same time they very quickly clog the surface of the abrasive stone. Flexible forged blades must be fixed with a stop and sharpened with a block using sliding movements. Regular use of a sharpening stone kitchen knives leads to greasy surface, which has to be restored by sanding.

The old device for sharpening forged knives was made in the form of two wedge-shaped bars made of bog oak. The bars were placed on both sides of the blade so that the cutting edge remained free, the “sandwich” was tied with twine and sharpened with an ordinary whetstone to a razor sharpness. Wedges made of hard wood made it possible to correctly guide the block and obtain the required sharpening angle.

According to the recommendations given, manual sharpening of planer knives is performed. Fine-grained sandpaper is glued onto thick glass, but the beveled part of the cutting edge is placed on the surface of the abrasive and sharpened in a circular motion.

Sharpening a ceramic knife is more difficult; you can manually trim the cutting edge with a diamond-coated needle file, or use a special grinding paste.

Homemade knife sharpening options

The simplest device for sharpening knives is shown in the diagram. To make it, you will need a block of hard wood, the upper plane of which is sharpened at an angle to form the cutting edge. This solution helps to maintain the correct edge processing angle. To make sharpening the blade more convenient, you can screw a pair of self-tapping screws to fix the blade into the plane of the block.

To sharpen planing knives, you can make the sharpener attachment shown in the photo with your own hands. This solution simplifies the process and allows you to sharpen the blade as sharply as possible, but the lack of mechanization requires a certain skill and dexterity from the master.

Devices and machines for straightening and sharpening knives

Sharpening knives is certainly a creative activity that requires a lot of patience and skill. But is it worth spending time and energy on solving a task that can be successfully handled by a specially designed machine or device for sharpening knives? If for knives, household tools, for example, planing devices, kitchen or cutting blades, you can try to restore the cutting edge of the blade with your own hands, then for industrial volumes even sharpening devices will not help. You will need a powerful and productive machine.

Machines for sharpening the blades of cutting knives

The highest form of a sharp knife blade are non-rare models with chrome-plated blades and handles made of rare wood. These are more like museum exhibits or cheap imitation of them. An example of the sharpness of a blade is considered to be a carving or boning knife, which is used to cut raw meat and skins for 12 hours a day. It is under such conditions that the edge of a forged knife made of high-quality steel becomes dull unusually quickly.

For small volumes of cutting work, knife blades can be sharpened on simple machines with automatic control of the cutting edge angle.

For cutting areas of meat processing enterprises, professional equipment KNECHT USK 160 is most often used. high degree versatility, which allows you to sharpen the entire range of cutting tools, from fillet blades to cutting scissors.

Machines for sharpening cutting elements of carpentry tools

Sharpening knives for woodworking machines requires the mandatory use of specialized machine equipment. If you can sharpen a relatively short blade of a home knife or hand plane manually using a simple device, then the long and sharp blades of jointers and planers must be sharpened using a mechanical feed drive for the sharpening tool.

If you try to sharpen a tool with your own hands on a sharpening cup without support and guide slides, areas with different sharpening angles will form on the cutting edge. When processing wood, this leads to the formation of an uneven wavy surface of the board or solid wood.

Small flat knife blades can be sharpened to a simple machine vertical type.

Circular saws are usually sharpened on machines equipped with a divider and a rotary table.

Universal sharpening machines

In small carpentry shops, woodworking areas, and repair shops, universal sharpening machines are used that are capable of sharpening a very wide range of cutting tools, including sharpening guillotine knives.

As an example, we can cite the desktop model of the VZ-319 machine. Thanks to the rigid bed and correctly selected gear ratios of the mechanical drive, the unit can sharpen almost any tool, from plane blades to cylindrical cutters.

Conclusion

Sharpening knives has long gone beyond the scope of craftsmanship into the category of an ordinary mechanical operation. A large number of All kinds of machines and devices, tabletop machines and automatic machines are capable of performing difficult work within a few minutes. A high-quality sharpener purchased once in your life can last for several decades, eliminating the hassle of sharpening knife blades.

Having a sharpening machine at home solves many problems with sharpening metal equipment, but, alas, the cost of such a machine is quite high. We'll look at how to design a homemade sharpening machine below.

Functional features of operation and structure of the sharpening machine

A sharpening machine is used to sharpen a variety of steel products. This unit consists of a frame to which an electric motor is attached. The engine is mounted with an axis shift of 1.5°. A unit with a grinding device is attached to the motor shaft. If you move the unit manually, it is possible to sharpen the part in the horizontal and vertical direction.

The guide, which is located on two column parts, carries out horizontal feeding. It moves thanks to the presence of a transmission worm type, which is located on the bed. A dial device is attached to the end part of the worm shaft, which performs direct movement of the grinding wheel.

Longitudinal feeding should be done manually, by moving the part that can be sharpened. The mandrel is another part of the sharpening machine that is attached to the stands. The nodal holder is fixed thanks to the presence of clamp-screws.

The holder contains a handle that allows the part to pass through the machine. To carry out circular sharpening of the part, there is a hole to which an attachment is attached that allows you to sharpen knives. On the holding device there is a component at hand, with the help of which the tool is sharpened.

Depending on the type of work being done on a sharpening machine, there are several fundamental differences in the way tools are sharpened. Highlight:

- sharpening using a holding device;

- radius sharpening option with an attachment;

- sharpening with a tool.

The first option allows you to process a completely flat blade with a straight edge. It includes availability:

- manual plane,

- jointers,

- metal planer plates,

- chopped,

- chisel

Before starting work, you should pay attention to the location of the slider. It should be installed in the extreme left position. Next, the part is secured using a U-shaped bracket, fixation and clamping screws. The edge that chamfers must be parallel to the working end of the grinding wheel. The gap between these parts should be 0.1-0.2 cm.

Then the device is turned on and sharpening is performed. The person working with the part must ensure that it comes into easy contact with the grinding wheel. Wherein left hand is responsible for the rotation of the transverse gear, and the right one moves the part longitudinally. The movement of the part occurs exclusively along the working end of the grinding wheel.

During radius-type sharpening, an attachment part is used to ensure that an extraordinary sharpening is obtained on a tool with cutting-type edges.

If sharpening is done using an attachment, the clamping brackets and fixing screws are disconnected. The attachment axis is installed on the center of the machine and then secured with a clamp screw.

If the attachment rotates easily, it means it is installed correctly. Next, you need to fix the holder and move the slider to the middle of the grinding machine.

Advantages and scope of use of the sharpening machine

Electromechanical grinding machines have many advantages compared to manual devices:

1. The ability to carry out many operations on sharpening various tools independently, without the involvement of a specialist.

2. Long service life allows you to use the sharpening machine for 10-15 years.

3. Mechanization of the sharpening process saves time and makes the process easier.

4. The ease of use of the sharpening machine allows even a non-professional to perform a variety of sharpening and grinding operations on metal parts.

5. Another advantage of this device is the ability to self-made: This will save you a lot of money on the purchase of this device.

6. Universal type sharpening machines are characterized by high productivity and operating efficiency.

There are sharpening machines that can sharpen only one tool, and universal sharpening machines that are suitable for sharpening almost any equipment.

Sharpening machines are capable of sharpening a knife, chainsaw, drills, cutters, cutters, cutters, broaches. They also carry out internal and external grinding of metal surfaces.

Sharpening of any tool is required almost anywhere, and therefore the scope of use of the sharpening machine is quite wide. They are used both in the private sphere, in garages, service stations, workshops and in large industrial installations.

Main types of sharpening machines

In accordance with the method and subject of sharpening, machines are distinguished:

- universal type,

- specialized type.

A universal sharpening machine allows you to process parts of different types. They are equipped with regular and special devices that secure and secure a variety of tools. Such machines are capable of grinding: reamers, shaped cutters, cutters, drills, dies, etc.

A specialized sharpening machine differs from a universal one in its ability to sharpen parts of only one type. They are highly productive because they do not require constant replacement. structural elements. Specialized machines are characterized by more precise quality of processing of parts. Such machines are used in enterprises that grind parts or spare parts, or in the case when sharpening at universal machine is inaccurate.

Universal type machines do an excellent job of sharpening blade equipment such as cutters, cutters and reamers. They provide the ability to process gear cutting heads, cutters or hobs.

Specialized sharpening machines are divided into machines:

- for chainsaws,

- for drills,

- for knives, etc.

Sharpening machines for chainsaws are divided into two types: electric and manual. Sharpening on a manual machine involves precise sharpening of the chain. It is possible to fix the position of the file, so all the teeth are sharp and have the same size.

Workshops specializing in sharpening chainsaws use electrical equipment. It includes a sharpening disc that can be adjusted to precisely indicate the angle for sharpening.

DIY universal sharpening machine

To manufacture a sharpening machine, you will need an electric motor whose power does not exceed 1 kW, two pulleys, and bearings with a shaft.

These parts are mounted on a frame, which is most easily made from steel angles.

For the tool rest, you need to build a rotating bar that adjusts the inclination of the part in relation to the grinding wheel.

During the sharpening process, the part should be positioned so that it has minimal contact with the wheel. Gradually bring her closer.

The grinding machine design is based on the correct calculations for installing the grinding wheel and tool rest.

1. Use the protective cover to close the gap circle.

2. When working with the machine, use safety glasses to protect yourself from getting splinters in your eyes.

3. The maximum distance between the plate and the grinding wheel is 0.3cm.

4. The length of the flanges responsible for the clamp must be no less than a quarter of the diameter of the circle.

5. A paronite gasket should be installed in the nut-flange space; it will ensure tightening of the nut on the shaft section.

DIY drill sharpening machine

To save money on buying a drill sharpening machine, try making one yourself.

To do this you will need:

- toggle switch,

- grinding wheel,

- plugs,

- powerful electric motor,

- stands,

- electrical wires,

To protect yourself while working, it is recommended to install the machine on a frame that will be closed, only the grinding wheel and axis will be visible from the outside.

This unit will operate from the mains. The best place to install such a machine is a steel table.

Sharpening machine instructions:

1. Place the grain disk onto the motor shaft. If the diameter of the disk does not match the diameter of the shaft, use a washer.

2. Then secure them with a fastening nut or use a special attachment that will ensure reliable sharpening of the drill.

3. If the shaft size is smaller than the disk size, a bushing is required. It is attached to the shaft with a bolt into a pre-prepared hole.

Tip: When choosing an electric motor excellent option The device will be made from an old washing machine.

4. The next step involves connecting the motor to the wires and socket. It is possible to use wires from old unnecessary electrical appliances.

5. Connect the wire to starting device. It must have three open contacts. Connect them in such a way that you can easily turn the machine on and off using a button.

6. To protect the electric motor from dirt and dust, a protective box should be made for it.

Knife sharpening machine: manufacturing instructions

Let's consider several options for making homemade sharpening machines with which you can sharpen a knife.

The first option is a manual machine. To make it you will need:

- wooden planks or boards,

- screws,

- whetstone for sharpening.

Take two wooden squares and fasten them with screws, and insert a block between them. It must fit securely into the device. The angle size is calculated in relation to the required sharpening angle of the knife.

The main disadvantage of such a device is that the angle of the bar cannot be adjusted. The entire structure needs to be disassembled.

Another option consists of a threaded washer that holds the block in a secure position. Use heat shrink tubing to cover the threads.

Use the two paper clips to secure the stand to the desired height. Thus, holding the beam in your hand, select the required level of inclination and sharpen it.

Another version of a manual machine will allow you to sharpen not only knives, but also chisels and planes. Secure the device to be sharpened into the block. The choice of sharpening angle depends on the angle at which the block will be positioned in relation to the tool. To ensure ease of sharpening and protect the surface from damage, place a wooden board or glass under this device.

How to make a machine for sharpening knives with your own hands at home and what materials/tools will help in this matter?

Knives in everyday life should always be sharp enough to comfortably perform their functions. When cooking and cutting food, they constantly become dull, and as a result, they need to be sharpened.

To carry out this work, many different machines and devices have been invented, ranging from a simple sharpening stone to complex electric sharpening machines. Using a simple beam is quite inconvenient and takes a long period of time. Exist manual machines to carry out this work.

Manual knife sharpeners

Sharpening machines from the American company Lansky have slightly improved the usual sharpening with a bar. Using such a device, you can quite accurately adjust the angle of work with the blade, from 17 to 30 degrees.

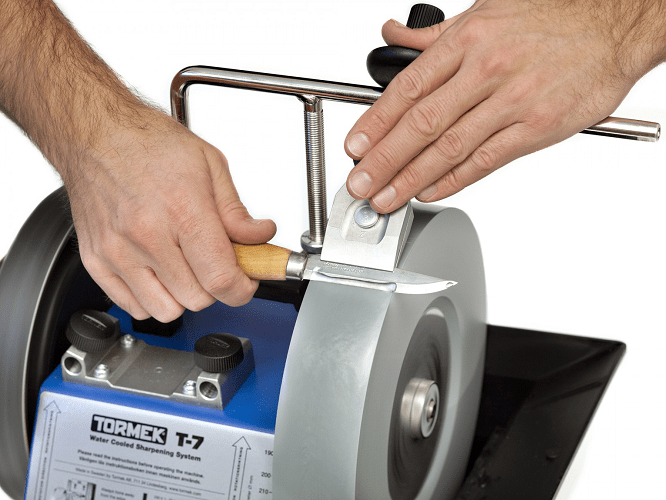

Lansky sharpening device during operation

Any craftsman can make a similar machine for sharpening knives with his own hands due to the simplicity of its design, as demonstrated in the video below.

Locking blade machines

These devices allow you to sharpen a knife much faster because they allow you to apply more effort. Moreover, due to the presence of a rigid stop in the form of a table, the efficiency also increases several times.

SpitJack knife sharpening machine

As can be seen in the figure, in machines of this type the sharpening bar moves along the stationary blade at a set angle. The sharpening angle is adjusted by changing the height of the bar attachment. Among the domestic analogues of such machines, we can mention the machine produced by the Ermak company.

Ermak sharpening device

Machines with fixed sharpening surfaces

In devices of this type, there is no way to adjust the sharpening angle yourself. Most often, such a device already has several different angles for operation. When using such machines, you simply need to move the blade along the sharpening recess.

This recess consists of two planes, one or two of which are the sharpening beam. So, in order to sharpen a kitchen appliance, you just need to run the knife along the sharpening surface several times.

Mechanical sharpener Chief's Choice

Electrical devices for pointing knives

We can also mention professional cutlery, which is used by most chefs and requires only a few seconds for the knife to become as sharp as possible again. These devices have an electric motor that rotates the sharpening blades.

Such blades are often made from diamond abrasives, and the engine power does not exceed 100-150 kW. Although, of course, there are more powerful machines for sharpening blades that are used in production.

Making a sharpening device with your own hands

To make a machine for sharpening knives with your own hands, you will need: a piece of laminate, wooden slats, sandpaper, and two bots with lambs. Instead of laminate, you can use chipboard or plywood.

To make a knife holder, you need to cut off part of the laminate. To prevent the block from touching the holder when sharpening, you need to clean off its edge at an angle using sandpaper.

- We mark and cut off the upper part of the vertical stand on which the block will rest when sharpening. We choose an angle half as large as the one at which the knife will be sharpened; in our case it is 30°. For kitchen appliances it is better to use 10–15°. A total of 2 such parts will be needed.

- To correctly calculate the length of the base and the height of the racks, you need to roughly draw up the structure and make markings. It should be taken into account that the height will be affected by further installation of the transverse support. After that, we cut off all the parts and clean their edges.

- Now we mark and simultaneously drill holes in the base and the pressure plate for the bolts that secure the knife blade. When marking, it is important to maintain the distance of the holes from the edge of the base. This is necessary to ensure installation versatility since the knives have different blade widths. We fasten the pressure plate with bolts.

- Vertical posts can be secured with screws, but given that the load on them is small, it is better to use hot glue. In the same way we attach the horizontal crossbar. At this stage, the sharpener is already ready, all that remains is to make the block.

- To make a bar, cut a strip of suitable length. On one edge we glue sandpaper with the required abrasive size, in our case it is P1200. To improve the result, you can make several bars with different grain sizes. The range P600 – P2000 is considered more optimal. To protect your hands from cuts, it is advisable to screw the handle on the top side of the rail.

- As a result, we get a functional and practical machine for sharpening kitchen knives. When working, it rests with bolts on the edge of the table, which increases the comfort of use.

Video: how to make a knife sharpener from a piece of laminate?

Currently, there are several types: a machine for sharpening knives, a machine for a hairdressing machine, and others. This article talks about how to make a machine for sharpening knives at home: detailed drawings with dimensions, photos and videos (2-3 videos) are presented.

Often, when sharpening knives at home, household members use abrasive whetstones. However, in order to use them in practice, you need the necessary skills and experience working with them. After all, if the knife is sharpened at the wrong angle, the blade remains dull.

Layout of the block to the blade.

Before actually manufacturing the machine, you need to listen to the advice of sharpeners.

When sharpening a knife, the master performs the following actions:

Defines the angle between work area blades and whetstone. Moreover, for each model the angles are different;

The knife is located at an angle of 90 degrees to the direction of the block. The grooves that are formed when the razor blade of the knife rubs against the block should be at 90 degrees to the knife line. The angle in such a situation is equal to half the sharpening;

Typically the angle is 25 degrees;

The mechanic begins processing from the beginning of the foot blade;

When adjusting the sharpening angle, the master paints over part of the foot blade with any marker. As a result, the mechanic directly controls the work area.

As a rule, after sharpening the working blade has non-uniform deformations. Therefore, when processing independently, the “point of reference” should not be the sharp part of the knife.

Choosing whetstones for sharpening a knife

The main indicator of a block is its grain size.

The whetstone is the main component that makes the blade thin and sharp. As a result, before choosing a design, you need to select the necessary blocks.

When sharpening knives on their own, household members use these types of whetstones

which have a high grain size. Using such bars, the shape of the leg blade is corrected.

having medium grain size. With the help of such bars, the mechanic removes the grooves that are formed during the initial processing of the knife

whetstone, which is covered with GOM paste. In such a situation, the mechanic polishes the blade.

When processing knives for the kitchen, you can use two types - with medium and high grain. And also in this case it is necessary to use a touchstone.

Base

When making a sharpening machine at home, you can use various parts. In particular, you can use laminated box plywood 12 mm thick, which was previously used to create radio equipment housings.

When constructing a machine at home, a household member performs the following actions:

Selects a base for such an installation, which must weigh at least 5 kg. Otherwise, it will be impossible to sharpen chopping devices and tools on the machine. Therefore, in the manufacture of such equipment, the tenant uses various steel angles measuring 20x20 mm;

Next, 2 parts are cut out of plywood with a jigsaw, which have a trapezoidal shape, the base is 170 by 60 mm, and the height is 230 mm. When cutting, the mechanic makes an allowance of 0.7 mm for sharpening the ends: they end up straight and fit according to the markings;

Installs 3 parts between the inclined walls on the sides - an inclined surface made of plywood with dimensions of 230 x 150 mm.

In such a situation, the trapezoidal sides are located laterally on a rectangular surface.

The result is a base - a wedge. In such a situation, a protrusion of an inclined surface measuring 40 mm is formed in the front part;

Then, along the side wall ends, the mechanic marks 2 lines with a thicknesser. At the same time, it retreats by half the thickness of the plywood;

Drills the ends of the inclined surface and connects the base parts for a while;

At the back of the structure, the mechanic connects the side walls using a 60x60 mm block, which is attached to the end with two screws on both sides; - makes a 10 mm gap in the block.

In such a situation, it retreats 50 mm from the center - 25 mm from the edge. To maintain a vertical position, first drill with a thin drill from 2 edges, and then expand;

Then, at the top and bottom, two threaded fittings are screwed into the slot, and in the fittings - a 10 mm pin, the length of which is 250 mm.

If the threads do not match the studs, the lower fitting is adjusted.

Tool support device

When making a handhold device, the following steps are performed:

Removes the flat inclined part from the base, modifies it and installs a fixation device on it, as well as the clamp of the device used;

Measures 40 mm from the edge in front and at this mark, using a garden hacksaw, cuts out a groove, the depth of which is 2 mm;

Using a shoemaker's knife, chip off the top 2 veneer layers from the end of the board. The result is a sample into which the mechanic inserts a 2 mm steel plate at the same level as the general surface;

The tool rest consists of 2 steel strips measuring 170x60 mm and 150x40 mm. The machine operator connects them along the large end, which has equal edge indentations, and makes 3 through slots of 6 mm.

Using bolts, tighten the planks along the cracks made. In such a situation, the machine operator leaves the bolt heads on the side of the large top plate;

Then he removes metal defects of the weld in the form of beads and grinds the plate to give it a smooth surface;

Applies a small striker plate to the edge recess, moves the slots with a drill and secures the support with bolts.

Fixation device

The second important part of the tool rest is the clamping bar. It can be made from 2 parts.

L-shaped plank measuring 150x180 mm, the width of the shelves is 50 mm (top);

A rectangle-shaped strike plate measuring 50x100 mm (bottom).

When making a clamping bar, the machine operator performs the following actions:

Places the bottom bar on the far edge of the top bar;

Makes 2 holes in the center and retreats 25 mm from the edges of the part, connects the parts through the holes with two 8 mm bolts;

Screws in 8 mm bolts on 2 sides. In such a situation, the head of the nearest bolt is located near the top bar;

Welds the bolt heads to the plates and grinds them in advance until roundness is formed;

Yes, the inclined board retreats 40 mm from the edge and draws a line with a thicknesser;

Makes one 8 mm 25 mm gap at the bottom and top edges;

Using markings, he connects the edges of the slots and uses a jigsaw to make a cut with an allowance. Use a file to expand the groove to a width of 8.5 mm;

It fastens the planks using a groove that is in the board; the top bolt is tightened with a nut and thus firmly fastens the plank.

Then tightens connection 2 with nut;

When pressing the bottom bar (in the niche of the base), screw a wing nut onto the second bolt.

Sharpening angle control

When adjusting the sharpening angle, the mechanic performs the following actions:

Throw a large washer onto the pin, which is located in the block of the machine base, and tighten the nut.

The rod does not rotate in the foot; the block for adjusting the sharpening angle is made from a small carbolite block, the dimensions of which are 20x40x80 mm.

15 mm from the block edge, drill a 20 mm end on both sides, widen the gap to 9 mm, then make a thread inside;

He steps back 50 mm from the axis of the new slot and drills another one in the flat part of the workpiece - 90 degrees to the previous one. Such a slot has a diameter of 14 mm. In such a situation, the mechanic strongly flares the hole using a round rasp;

Screws the block onto the pin - sets the desired height of the eye without using fixing screws;

Secures the block on both sides with M10 hex nuts.

Using replaceable blocks and making a carriage

When making a sharpening carriage, the machine operator performs the following actions:

Welds 30 cm M10 threaded rods with a smooth rod whose thickness is 10 mm;

Uses 2 solid bars 50x80 mm and the thickness is 20 mm. In all blocks, in the center and on top, 20 mm is retreated from the edge, and then a gap is made 10 mm wide;

Screws a wing nut onto the rod, then a large washer and 2 bars, then a nut and washer;

Clamps rectangular sharpening stones between the stones or makes several replaceable sharpening stones.

As a timber base, the machine operator uses a rectangular tube from a profile or a piece of cornice, the width of which is 50 mm;

Sands the flat machine part and cleans it of grease using glue “ Super Moment» glues strips of sandpaper with a grain size of up to 1200 grit.

The sandpaper should have a fabric base, and on 1 of the blocks you need to glue a strip of suede to apply polish to the blades.

Simple homemade machine

The most common version of the machine design is 2 pairs of wooden slats, which are fastened together with screws. The machine operator installs a block between such parts.

The main reason for the popularity of usemanual homemade sharpening machine various knives- this is its stability. During operation, the machine structure does not move in any way on the workbench.

When fixing the block, the mechanic uses support strips that are located between the wooden elements.

However, such homemade machine has the following disadvantages:

The master positions the blade to the stone manually. When working for a long time, it is difficult to keep track of the sharpening angle;

When making such an installation, it is necessary to use a fixing unit. The machine structure must be stable, so it must be firmly mounted on the workbench;

During the work, the ties loosen and the location of the block changes.

Another advantage of such a scheme is ease of manufacture. This machine design is most often used when sharpening knives for jointers and for the kitchen.

Wood slats can be of different thicknesses. When making a simple sharpening machine yourself, you can use various available components.

When first studying all the nuances of manufacturing, you need to watch thematic videos that describe in detail how to make a machine at home.

Every housewife sooner or later begins to get dull knives with which she cuts bread, vegetables or cuts meat. Using a dull knife is not only inconvenient, but also unsafe. It can fall off the product being cut at any time and cause injury. Therefore, the tool should be periodically sharpened using a special device for sharpening knives.

A wide range of such sharpening devices are offered in stores. But for one reason or another, they do not always suit the consumer. In this case, you can make a device for sharpening knives with your own hands, having previously studied the types of sharpening stones, the features of the tool and the proposed drawings.

Sharpening knives - necessary conditions

For efficient and long-term operation of a knife, the most important factor when sharpening it is the angle between the edges of the blade. During the sharpening process, it is necessary to restore the previously specified angle, which will fully comply with technological standards and quickly, freely and efficiently cut the material.

Each blade has its own optimal angle:

- for a razor and scalpel, the sharpening angle should be 10–15 degrees;

- knives for cutting bread, fruits and vegetables are sharpened at an angle of 15–20 degrees;

- multifunctional knives for various products are processed at an angle of 20–25 degrees;

- hunting and camping knives - at an angle of 25–30 degrees;

- knives for cutting hard materials - 30–40 degrees.

Without a special device, it is difficult to sharpen the blade at the desired angle. Holding the knife with your hands, it is quite difficult to ensure the required angle of inclination of the cutting tool. To facilitate this process, there are special devices that you can make with your own hands. Their designs are quite simple, and the manufacturing itself does not take much time.

DIY knife sharpeners

There are many types of knife sharpeners, from which you can choose the one that best suits your needs.

There are many types of knife sharpeners, from which you can choose the one that best suits your needs.

All devices consist of two parts:

- a block of abrasive material;

- stop for attaching the knife.

You can use ready-made special stones as a bar or make it yourself.

Sharpening stones - types and manufacture

There are several types of stones on sale:

Water tools. When working with them, water is used, which saves the surface of the stone.

Oil stone resembles water stone in structure and shape, but its surface is the most oily.

Natural instruments are made from natural stones that undergo industrial processing.

Artificial stones are made from non-natural components.

Rubber tools can also be found on sale, but they are not very convenient to work with.

To make your own abrasive bar, you can use small rectangular glass plates with a thickness of 4–5 millimeters. Sandpaper of different grits should be glued to the surface of the plates using double-sided tape. The cost of such bars will be quite small, and the sandpaper can be replaced at any time.

However, when using a glass block, be sure to tighten the nuts very carefully, otherwise the glass may crack. In addition, no water is used when using it, so the abrasive wears out quickly. For the same reason, when sharpening knives, you should avoid rapid movements, which can lead to overheating of the material, and, therefore, to the loss of the properties of the blade.

Device for sharpening from wooden blocks

It is enough to simply make a sharpening tool from two wooden and two abrasive bars, which should be the same size.

For greater stability of the sharpening device, it is recommended to attach a piece of rubber to its lower surface.

Do-it-yourself sharpener from mounting corners

The basis for this device is a Lansky sharpener, drawings of which can be easily found on the Internet.

- metal plates measuring 4x11 centimeters;

- standard aluminum corners;

- metal rods about 15 centimeters long;

- set of nuts and bolts;

- grinder with a vice or file;

- needle file

Instead of a sharpening machine, you can use a file, since this tool is only needed for grinding off sharp corners and cleaning the metal cutting areas.

Stages of making a sharpener:

- According to the drawing, markings are made for future holes in the plates.

- The holes are drilled and threaded.

- Using a file, all sharp corners and edges are rounded. This will allow you to comfortably use the made knife.

- Holes are made in the corner in accordance with the drawing.

- The hole for the spoke support is expanded using a needle file.

- The holes for the studs are threaded.

- The rods are inserted into the outer holes and secured with nuts of the appropriate diameter (M6).

- An M8 bolt is screwed into the wider hole, the length of which should be about 14 centimeters. A wing nut must first be screwed onto it, on top of which two ordinary nuts are screwed. The bolt in the structure will be used as a support post.

- Bolts are attached to the remaining holes, with which the knife will be clamped.

- Nuts are screwed onto the ends of the rods, a corner is threaded, which is fixed with the help of nuts. By lowering or raising the rods, you can adjust the sharpening angle.

- A thin metal rod in the shape of the letter L, a rod with an M6 thread, two holders and a wing nut are used to assemble a device that will hold the sharpening stone. The outermost holder must have a through hole for the knitting needle.

This knife sharpening device has a fairly wide range of pressing angle degrees and is most convenient to use.

Massive sharpener with stand

With your own hands, you can imitate a knife sharpening device from Apex, the drawings of which are easy to find on the Internet. Such a knife is presented in the form of a stand, on which a platform is installed at an angle, and on the side there is a support for the end of the nozzle in the form of a rod. This is a very convenient device with which you can sharpen any cutting tools.

Required materials and tools:

Stages of work:

- Three blanks are cut from a sheet of chipboard. Their dimensions should be: 30x8 cm; 7x8 cm; 37x12 cm.

- On a workpiece measuring 30x8 cm, measure 6 centimeters from the edge on the long side and drill a hole.

- From a block with a cross-section of 2x4 centimeters, a section 8 centimeters long is sawn off, in which two through holes are drilled perpendicular to each other. The first should be three centimeters from the edge, and the second three centimeters from the first.

- A recess one centimeter thick is cut from the edge of the block to the hole.

- A slot is drilled along the middle of the plexiglass.

- Chipboard blanks in the corners large sizes holes are drilled for the legs.

- A small piece of chipboard is placed perpendicularly four centimeters from the edge of the workpiece and secured with two self-tapping screws.

- A medium-sized workpiece is placed on top and also secured with two self-tapping screws.

- For the magnet, a shallow depression is drilled at the very edge of the highest point of a medium-sized part.

- The magnet is inserted inside and fixed with self-tapping screws.

- A piece of plexiglass is placed on the same board. A bolt is inserted through the slot and hole, which is screwed down with a nut at the bottom.

- A hole is drilled on the free edge of a large blank for an iron rod.

- The rod is fixed using two nuts: a wing nut and a regular one.

- A block is screwed onto the rod, into the hole of which a bolt screwed from the outside with a nut is inserted.

- A device for clamping a knife is assembled from a cut of a metal rod, two clamps and four nuts with washers.

- The legs are screwed to the finished product.

The sharpening angle on such a device is adjusted using a bar and a wing, which fixes the part at the desired height.

Each of the described devices has its own advantages and disadvantages. When choosing the appropriate option, you need to proceed from your needs and skills in such work that you will need to do with your own hands.

stanok.guru

DIY knife sharpening device

Every man, and sometimes even a woman, regularly faces the need to sharpen a knife. Every knife, regardless of quality, can become dull over time, so it requires careful care. Found on store shelves big choice sharpeners and sharpening stones, so you won’t have to make a choice special labor.

Types of sharpening stones

There are several types of stones that are used for sharpening knives:

- Oil-based - such stones involve the use of oil on the surface, which saves material consumption.

- Water stones - have the same principle of operation, but water is used to work with them.

- Natural stones are natural materials that have been industrially processed.

- Artificial stones, accordingly, are made from a non-natural component.

- Rubber stones, such material is rare, as they are not convenient to work with.

Some features of knife sharpening

Each knife has its own sharpening feature.

For example, a Japanese knife, for self-sharpening, requires the attention of an experienced craftsman, since Japanese steel is very fragile. Manufacturers recommend using several types of Japanese water stones with different grain sizes for sharpening.

For housewives, it is easier and more convenient to use a special sharpener to sharpen a kitchen knife. However, using several stones will keep the knife sharp for a longer time, which is especially appreciated. Although this will take more time and effort, it will extend the life of the tool.

Conditions for proper sharpening of knives

For correct sharpening When using a knife, it is necessary to create conditions under which the knife will remain sharp for several months. For such sharpening, choosing the right angle will help. There is a rule that determines the correct operating principle - a smaller angle for sharpening a knife will create less strength of the cutting edge. That is, it should be remembered that the sharper the knife is immediately sharpened, the faster the time will come for re-sharpening, and the more difficult it will be to bring the knife to its original working condition.

Why do you need sharpening?

The main point of sharpening knives is to restore the sharpness of the blade itself. Why is it necessary to maintain the correct angle when sharpening. Or rather, restoration of the previously specified angle, which must comply with technological standards. To check the sharpness of a knife, it is necessary to cut the material for which it is intended; if the knife cuts it without problems, then the technique has been followed correctly.

Problems that may arise when sharpening

Without a doubt, to select the appropriate angle, experience is required, without which it is quite difficult to cope with this task. Especially without necessary equipment, since holding the knife with your hands makes it difficult to sharpen it evenly on both sides. To eliminate the problem, it is recommended to build a homemade knife sharpening machine, which is easy to make at home. After all, the existing devices are quite simple in design and are not distinguished by their complexity.

How can you sharpen a knife at home?

There are situations when you need to sharpen a knife very quickly at home; for such purposes you can use the following available materials:

- wooden block;

- hacksaw;

- sandpaper;

- file;

- ceramic plate;

- chisel and some others.

Particularly sophisticated village men can generally sharpen a knife on a foundation made of a solution of cement and sand. However, it is not recommended to follow this example, but to use in practice the most proven methods that are suitable for quick sharpening.

The most the best way there will be production homemade device, since it is effective and very convenient, and besides, it will differ little from the factory one.

What are the drawings for?

Of course, purchasing a ready-made knife sharpener is much easier, and they are not so expensive. Still, most home-conscious owners prefer to do everything with their own hands, this is pleasant and you can be confident in the quality of workmanship. After all, they are used only natural materials. To make the manufacturing process enjoyable and simple, you need to prepare a plan and follow it.

- To begin with, it is manufactured or purchased finished drawing for clamping jaws. When making a drawing, it is necessary to pay attention Special attention the smallest details and think through and draw the entire structure.

- The next step will be to draw a drawing of the right and left stops, for strength assembled structure.

- Make a drawing for a guide, which has its own subtleties.

Guide drawing

All you need for a guide that will fit perfectly is the following:

- A spool with an M6 thread, which must be sawed off using a hacksaw so that it is 16 cm long. The main thing is to ensure that there are no burrs so that they do not slow down the sharpening process itself.

- Also, electrodes with a soft and elastic cylinder can be useful in work; they must be bent into the letter “g” using pliers. The main thing during the work is not to forget to periodically look at the drawing of the product.

- Metal scraps are useful for using clamps; they need to be cut and holes installed using drilling machine. A hand tap will help in marking the threads. And in order to reduce friction, use a drop of oil, which can then be easily removed soap solution.

- When finishing work with the guide, according to the drawing, you should twist all the parts and, for fixation, drop regular nail polish onto the junction of the clamp and the pin.

There are two types of knife sharpening: double-sided and single-sided. The operating principles of these two are, of course, different. All that needs to be taken into account when working with knives are criteria such as:

- The abrasive stone used when working with knives should not have very fine or, conversely, very large grains; choose something in between these two criteria.

- In the case when there is no necessary device for sharpening a knife, and the tool needs to be sharpened, you can use a handy tool such as a ceramic mug. All you need to do is turn the spontaneous sharpening over and move it towards you along its bottom. But it is worth considering that its bottom should have a rough surface.

- Don't forget that ceramic knives do not need sharpening. Their surface is coated with a special coating made of special alloys, which protects it from damage and wear.

- A serrated knife should not be sharpened without special equipment; there is a high probability that you will not sharpen it, but will ruin it. For this kind of knives, a special laser is used.

- To keep knives sharp longer, they should be washed in cold water.

Knife sharpening errors

Features of sharpening planing knives

Only an experienced craftsman with certain skills and knowledge can handle this kind of knives. Since this is a very complex process, sharpening equipment is difficult to find in a regular store. However, many people use conventional equipment to sharpen planer knives. But we must remember that this requires modern instrument low speed, water cooled. You should also use a new stone with a smooth surface; a stone that has a water-based operating principle is better suited. If you are not an expert and you do not have necessary equipment, sharpen planer knife You can do it for a fee at car workshops where you can find such a sharpener.

Video

positroika-doma.ru

Making your own knife sharpening machine

Dull knives in the household can not only cause a bad mood for the housewife, but also cause accidents. Hardware stores have an assortment of tools designed for sharpening knives, but not all of them suit customers. Alternatively, you can make a machine for sharpening knives yourself; the drawings for its manufacture are not difficult for a person who knows how to craft.

Types of stones for processing blades

Before you start making a knife sharpening machine with your own hands, you need to familiarize yourself with information about its components. Sharpening stones, or they may also be called abrasive stones, are one of the decisive factors in achieving excellent results, but no less important role plays the master skill.

Types of whetstones

So to get the perfect sharpening you will have to practice a lot.

There are the following types of stones suitable for sharpening cutting surfaces:

- Tools that require water to operate. The advantage of this type of sharpening stone is that it saves material - the surface of the tool is less susceptible to wear.

- Oil stones are similar in structure to water stones, but have an oily surface.

- Natural stones– made from natural material. Before making a tool, such a stone undergoes industrial processing.

- Artificial stones - used in their manufacture artificial materials. It is believed that instruments made from non-natural components are inferior in quality to natural materials, but they are also quite cheap.

If desired, you can make a homemade abrasive block. To do this, you need to take flat plexiglass 5 mm thick, rectangular in shape, and stick sandpaper on it using double-sided tape. This is the easiest way to make a knife sharpener; it is convenient because when the sandpaper wears out, it is easy to replace.

Why is the sharpening angle so important?

The angle between the edges of the blade is called the sharpening angle. Exact observance of a given angle is the main requirement when processing a cutting surface with an abrasive tool, and it is its value that affects the sharpness of the blade.

Using a simple marker you can control the turning angle; just paint over the area being sharpened with it. Uniform erasing of paint indicates good quality blade processing.

Necessary conditions for a sharpening machine

In order to make a knife sharpening machine with your own hands, you need to carefully plan the stages of work and draw up drawings. If the master has experience, then he can develop them himself or use ready-made drawings that are offered in specialized literature.

For ideal processing of the cutting surface, the machine must meet the following requirements:

- reliable and at the same time not too rigid fixation of the knife in a vice;

- compliance with the angle, during the sharpening process the angle must be constant;

- The design of the machine must provide for the possibility of changing the sharpening angle.

You can read below about how to make your own blade straightening devices that are in no way inferior to purchased mechanisms.

DIY knife sharpener

The most affordable option for a sharpening device

We are making the fastest version of the device. To do this, you need to prepare 2 pairs of wooden corners, an abrasive block and a protractor to correctly determine the sharpening angle. The dimensions of the bars must be the same. The wooden corners are fastened together using adjustable screws, and a sharpening block is securely fixed between them at the required angle.

Despite the ease of manufacture, such machines have a number of disadvantages, these include:

- the processing angle has to be maintained manually - which is not very convenient during a long processing process;

- the need for rigid fixation of the device on the working surface for its stability;

- When sharpening, you need to constantly monitor the tension of the ties so that the block does not change its position.

But it should be noted that such simple homemade products are quite suitable for processing home kitchen knives and do not require large financial investments during manufacture.

Manual sharpener with adjustable stone

This machine is a more complex design, but it is much more convenient to use. The basis for its creation was a model of a machine called the Lansky sharpener.

Lansky sharpener

The advantage of such models is the reliable fixation of the knife blade.

The device is a support table on which the knife is fixed. At the opposite end of the table, a screw stand with a bar is vertically fixed. A guide rod is inserted into this bar, on which an abrasive stone is mounted. By moving the bar along the screw rod, you can change the angle of metal processing.

The advantages of machines with a similar design include:

- high processing accuracy;

- the possibility of replacing the block with sandpaper glued to plexiglass;

- The wide support base allows you to secure the machine with clamps on any table.

When operating the machine, the only difficulty lies in the long-term adjustment of the position of the sharpening stone. If you plan to process different types of blades, you will have to reconfigure the device each time.

Possibility of adjusting the position of the knife

An alternative to a machine with a moving sharpening stone is a device where it is possible to adjust the position of the knife relative to the whetstone. Basically, its design is similar to the machine with an adjustable bar, a little easier to manufacture.

A movable block is mounted on the base plane to secure the rod with the bar. Clamps are also installed on it, one is adjustable, the other is persistent. Using an adjustable clamp, you can adjust the sharpening angle.

The only drawback of this model is the appearance of wear on the bar in one specific place. This drawback can be eliminated by installing a long pin to adjust the edge relative to the surface being processed.

Each option described above has its own advantages and disadvantages. When making your choice in favor of one model or another, you need to focus on the level of skills and the magnitude of the needs for operating the machine.

Video: Making a knife sharpening machine

promzn.ru

Do-it-yourself knife sharpening device - step-by-step instructions with photo examples

Using sharp knives in the kitchen makes cooking much easier, speeds up the process itself, freeing up time for leisure or just relaxing. After all, you need to make a lot of effort to cut meat, slice bread or vegetables with a dull knife.

Modern industry, responding to consumer demand and answering the question: how to sharpen a knife, has developed and introduced into production all kinds of devices for sharpening knives that can satisfy the most demanding customer.

Every housewife has several knives in the kitchen designed for slicing meat, crushing bones or other hard foods. Each knife requires a certain sharpening angle. You can sharpen knives using various devices, which significantly speeds up the sharpening process, but degrades the quality and should be done manually.

It will take special skills and dexterity to sharpen a knife by hand to high-quality sharpness. First you need to choose the right sharpening stone: you will need several whetstones with different grain sizes; a fine grain stone is used to complete the grinding. The surface of the stone must be absolutely flat, without chips, and the length must be no less than the length of the knife blade.

In everyday life, the classic device most often used is a touchstone. By holding the knife at a slight angle and making circular movements, you achieve good sharpening quality. There is an important condition - before doing the work you must wet the whetstone.

Several techniques for sharpening knives

- Wedge-shaped - used for knives used as a lever, quite high-strength and sharp sharpening;

- a blade with a convex or straight bevel is considered more durable and is intended for chopping;

- wedge-shaped sharpening of one side in the form of a chisel is a rather rare form, performed by specialized companies producing knives. This form of sharpening is popular in Japan, the peculiarity is that this form for left-handed and right-handed people requires a different sharpening angle;

- The blade with a curved bevel is ideal for cutting.

It won’t be difficult to make a device for sharpening knives with your own hands.

There are many homemade devices, among which you need to give preference to the one that most satisfies the requirements of a particular consumer. Almost every owner can make knife sharpening devices a high-quality and indispensable assistant in the kitchen.

To do this, you will need a reliable and stable support for fastening and a movable block. The simplest device has the shape of a house; even a child can use it in everyday life. Homemade devices are designed to accurately maintain the angle of inclination to the blade, thus achieving high quality work.

The simplest device for sharpening knives is, in fact, a device consisting of two perpendicularly connected bars, fastened together with pins, between which a sharpening stone is firmly attached at the desired angle.

A type of homemade device is a design with a movable, adjustable platform and a knife firmly attached to it. This mounting design requires a perfectly flat surface.

A marble tabletop is suitable for such a device; you can also put glass on a regular table. A drawing of a device for sharpening knives is easy to prepare even for a person without experience; school knowledge is enough to do this and, based on the drawing, begin creating the required design.

In order for the knives to remain sharp as long as possible, you should adhere to certain rules use and care:

- Under no circumstances should the knife be overheated during sharpening; water can be used to cool the knife during operation;

- in order not to expose the knife to corrosion after sharpening, it must be kept dry; knives cannot be stored together with other cutlery; it is best to use a separate box or special holders;

- monitor the condition of the knife handle; it must hold the blade securely so as not to contribute to injury;

- When working, use wooden and plastic cutting boards, avoiding stone and glass.

If you stick to these simple rules- the knives will last a long time and will bring real pleasure when working with them.

Photos of the best tools for sharpening knives