The well house above the water source performs protective and decorative functions. Let's talk about what types of designs there are, how to make your own from wood and beautifully decorate a well house in the country. We accompanied the article with drawings, photographs and video materials.

Wells provide fresh, cool water, as well as decoration of the site, especially if the headland is decorated with a beautiful house or canopy. When choosing a design, you should start from other structures: a house, a fence, paths, gazebos, etc.

Types of well houses

The house over the well can be of an open or closed design.

When closed, all sides are protected by walls and ceilings that prevent accidental entry of sediment, leaves or other foreign objects into the water. Access to the gate and water is closed by a door, which can be locked if desired. Such structures are sometimes insulated from the inside, especially if winters are harsh and the water level in the well is high.

An open structure is a canopy with open or partially open sides. For safety and to protect water from debris, it is advisable to cover the well mouth with a removable lid.

Design and finishing

Various materials are used to make well houses:

- wood, straw, bamboo;

- metal;

- stones;

- decorative tiles;

- polycarbonate

Often several materials are combined in one structure. If there are facing, building or roofing materials left after the main construction, then their use will not only provide an opportunity to save money, but will also unite the buildings on the site into one ensemble.

Look at the photo for some compatible compositions:

The roof of the house and the canopy are made of the same material

The roof of the house and the canopy are made of the same material

Complete composition with a paved area

Complete composition with a paved area

Rustic option, unpainted wood in all buildings

Rustic option, unpainted wood in all buildings

Imitation of a log house

Imitation of a log house

Tikhvin Mother of God Assumption Monastery

Tikhvin Mother of God Assumption Monastery

A well like this needs a lock in the background

A well like this needs a lock in the background

Unified color scheme and style

Unified color scheme and style

Main material: stone

Most often, the headband is trimmed with stone, and the canopy is made of wood and metal. In this case, the stone can be natural and artificial, as well as imitation stone made of concrete. Sometimes the well tower is made entirely of natural stone, for example, sandstone.

Wooden houses

Well houses made of wood are the most common and fit into most personal plots. For their construction, lumber, logs, driftwood and branches without bark can be used as finishing. Wood is hygroscopic, so it would be correct to treat such materials with some kind of hydrophobic agent and anti-rotting agent.

Well houses made of metal

To decorate the well, you can use forged, openwork structures or sheet metal- galvanized, stainless steel or varnished. Not every owner will get forged products country house, and here closed house It’s quite easy to make one yourself from sheet steel.

Polycarbonate for well houses

Polycarbonate is appropriate to use when garden gazebo, veranda or awning over the car are made using this material. It goes well with metal frame, and can create a certain mood due to its color and relative transparency.

Original well houses

The imagination of designers and craftsmen sometimes it's just amazing. We have prepared for you a selection of the most unusual well houses.

Specific style

If the entire site is designed in a certain, rare style, it may be difficult to choose a well house to match it, because most often you can find ideas for the Russian or pan-European style. We will give some design options that will be appropriate in such specific styles.

"Provence"

"Provence"

"Japan"

"Japan"

"Middle Ages"

"Middle Ages"

"Africa"

"Africa"

"Greece"

"Greece"

“Fairy Tale” (concrete, Anapa)

“Fairy Tale” (concrete, Anapa)

Gate design

Russian mine wells are equipped with a collar with a bucket attached to a chain or rope with a shifted center of gravity (for ease of scooping). The movement of the gate is transmitted by a rotating handle or wheel. The log can also be supplemented with “fingers” - protrusions on its surface that serve as levers for turning. The larger the lever arm, the less effort it will take to pull out a full bucket.

For deep wells, it is advisable to equip the gate with a band brake that controls the speed of lowering the bucket.

Gate with handle (a) and “fingers” (b)

Gate with handle (a) and “fingers” (b)

The gate with a handle is made from thick logs, at least 20 cm in diameter. On one side, a hole is drilled in it exactly in the center along the axis for a blind rod fixed to a support, and on the other - more deep hole under a metal pin connected to a wheel or a curved handle. The ends of the log can be reinforced with metal plates that are attached to opposite rods. The log should be tightly seated on the axle.

Metal parts of gates with handle

Metal parts of gates with handle

Metal parts of a gate with a wheel

Metal parts of a gate with a wheel

Photo with handle assembly

Photo with handle assembly

Making a well house with your own hands

You can make both an open and closed well house with your own hands. Let's look at some easy-to-make designs.

Open house

When building an outdoor house, it is important to remember that the canopy must be wider than the hole in the well and protect it from precipitation, which may not be as clean as in the old days.

Asymmetrical tent over a well

Asymmetrical tent over a well

Symmetrical tent over a well

Symmetrical tent over a well

Let's consider the construction of a canopy over a stone well, representing the supports laid when constructing the head, and truss structure, strengthened on the bases with spacers. How larger area canopy, the larger the cross-section of lumber must be selected during manufacture. The structure is covered with a layer of waterproofing in the form of roofing material and finishing or roofing material to taste.

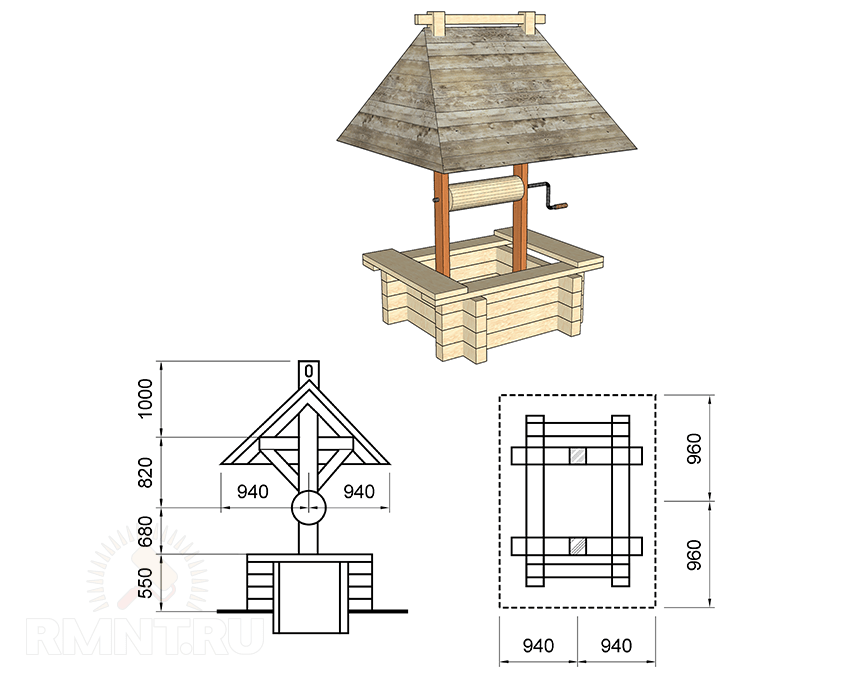

Drawing with dimensions - a tent over a well: 1 - foundation masonry; 2 - rafters; 3 - rafter strapping; 4 — clamp for roofing felt; 5 — struts; 6 - rafter sheathing; 7 - roofing material; 8 - tiles; 9 - ridge; 10 — end stand; 11 - end tie of rafters; 12 - double rafters for bracing; 13 - columnar support

Drawing with dimensions - a tent over a well: 1 - foundation masonry; 2 - rafters; 3 - rafter strapping; 4 — clamp for roofing felt; 5 — struts; 6 - rafter sheathing; 7 - roofing material; 8 - tiles; 9 - ridge; 10 — end stand; 11 - end tie of rafters; 12 - double rafters for bracing; 13 - columnar support

Closed house

Let's make a simple closed house gable design, With minimal finishing. To do this, consider the drawing.

Frame drawing with details

Frame drawing with details

First you need to prepare all the parts, then we begin assembling the frame according to the attached diagram.

Frame assembly: 1 - supports, made symmetrically (see previous drawing); 2 — jumpers (2 pcs.); 3 — strips forming a square platform (8 pcs.); 4 - ridge (pay attention to the cuts)

Frame assembly: 1 - supports, made symmetrically (see previous drawing); 2 — jumpers (2 pcs.); 3 — strips forming a square platform (8 pcs.); 4 - ridge (pay attention to the cuts)

From the ridge to the corners of the site we mount the edges of the future gable roof. Having assembled the frame, we install it on the head.

We sew up the central part, leaving a hatch for access to the water. We mount the assembled gate onto the supports.

We first sew up the end walls with boards, and then the roof slopes, in one of which we mount a rectangular door with a handle on hinges. We protect the edges of the roof with waterproofing material.

We decorate the house with carved overlays. You can cover it with other suitable material.

Ready house

Ready house

Somewhat more complex design and decor during the construction of a fairy-tale well house in the video below.

Part 1

Part 2

A well in the country, and sometimes near the house, is a necessary thing. But just a concrete ring with some kind of cover sticking out of the ground is not very pleasing to the eye, and the comfort of use is below average. To correct the situation, it is necessary to improve it and install a gate that will facilitate the rise of water. Ready-made well fences are sold - with a roof and a gate, but they either have a hefty price or look pitiful. Therefore, most often a house for a well is built with one’s own hands. Then you can use your imagination and arrange everything the way you need.

Types of well houses and their tasks

The primary task of a well house is to protect water from various substances - dust, leaves and other similar contaminants. This requires a tight-fitting lid. Open wells are only possible for technical water - for irrigation. Water from them cannot be used for other purposes. So if you plan to at least wash dishes, the well must be closed tightly.

Protection from precipitation of any kind is also necessary: rain and melt water carry with them very dirty water with fertilizers, animal waste, various garbage and impurities dissolved in it. If it gets into the well, it can cause serious contamination. To protect against precipitation, they make a canopy, most often a gable one - this makes it easier to remove precipitation.

Another purpose of the well house is to protect from strangers or, in any case, to ensure safety for children. To do this, they make latches or cut in locks.

To make it easier to raise water, they install racks and gates - in the simplest case, a rotating log with a handle to which a chain is attached. And all this together should still please the eyes of the owners, but at the same time require minimal care.

Open or closed

As you can see in the photo, the well house can be open or closed. It’s cheaper and easier to make it open: well ring you can decorate it with stone or wood, the lid, racks and canopy can be made of wood or metal - whatever costs less. A minimum of materials is required for this structure. There is only one “but” - in winter the water in such a well can freeze. If you don't plan to use it in cold weather, no problem.

But for winter use An insulated well house is required. But even then it can be made open:

- buy a polystyrene foam “shell” for the well - they are of a suitable size, secure it, and then lay the finishing on top of it;

- The overlap of the ring and the lid should be made of several layers of wood, and the boards should be laid in different directions, overlapping the joints.

Another option is to make an enclosed house. It is slightly larger in size than a well ring. Available air gap It’s already a good heat insulator, but the protection can be further improved by filling the gaps with polystyrene foam, for example.

What to make from

Choosing an appearance sometimes takes a long time. The fair half of humanity especially “suffers” from the desire to decorate a well, going through numerous design options and spending a lot of time doing this. In fact, everything is simple: if you have a house and a well is located nearby, you should decorate it in the same style and, if possible, in the same color. Agree, it looks good.

What to do if the house is brick or plastered? Choose a finish that matches the style. If this is one of the first buildings on the site, just do it as you like.

The question often arises: to make it from metal or wood. Wooden ones certainly look beautiful. But without proper care, they quickly lose all their attractiveness and become gray and ugly. If you are not afraid of the prospect, update regularly, at least once a year. protective covering(delete old paint, then paint it again), make it from wood. If this is not for you, make it from metal. The entire structure or just the frame is your choice. What’s bad about this option: a frame made of galvanized metal profiles, covered with siding. Especially if the house is decorated in exactly the same way.

As you understand, there are a lot of options. First choose the type - open-closed, then materials and finishes to your taste, understand the design, make a house for the well with your own hands.

Canopy for a well with a lid - an open house

Structurally, the device is simple: there are two racks located one opposite the other. They serve as a support for the canopy, and also a gate is attached to them - a device for lifting buckets of water. For a drawing of an open house with dimensions, see the photo below.

Please note that the posts can be dug in after the well ring has been finished. Depending on this, the order of work changes, but the design remains the same in any case.

How to make a canopy

First, the canopy is assembled. Make two side triangles according to the required dimensions. The drawing above shows only the approximate spread of the two extreme points. If necessary, it can be made more. The length of the canopy depends on where the posts will be placed - close to the well ring or behind the casing. The approximate dimensions of the canopy with a ring diameter of 100 cm are shown in the photo below.

Dimensions of a well canopy for a diameter of 100 cm

The structure can be assembled from a galvanized profile, a metal profile pipe or wooden beam. To prevent the profile from bending, it is reinforced at the door fastening points - you can put a wooden block or a metal corner inside.

To ensure that rain does not get inside, the expansion must be done much more more sizes rings - at least 20 cm on each side.

If the racks will be attached directly to the concrete ring, the order of work is slightly different. First, a frame is assembled that covers the ring. In the photo it is made from a 30 mm thick board. The racks are also made of the same board, the place of attachment to the concrete is reinforced with overlays. They also play a decorative role.

If the canopy turns out to be heavy, it is advisable to use timber of greater thickness, otherwise it will not withstand the load.

Afterwards, the previously assembled roof is attached to the racks. You can make triangles right on the spot, but it’s more convenient to prepare them in advance, assemble the rafter system, and then finished form place on racks.

Next is finishing. Sew up with boards, clapboard, roofing material. Just keep in mind that if you use raw boards, they will dry out after some time and gaps up to 5 mm thick will form between them. Then we are not talking about any hygiene: rain and dust will get in... Using a dry board is also not very good - in wet weather it will swell, the flooring will “go in waves.” In general, if you want to have clean water, build a house with doors - closed. There are more chances to protect moisture from contamination.

Do-it-yourself indoor well house

We are talking about this type of shelter for a well - with a door. If you also make a lid inside, dust will definitely not get in.

A frame is built, then it is put on the head of the well and secured with anchor bolts.

- support post made of 100*200 mm

- short support posts made of the same timber 100*200 mm

- fastening beam 30*60 mm

- triangular beam

We assemble the frame and attach it to the ring using short bars. Then we begin assembling the pallet. Assemble the flooring from a board 30*100 mm or so. The frame is sheathed with boards or sheet material, for example waterproof plywood.

To ensure that the doors hold well, you can install additional jibs. We hang doors - one or two, as desired. To make it easier to navigate, below are drawings with dimensions.

Using the same scheme, you can make a roof for a metal house. If you have it, you can use it profile pipe. It is easier to attach finishing material to it.

How to make a completely closed frame

You can also hide a concrete ring in the house. In this case, the gate posts are usually installed separately, and then the frame is assembled. Choose the dimensions so that the design freely covers the ring. The height is 20 centimeters higher than your height: so that you can calmly bend down and get the bucket.

We take the profiles from thick metal, galvanized. From the guide we assemble two identical frames - the “floor” and the upper level of the ring. They are connected by racks (profile for racks). The result is a cube with filled sides.

We cut off the sides of the guide profile, leaving the “back” intact. This way you can make a triangle. We attach a stand that is equal to the height of the entire house. If you want to have equal slopes, the rack is attached in the middle. You can make the far slope steeper, then the stand moves 15-20 cm from the center.

We attach the notched profile to the fixed rack. We get one of the elements rafter system. We perform the same operation on the other side. We connect the resulting tops of the triangles with a crossbar.

On the side of the door we add racks - on both sides. It’s better to strengthen them - put them inside wooden blocks and fasten with self-tapping screws.

Fastening roofing material, for example, a profiled sheet, covered with plywood. The plywood is then laid and nailed soft tiles— who has what technology. The “foot” and sides of the roof are finished with any material. If you want, you can use wood - clapboard, imitation logs or timber, or you can use siding.

In this case, the same materials were used as when cladding the house: so that everything looked like a single ensemble.

Another video example of assembly from a drywall profile in video format.

Making a well ring with your own hands

If a head or canopy is made, the gray concrete ring remains visible. The view is not the most attractive, I just want to decorate it.

Stone finishing

Most popular way decorating the well - finishing with stone - pebbles or small crushed stone. If with finishing material everything is more or less clear - buy or assemble, then the question of what to attach it to remains. There are several recipes:

We offer the third recipe for how to line a well with stone in video format. The composition of the mixture is very similar here, but before applying the solution, a mesh is fixed to the ring. With this technology, nothing will definitely fall off.

An interesting version of a hinged lid for a well is proposed in the following video: it hinges almost completely, but whether such a device is needed is up to you to decide.

Photo options for finishing wells

A well located on its site supplies the house with clean water. drinking water, which is much tastier and healthier than the one received centrally. In order for a well to supply clean water, it must be protected from both rain runoff and bright sunlight, wind-blown debris and various small animals that may fall into it. A well house not only provides protection from these hazards, but also beautifies the well, making it a valuable feature. landscape design and the exterior of the entire site. In this article we will talk about what types of houses for wells are and how to build them yourself.

What types of well houses are there?

Despite the difference architectural styles and shapes, the main division of houses occurs according to the type of well:

- with pump;

- with a collar.

For a well with a pump, it is necessary to create a house that will protect it and provide the possibility of maintenance, but for a pump with a gate this is not enough. After all, the gate must be part of the house, otherwise the effectiveness of the protection provided by the house will decrease, and it will also be very inconvenient to get water from such a well.

The shape of the house can be different, so everyone chooses it based on their preferences and trying to harmoniously fit this structure into the interior of the site. Materials can also be different - from traditional logs to metal corners and plastic. It all depends on your desire, ability to work with various materials and the availability of these same materials. The roof is not a mandatory element of the house, because in villages they still make do with ordinary wooden lids, both completely removable and hinged, however, the roof is perceived much better as a decorative element. A well house with a pump should provide enough free space to service the pump and any type of house should not interfere with preventative cleaning of the well.

How to build a roof for a well yourself

As an example, we will talk about self-construction square house made of sawn timber 10x10 cm, with a lid and a decorative roof made of corrugated board. This house is installed on a well, the walls of which are made of KS 7–9 rings, with a collar, rope and bucket. The outer diameter of these rings is 84 centimeters, the elevation of the last ring above the ground is 40 cm.

To build a well we will need the following materials:

- knob;

- rope or chain;

- sawn timber 100x100 mm;

- board 25 and 50 mm thick and 100–125 mm wide;

- wooden dowels;

- loops;

- foam scrap;

- screws and nails of different sizes;

- insulation (jute, flax, linen or felt);

- cement;

- sand;

- crushed stone;

- fittings

To work you need the following tools:

- chainsaw;

- jigsaw;

- drill with hammer drill mode;

- screwdriver;

- manual rammer;

- wood hacksaw;

- axe;

- chisel;

- hammer;

- shovel;

- roulette;

- pencil;

- square;

- caulk.

Step-by-step construction instructions

First of all, you will need a wrench and a rope or chain. They can be removed from an old house, or you can buy them at any hardware store. The length of the crank must be at least 115 cm; if it is shorter, a longer handle will be required. Having prepared the driver, dig a square hole around the well, 15 cm deep and 180x180 cm in size. Compact the bottom of the hole with a hand tamper and add 5 cm of fine crushed stone or sand. Make formwork with internal dimensions 140x140 and 5–10 cm above the ground, then install it in the hole so that the ring is in the center of the formwork. Make a reinforcing mesh from the reinforcement and install it so that it rises 5 cm above the crushed stone. Mix and pour concrete into the formwork. This operation, as well as the fastening of the frame of the house to the foundation, is described in detail in the articles - Which foundation is better for a house made of timber - calculation features and Fastening timber to different types of foundations.

Here step by step order actions:

- Using a chainsaw, cut the timber into pieces 124–130 cm long. All pieces should be equal in length. Then cut the 50mm board into 4 pieces of the same length. If the board is wider than the beam, then carefully cut off the excess in the center with an ax. These boards are necessary to create a castle that will firmly hold the walls of the house.

- Cut half-wood locks in all sections of timber. To do this, step back 10–15 cm from the edge of the beam (depending on the length of the segments, the main condition is that the distance between the inner edges of the locks should be 84.5–85 cm and be the same on all segments) and draw a line perpendicular to the edges of the beam. Step back 100 mm from this line and draw another parallel line. Lay the beam on its side and, at the level of those lines, draw a line down the center of the beam. Rotate the beam 180 degrees and draw another such line. Then use a hacksaw to cut the timber along perpendicular lines to the longitudinal line and use a chisel to remove the cut piece. If you have never done such work, then first practice on scraps so as not to spoil a good timber.

- Secure to formwork crown molding from two boards and two beams. It is advisable that the beams lie parallel to the wall of the house, so they will look more beautiful.

- Lay two more crowns and secure with wooden dowels. Don’t forget to put insulation between the crowns; this will keep your well from freezing even in the harshest winters.

- Raise the frame of the house so that it rises slightly above the ring, but not more than 1 crown.

- Lay the last crown from boards and timber. Fill the voids between the concrete ring and the frame with polystyrene foam.

- Measure the resulting width of the log house and divide it by the width of the board 50 mm, then round down to the nearest whole number. Cut this number of boards with a thickness of 50 mm, set two aside, and from the rest make two identical panels, fastening them with boards 25 mm thick. These will be the well covers.

- Hang the resulting lids on the remaining two boards and place both doors on the house parallel to the walls of the house. Align them as evenly as possible and attach the outer boards to the frame.

- Cut two pieces of timber of such length that, standing on the foundation, they rise above the frame by 120–140 cm. These will be the roof supports and the gate.

- Drill holes for the knob at a height of 80–90 cm from the top of the frame and insert the knob.

- Attach the supports to the walls of the log house on the sides perpendicular to the canopies using powerful self-tapping screws, screwing them into each crown. Self-tapping screws must be deepened by 30–40 mm, and the holes must be sealed wooden dowels hammering them dry or using PVA glue.

- Measure the bend of the handle of the knob, add 10 cm to it and draw a line at this distance from the knob. This is the mark for installing the roof support beams.

- Determine the most beautiful and pleasant dimensions for the roof. Some make a decorative roof that covers only the lids, others cover it with a roof and a gate, and still others make a huge roof that turns the well into a kind of gazebo. We offer the second option - square gable roof dimensions 180x180 cm.

- Cut 4 pieces of board 50 mm thick and 165–170 cm long and use them to make a roof frame. To do this, use powerful self-tapping screws to screw two boards to the supports. Then attach two perpendicular boards to the ends of these boards using screws or nails.

- If the support rises above the frame by more than 40 cm, then cut the support bars at a height of 40 cm, then cut a groove in the middle of each support for a 25 mm thick board. The grooves should be directed along the axis of the knob. After this, sharpen the tops of the supports at an angle of 45 degrees, this will prevent them from interfering with the roof boards. If the height of the supports is not enough, build them up with boards 50 mm thick, also cut a groove in them and sharpen them.

- Cut a piece of board 25 mm thick equal to the length of the frame plus 5 cm, insert it into the slots of the supports and secure with nails or self-tapping screws. This will be the ridge of the roof.

- Measure the distance from the ridge to the frame and add to it the desired roof overhang (usually from 10 to 30 cm) and add 10 cm to this. Cut 4 pieces of 25 mm board of this thickness and use them to make two corners in the shape of an inverted letter V, which then attach to the ridge and frame. These will be the roof rafters. In this case, each board will need to be attached from above to the ridge flush with its end, and bottom part attach the corner to the edge of the frame with an overlap.

- From a board 25 mm thick, cut 3-4 pieces of sheathing on each side of the roof. The length of the sheathing boards is equal to the length of the ridge.

- Treat all elements of the house with fire protection and impregnate with oil or cover with paint or varnish.

- Nail the sheathing to the rafters, the bottom board along the bottom edge of the sheathing, the top 3-5 cm from the ridge, and the rest at an equal distance between them.

- Sew up the sheathing with corrugated sheeting.

- Cut gable elements from boards 25 mm thick. Mark and cut the corners correctly, thanks to this there will be no gaps between the corrugated sheeting and the pediment. If you mark or cut corners with errors, you will have to install a plinth that will hide the cracks.

- Treat the pediment with fire protection and cover with varnish or paint.

Owners of private houses and summer cottages often strive to create the most comfortable atmosphere in their yard and use a variety of decorative elements for this. Do not bypass and. It is being improved with the help of a house. But the house is not only decorative element. It performs an important function - it protects the contents of the well from penetration various sources pollution. We present to your attention detailed instructions(with drawings and dimensions of parts) on how to create a house with your own hands (photos and video materials are attached).

Since well water is used exclusively for drinking, it should not be contaminated. That is why wells are equipped with special houses that prevent rain and melt water from entering them. These waters may contain debris, various types of waste such as animal feces, bacteria, fertilizers and just plain dirt.

In addition, the house will become an excellent protection from strangers if you close the door of the house with a lock (for example, if the well is located outside your house and you would not want strangers to use it), and will also protect small family members from possible threats .

Wooden well house

Wooden well house In general, well houses can be divided into two types: open and closed. The first option can be classified as a budget option. In this case, it is enough to finish the well ring with stone/wood, but for the canopy and lid, metal or wood is suitable (depending on how much you are willing to “spend generously”). There is only one caveat - in winter, the water in such a well will most likely simply freeze.

If you plan to use drinking water from a well in winter, then care should be taken to insulate the well house.

Advice. When choosing a design for a well house, follow one rule: its appearance must match the style of the residential building and the design of the site.

Some people use wood to cover the roof of their house, while others prefer metal. Let's say right away - if you use wood, then at least once a year you will need to renew its protective coating, otherwise the material will darken and take on a rather unsightly appearance. If you don’t want to fool yourself with caring for wood, then give preference to metal.

Design creation process

Let's consider the most simple model well house, which is quite easy to make with your own hands.

Preparation of tools and materials

Whatever project you choose, it's important to make sure you have everything on hand necessary materials in sufficient quantities, but also the necessary tools:

- hacksaw or jigsaw;

- a woodworking machine (if you don’t have one at hand, a circular saw will do just fine);

- hammer;

- screwdriver;

- level, tape measure;

- edged boards;

- beam;

- slate;

- screws, etc.

Choosing suitable materials, do not forget that the design of the house should not “stand out” from big picture: houses and plots. The type of wood or stone must match the materials used to decorate the house. Can use leftovers building materials or buy ones similar to those used to build the house.

Construction of a house for a well

Construction of a house for a well Construction of frame and roof

Before you start construction work, you need to take all the measurements and make a drawing of the future house, or find photos of finished drawings on the Internet. Remember that even the most simple design must contain the following elements: frame, gables and sheathing, post, ridge, gate and roof slopes.

It is worth noting that many do not use a frame - they place the roof directly on the well ring. But for a more complete and aesthetic look it is better to choose frame structure, especially since it is quite simple to build it. Let's take a step-by-step look at the process of creating a frame base:

- We do everything necessary measurements. Be sure to measure outside diameter well ring.

- Let's start cutting down the boards and beams: we prepare 4 racks 10 cm wide and the same number of boards for strapping (about 14 cm wide).

Advice. You should not use either a massive beam or a board - the structure will be very bulky, or a very thin one - the structure will, on the contrary, be fragile and unreliable.

- After you finish cutting, attach the strapping parts with self-tapping screws to the posts. Please note that the screws must firmly connect all the parts together, so use fasteners at least 10 cm long.

- Making crafts roof trusses(we use durable boards, about 4-5 cm wide and at least 1.6-1.8 m long), we use 8 jibs and 3 crossbars. So, we cut the rafters (possibly at an angle), and at the top we connect them to each other with self-tapping screws.

- We make small cutouts on the rafters at the points of attachment with the top garter and attach them to the frame.

- We install the jibs, thereby strengthening the structure. We connect the finished trusses with a ridge of two boards.

- We lay roofing material on the finished roof and install slate on top. Corner connections cover with wind boards.

Preparation of parts: door and gate

For the gate (spindle) we need a piece of log. Its length should be 4 cm less than the distance between the posts. It is necessary to drill two holes about 5 cm deep in the center of the ends. At the ends of the gate we fix the metal plates with self-tapping screws.

Insert a metal rod about 10 cm long into the left hole at the end (part of it should protrude outwards), and into the right – a bent rod so that it is convenient to grasp with your hands.

We make holes in the racks, insert bushings there and thread the ends of the gate rods. Be sure to lubricate the bushings with grease to prevent squeaking.

Making a door for the house couldn’t be easier: we only need a few boards about 20 cm wide (the length is chosen based on the overall dimensions of the house), from which we will make some kind of shield. We connect the boards to each other with small blocks about 2.5-3 cm wide (two will be enough). To make the door more rigid, we fix an additional block diagonally. All that remains is to attach the handle and latch to the door and put the door on its hinges.

The final stage is processing the entire structure with special protective compounds, which will preserve the appearance of the house and prevent rotting of the wood.

We have discussed in detail the process of creating a well house with your own hands using a minimum amount of materials and tools. We wish you inspiration and high-quality work results. Good luck!

House for a well: video

It costs a lot of money. In this regard, information on how to make a house for a well with your own hands without spending a lot of money will be useful for most people.

House functions

Before you build a well house with your own hands, it is important to understand its purpose. Its main function is to protect the water in the well from contamination and direct sunlight. Insects, debris, dust, sediment, chemicals or excess heat can render the water unusable and roof the house allows you to prevent this. Also proper arrangement the house will protect the water from freezing in winter.

The house protects animals and children from accidents that can occur with open wells. In this sense, such structures can be considered as protective structures.

Another function of the house is decoration. garden. If you design it based on other objects suburban area, you can achieve the creation of a holistic composition. Such harmony of the external environment always contributes to the emergence of internal harmony, which has a beneficial effect on human health.

Design options

There are several design options for a well house. Their shape depends on the original design of the well and the materials used. Based on their shape, all houses can be divided into several types:

- The easiest to build is a roof house, which is represented only by a triangular gable roof.

- More difficult to build are houses in the full sense of the word, which have the appearance of a quadrangular frame and a decorated roof. In the variant when the well is made not from logs, but from concrete rings, the base may have a round shape.

- The original buildings on the site can be houses - gazebos, when the structure is open rather than completely closed. In this version, the roof is supported by two high posts. In this case, the door is formed at the very base, and not in the roof, as in the previous options. The base of such a gazebo can be absolutely different shapes: an ordinary round ring, a log house with a square base, and an octagonal well house look beautiful.

Even typical log cabins can look completely different thanks to different shaped roofs. They can be either gable (symmetrical or asymmetrical), or in the form of a pyramid with different amounts edges or in the form of a cone.

The drawing of the well house, as well as its further construction, will depend on the chosen configuration. The dimensions of the well house should always correspond to the structure of the well itself: a series of concrete rings or a log structure. A roof that is too small will not protect the water in the well from dust, debris and other unnecessary things, but a roof that is too small will large design may make the well inconvenient to use.

- In some cases they use stone to form the base. It can be natural or decorative, and the roof in such houses is usually made of. The buildings take on a medieval appearance and fit particularly well with other similarly designed buildings on the site.

Some well owners prefer to use galvanized steel to create a house. Such buildings are quite simple to carry out, but they are not always pleasing. appearance. It should also be taken into account that a galvanized well house without additional insulation will not be able to protect water from freezing.

Any well is worthy of decoration in the form of carved elements on wooden products, ceramic sculptures on stone buildings or interesting designs on galvanized structures.

Instructions for creating a house

When you decide to build a simple well house with your own hands, step-by-step instruction will look like this:

- Structure frame. They begin to build it after measuring the diameter of the well made of concrete rings - this will become the distance between the sides of the frame. If the well is rectangular or square, the house will be a continuation of the walls. A base frame is made from timber with a cross section of 80*100 mm. If the house is being built from the ground, and not from the upper ring, then it is necessary to make two identical base frames, which are fastened together using 4 timber posts. It is better to use nails at least 100 mm long so that they firmly fasten all the structural parts together. From the center of the upper base frame, two racks of timber are erected, the height of which will become the height of the house. Next, the rafters are installed from the timber, cutting the ends of the beams at an angle of 45° and making cuts in those places where the rafters will connect to the upper base frame. To ensure the strength of the roof, crossbars and jibs are installed. It is imperative to provide a door in the frame, and it can be on the side walls of the roof (if there is no gate in the well) or on the slopes themselves. For the door, you need to install two beams parallel to the rafters and two beams horizontally.

- Base sheathing. If, in addition to the roof itself, the structure of the house contains a base, it is necessary to sheathe it with boards, which is easy to do thanks to the already installed frame. Next, the side triangular surfaces of the roof are sheathed with the same boards.

- Log gate. The gate in the well is necessary to lift the bucket of water. It is made from a log from which the bark is first removed, after which the surface is sanded. The length of the log should be 30-40 mm less than the distance between the posts. This is necessary so that the gate does not cling to the side walls when turning. In the center of the end of the gate (log), holes with a diameter of about 20 mm are drilled on each side. The same holes are drilled in the side walls. To prevent the wooden parts of the structure from coming into contact with the metal bars on which the gate will then be held, it is necessary to install metal plates and bushings. Next, one rod is inserted into the wall on the left side, installing the gate, and one on the right, and on the right side the rod must be bent in a zigzag for ease of use. After this, you can attach a chain with a bucket to the gate.