Building something with your own hands is an activity that not only brings benefits, but also raises self-esteem. Such work cannot be done without concrete solutions. They can take quite a long time to prepare, especially if we're talking about about filling paths or platforms. In some cases, it does not make sense to buy a large concrete mixer for mortar for your needs. But a homemade concrete mixer made from a barrel would be an excellent solution. It will save money and allow you to rationally use the components that are on the farm. What are the methods for manufacturing such a device and assembly diagrams will be discussed in this article.

Why a concrete mixer

When you think about a concrete mixer for mortar, the question may arise as to why complicate your life and not use a drill or mixer. This is a pretty reasonable remark. But it is worth considering for what purposes these tools were originally developed. Drills are used to mix small amounts of low-viscosity solution. If used for a long time, the rotor or stator windings will easily fail. The drill is suitable for drilling holes in metal, wood, plastic and concrete. This is its primary task.

A construction mixer can really help in solving the problem of preparing a solution. Although this tool was developed for these purposes, it is more suitable for working with adhesives and cement-sand mixtures of small and medium volumes. If the task is to prepare concrete filled with crushed stone or other stone, then both the blades themselves and the engine can be damaged. All this speaks to the need for a more powerful product that can easily cope with the stated tasks.

Operating principle

The most common is the rotating concrete mixer for mortar, but in fact, this is not the only type. There are three mixing principles that are used in concrete mixers:

- independent or gravitational;

- exposure to vibration waves;

- mechanical.

The first type of solution mixing is the simplest and is rarely used in industry. It is somewhat reminiscent of throwing mortar with a shovel. But this happens inside the container. The container of the concrete mixer for the solution rotates perpendicular to the ground. Under the influence of gravity, concrete falls from the walls and is mixed. It will not be possible to prepare a large amount of solution in this way, since this is a rather labor-intensive task.

The second method of preparing the solution is the highest quality. It involves the presence of a motor that creates vibration waves in the solution. The container itself, in which the components of the solution are located, does not move. Although such a concrete mixer for mortar provides excellent results, a good amount will be spent on paying for electricity. This happens due to the need for a very powerful motor. Mechanical method mixing is exactly what is used in most available concrete mixers. It combines the gravity method with mixing blades.

What can be used

A homemade concrete mixer for preparing a solution makes it possible to use various components that have long been collecting dust in the attic or backyard. Metal pipes or a corner are suitable for a frame. Large wheels from an old wheelbarrow will also be used in the concrete mixer. It’s easy to assemble a concrete mixer for mortar with your own hands from plastic or metal barrel. The latter can be purchased at a service station, where large volumes of oil are stored in them. According to the drawing, it is also easy to assemble a concrete mixer from an aluminum can that has become leaky or is simply no longer used. Several options will be discussed below. The instructions and drawings provided do not necessarily serve as a step-by-step guide to locating the exact components. They can serve as the basis for your own project.

A homemade concrete mixer for mortar has some advantages compared to a factory one:

- repairability and availability of parts;

- ease of storage;

- comparatively lower cost;

- It’s easy to design what you need according to your needs.

If the design of a concrete mixer for mortar is assembled from improvised means, then you will not have to search for components if something fails. You don’t have to hire specialists to repair a concrete mixer for mortar. You can maintain what you have collected without outside help. You may have to purchase a tiny percentage of spare parts for the concrete mixer, which means that the costs will be low compared to a factory concrete mixer. It is possible to select the parameters of a concrete mixer for mortar for a specific facility.

Concrete mixer without engine

This is the simplest and affordable option, which almost any master can build at home. This concrete mixer for mortar is perfect for those cases when a medium amount of mortar is required, and there is no electricity on site. To assemble such a concrete mixer you will need:

- welding machine;

- inch pipe;

- marking tool;

- metal rod for the axle;

- Bulgarian;

- 40 liter can;

- bearings.

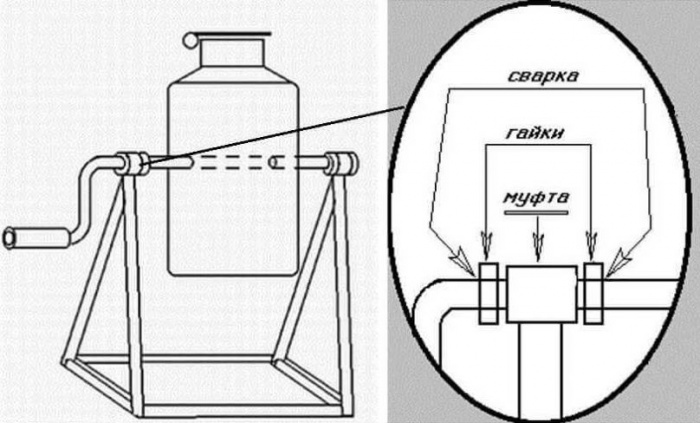

The first step is to build a base or frame for the future concrete mixer. For these purposes, six parts with a length of 1 m are cut using a grinder. Two isosceles triangles are assembled from them using a welding machine. Two metal couplings are welded in the upper corner between the slats. They are selected with a diameter such that 2 bearings can easily be inserted into them. The lower corners of the two triangles are connected by jumpers; additionally, you can install two more jumpers between the triangles. This will result in a monolithic structure that will provide stability to the rotating can.

So that the concrete mixer for the solution does not require titanic efforts when rotating it, it is necessary to balance the can. For these purposes, you can place it sideways on a thin wall and try to find a center of gravity at which it will not tip to one side or the other. This point needs to be noted. Two holes are drilled in the walls. They should be located opposite each other. Their diameter should be 1 mm larger than the diameter of the reinforcement used as an axis. To secure the metal rod in the aluminum can, you can use flanges. They are also assembled independently.

They will require two small pieces of pipe. Its internal diameter should be slightly larger than the diameter of the axis. You also need two small round pieces of sheet metal. The pipe sections are welded to the round pieces in the center. A hole is drilled in the round pieces so that the reinforcement can pass through. Holes with a diameter of 4.8 mm are drilled around the entire perimeter of the circle circle. They are necessary for fixing the flange to the can. The rounds need to be given a slight bend so that they fit snugly into the can.

The process of assembling a concrete mixer is simple. The frame is already ready. The bearings are inserted into place in the couplings. At the end of the reinforcement for the axle, a bend is made for the handle. The flanges are fixed to the can using bolts or metal rivets. The handle is threaded through the first bearing, the can and the second bearing. The can is placed in the middle. The flange pipes are welded to the axial fittings. To prevent the axle from slipping out, stoppers are placed on both sides of the bearings. A schematic drawing of a finished concrete mixer for mortar is shown in the illustration below.

Preparing a solution in this design does not cause any difficulties. It is enough to add all the components for the solution without water and twist them several times. After this, add to the solution required amount water and finish mixing is done. Additionally, such a structure for mixing the solution can be equipped with wheels from an old tricycle to make it easier to transport. The operation of such a concrete mixer can be assessed in the video:

A similar design can be made of concrete mixers for mortar from a barrel. You will have to slightly increase the dimensions of the frame. The rod to hold the barrel must run diagonally. Then sufficient displacement of the solution will be ensured for mixing the components.

To make it easier to visualize what such a concrete mixer for preparing the mixture should look like, below is a diagram. There are no sizes on it, because they are selected individually. All components are clearly marked to aid in assembly. The frame for the concrete mixer is slightly different in the drawing. It is made in the shape of rectangles with an additional jumper. Thanks to this solution, the device for preparing the mixture is more stable.

Driven concrete mixer

The concrete mixer should automate the process of preparing the solution as much as possible. That is why it is worth thinking about how to assemble a structure using an electric drive. It's easy to make a concrete mixer from a 200-liter barrel with your own hands. To work you will need:

- inch frame pipe;

- motor from a washing machine or an old pump;

- 200 liter barrel;

- power button;

- V-belt;

- pulleys from a washing machine, large and small;

- a pair of gears from the starter.

To prevent the solution from falling out of the barrel, its top must be reduced in diameter. To do this, an incision 20 cm deep is made every 15 cm in the shape of a small triangle. After this, all the blades are bent towards the middle and boiled.

The large gear from the starter is placed on the bottom and the necessary markings are made so that later it can be secured.

A frame is assembled from a pipe or angle that will hold the barrel. You can make it according to the sample shown in the photo below. Two pieces of pipe are simply bent at an angle of 90 degrees and reinforced with a small piece of sheet metal. An axle for the wheels is mounted on the lower part. A pulley is welded onto the crossbar that will hold the barrel, onto which a large gear will subsequently be attached.

The next step is to install a pipe with bearings, into which a second pulley with a smaller gear is installed. The distance must be calculated so that the concrete mixer gears easily interact with each other. Wheels can be used from an old car or even from a Lada. But then you will additionally need hubs, which can be found at disassembly.

The motor from the washing machine is mounted at the bottom of the frame under the gears. The electrical connection is also made. A regular 6 amp starter can be used as a switch.

Lastly, the barrel is mounted in its place, which completes the entire structure. To prevent the pulley from bending under the weight during the preparation of the mixture, it is necessary to make two safety wheels that can support the barrel from the front. The illustration shows how they can be fixed.

There is another way to make a concrete mixer from a 200 liter barrel. In the design of such a unit for preparing the mixture, the unit through which rotation is transmitted from the engine to the container will be different. To assemble this option for preparing the solution, you will need an unnecessary car disk. The entire internal part is cut out so that only two external ones with sides remain. A hub is attached to them, which ties them together. After this, the resulting unit is attached to the concrete mixer barrel through rubber gaskets.

Rotation will be transmitted from the motor to the smaller pulley through the belt. A wheel with a smaller diameter is attached to a smaller pulley and from it, through a belt, rotation occurs to the fixed disk.

This is what the structure looks like from the back. You can see how the main components are secured to the concrete mixer. The motor and pulleys must be adjusted so that the belts move straight without distortion, as they will simply fly off.

You can use a regular automatic machine as a starter for a concrete mixer, but it’s more interesting to use a block from an old washing machine. It has a timer. Once you launch it, you can safely work on others preparatory work. Once the concrete mixer has stopped, the solution can be used. It is important to remember that the solution cannot be left for a long period of time, because the water from it may evaporate or the solution itself will shrink and lose its viscosity.

Note! Excellent concrete mixers are made from barrels that are made of stainless steel. They are more durable and neutral to the components of the solution. True, the weight of such a concrete mixer will be slightly higher.

In the drawing for assembling a concrete mixer for mortar, try to provide for the possibility of changing the angle of the barrel. To do this, the base on which the tank will rest will need to be fixed on two bearings and made movable. Another option would be to implement a stop at the front of the concrete mixer. With such a mechanism, it will be much easier to pour the solution out of the concrete mixer and it will be easy to do this directly at the place where the solution is used. A video of the operation of a concrete mixer, which was made from a barrel with your own hands, can be seen below:

Advice! You can make a concrete mixer for mortar with your own hands not only from metal, but also from plastic barrel. To do this, you will need to select a barrel with thick walls, and also strengthen the upper part with a metal plate, which will be secured with a ring. The amount of solution that can be prepared at once is comparatively less than in a metal concrete mixer, but the efficiency is not inferior.

Conclusion

As you can see, if you show a little ingenuity and look at what you have in your bins, you can assemble your own concrete mixer with virtually no expense. A properly assembled concrete mixer will not be inferior to a factory one in performance. In addition, it will not need to be sent for warranty repairs, and you can fix everything yourself.

A concrete mixer is an indispensable device for performing various construction work. The time when mortar for construction was mixed by hand is long gone. Today, in every industry, people are trying to simplify and automate manual labor as much as possible.

Likewise, in construction, to make work easier, they came up with a device that would help prepare homogeneous concrete mixtures. The mixing process in these mechanisms is carried out by mechanically mixing together all the ingredients of the solution. Usually it is cement, water and sand.

For large construction projects, an industrial machine is the only choice. And in a small construction site (for example, in a private house), the best choice is a concrete mixer, made with your own hands, taking into account all the requirements.

What is she like?

In most cases, this design is a drum in which the mixing process directly takes place. It receives rotational energy using a mechanical drive and an electric motor. The electric motor in this case is the heart of the machine. These builder's assistants differ in power, drum volume, and type of execution.

But not all devices have such a standard design. There is a forced type device. It looks a little different. Here the container for the solution is made without the possibility of movement. It has specially shaped blades. Due to their movement, all components are mixed. This system does not allow mixing of particularly large particles. The machine is intended only for liquid mixtures. But a self-made concrete mixer made according to this principle can mix even large fractions of the solution.

How to make a high quality solution?

In preparing correct and high-quality mortar There are several basic principles. Each of them must be observed, otherwise there is a risk that the solution will be spoiled and will not have the required qualities.

So, what are the requirements for the process of mixing the ingredients of the solution? Firstly, the cooking time should not exceed 3 minutes. If the process takes longer, it will cause a centrifugation effect, which will significantly deteriorate the quality of the solution.

Secondly, when the mixing process is completed, the neck of the concrete mixer container should be lowered to unload the mixture. There is no need to turn it off.

How to make a homemade concrete mixer with your own hands?

If you need to build a house or utility room in a country house or country estate, then first of all you need to acquire such a device. Making the solution with your own hands is inconvenient, time-consuming and difficult.

The need for this useful machine This is especially true in the private sector. Because sometimes there is a need small construction, something always needs to be reconstructed or rebuilt. Even to fill a garden path or make a foundation for a gazebo in the garden, you need a solution.

A self-made concrete mixer is good way save money, since the unit is rarely needed, and the price for factory and industrial models is quite high. And there is no point in buying it for a couple of times. Besides, do something with my own hands- it's exciting and interesting.

Choosing a container

To build our machine, we first need to select a container. In this case, the required volume must be taken into account. You can find an old metal or plastic barrel on the site; a 200-liter barrel is enough.

Base

This structure is quite large in size, so you need to provide a sufficiently sized base for it. The manufacture of this element must be approached thoroughly.

Wood is used to create the base. A timber with a cross-section of 10-15 cm is suitable. We will connect the frame with a tenon joint. First you need to process all the joints using glue and screws. Such a homemade concrete mixer, made with your own hands, will be able to withstand loads.

A base made of metal, of course, is more reliable. But if the device will not be used frequently, this is not practical. And this will only make the structure weigh more. A channel or corner is suitable as materials for a metal frame. It can be assembled using welding and bolted connections.

On the base, it should be possible to mount the drive, as well as a tilting system and a counterweight with which the solution will be unloaded. You also need to remember about the controls.

Motor selection

A self-made concrete mixer, in our case, will be powered by an electric motor. Any single-phase motor is perfect for this. The rotation speed should be no more than 40 revolutions.

There are people who successfully use motors from old washing machines for these purposes. The design of these motors allows them to work for a very long time, and there is no risk of overheating, overload or anything else. These units have good torque, so you need to provide a gearbox system. To do this, you can use a belt drive with pulleys of various diameters.

How to make a concrete mixer from a barrel with your own hands?

Since the design is based on a regular barrel, any 200-liter metal barrel will do. It is imperative to clean the barrel well after work. If the container is not cleaned, sooner or later pieces of dried solution will form inside. This will make it difficult to unload the finished solution from the barrel. This way the device will not last long.

Manual drive

How to make a manual concrete mixer with your own hands? In order for the solution to mix, it is necessary that our barrel can rotate freely around its axis.

To make loading and unloading more convenient, you need to install a door in the barrel. To do this, you need to make a cutout on the side of the container. The door can be secured using hinges. You also need to provide a retainer and seal.

To organize a manual drive, you can make holes in the center of the barrel on both sides for a small diameter pipe. It will act as an engine. How to fix the pipe? You can use welding, you can use flanges and bolted connections.

To improve the quality of mixing the ingredients, metal strips can be welded to the walls from the inside of the barrel. This will create the blades that are found in the design of industrial mixers.

bed

A self-made concrete mixer made from a barrel will have a lot of weight when loaded. The frame for it must be strong enough and stable. In addition, the barrel must spin.

The material can be used wood or metal. Anything will do: profile, corners, timber. This design provides 2 tripods on both sides. The tripods are fastened together longitudinally. The height of these supports should be such that it is convenient to work with the machine. It is necessary to take into account that such a structure will move around the site. To make it easier to work with it, you can press suitable bearings into the flanges.

Forced stirrer

We learned how to make a concrete mixer with our own hands. Now we will see how to assemble a forced-type mixer. Making a device is not as difficult as it seems.

Such a device has some design features. Here the whole barrel does not rotate, but a shaft with blades rotates inside it. There are designs with a horizontal or vertical shaft.

A forced concrete mixer, constructed with your own hands, may be slightly inferior to industrial products, but it will cost much less.

First we need a barrel. For a horizontal structure, a special trough may be needed. You need to make a hole in the end of the barrel. Then a shaft is inserted into it, onto which a bearing is pressed. The bottom of the barrel must have a door for unloading the solution.

The shaft can be made either from pipes or fittings. The blades can be welded to the shaft. They are easily made from sheet metal.

Many do-it-yourself concrete mixers, the drawings of which are easy to find if desired, are equipped with motors with a power of 2.2 kW or more as an electric motor. And to ensure that the shaft speed does not exceed 48, gearboxes are used. You can use a belt drive, or a chain drive from an old mountain bike.

Can you imagine a construction site that doesn't even have a small concrete mixer? Without such a unit, preparing a good cement mortar becomes almost impossible. When the need arises to build a small structure or simply “patch up” something, concreting becomes a popular task. That's just short list situations in which it is impossible to do without of this instrument: fill garden paths, arranging a foundation for a gazebo, installing a fence, and so on. In a word, concrete is needed everywhere - the only difference is the scale of the event. For household needs There is no point in buying an industrial device - the purchase will cost you prohibitively. An alternative solution would be a homemade concrete mixer with your own hands. Thanks to this article, you will learn how to make it yourself from scrap materials.

Four Principles of Mixing Concrete

Homemade concrete mixer

Homemade concrete mixer According to the facts, you can prepare your own solution without special devices. Many people even like to work “according to the old method.” But how much do you manage to do this way? It is still possible to create a dry mixture for construction using a conventional drill or mixer. But when it comes to sand and cement, they are powerless.

The simplest and most common mixing principle is called forced. All components are mixed in a container that is stationary. A mechanical drive is usually used for this. The working drum can be positioned vertically or horizontally.

Drawing of a horizontal concrete mixer

Drawing of a horizontal concrete mixer Despite the fact that even a small forced-action concrete mixer can be very effective, it also has its disadvantages:

- “Dead zones” appear in the container. This especially applies to the space near the walls.

- Complexity of design. Rotation units must be hermetically protected from the effects of the solution, which may be aggressive.

- It is almost impossible to prepare a solution in such a unit, which includes medium and large filler.

The second principle is called gravitational. In this case, all components are mixed due to gravity. In industry this method It is rarely used because it requires a lot of time and effort. Barrels made of metal are most often used as containers. How they are made and how to make a stand will be discussed below.

Most modern concrete mixers use a combined principle that combines the first two methods. They have the following advantages:

- Strict sealing is not necessary. The drum is open at the top; there is no need for rotation units, since any contact with the solution is excluded.

- Parts wear out much less often.

- Simplicity and reliability of operation.

- There are also no restrictions on the composition of the solution - it can be crushed stone, expanded clay, gravel, and so on.

The fourth principle of mixing is called vibrational. Recently, some craftsmen have been mixing the solution using vibration. If we talk about large-scale volumes, the results can be the most stunning. Typically, the vibration mixing principle is used when it is necessary to produce a precise reinforced concrete structure with good performance characteristics.

Under normal conditions, the gearbox and drive are replaced by a powerful hammer drill (permissible minimum 1.3 kW). Its vibration action must be independent. There is no need to press the cartridge.

Concrete mixer gearbox photo

Concrete mixer gearbox photo In general, vibration mixing allows you to create an almost perfect concrete mixture. However, it is also not optimal for preparing a “heavy” solution.

Concrete mixer from a milk can (flask)

DIY concrete mixer from a milk can

DIY concrete mixer from a milk can It is worth understanding that not everyone has access to electricity. summer cottage. Therefore, it would be quite logical to make a homemade product of a manual type and of small volume. A DIY concrete mixer made from a milk flask is a very simple and uncomplicated option. You will need the can itself, pipe scraps or any other scrap metal of a similar shape. It can be done in 2-3 hours; the main scope of work involves welding the frame.

- Taking round pipe, bend the handle as shown in the picture. Weld the water couplings at the top. Their internal diameter must exceed the diameter of the pipe used for the handle.

- Pass the tube through the flask, making holes, and then weld it to the body.

- It is extremely important to find the center of gravity of the concrete mixer with your own hands so that it can be turned easily. To simplify the design, you can do without using a coupling. Cut arc-shaped recesses in the frame and place the axle on them.

The unit, although simple, is not the most reliable. Therefore, for manufacturing it is better to use some other drawings.

Big barrel

Concrete mixer from a large barrel 200 liters

Concrete mixer from a large barrel 200 liters More practical option A concrete mixer made from a 200 liter barrel is considered. Why exactly two hundred liters? This volume is considered optimal for mixing concrete at a time. The plastic option is immediately discarded - such barrels will not last you long.

A homemade concrete mixer from a barrel is made as follows:

- Preparing a barrel that has a lid and a bottom. If the cover is missing, it is welded separately. Didn't find the container? You can do it yourself. Homemade option is in no way inferior to a factory barrel. You will need dense sheets of metal with a thickness of 1.5 to 2 mm, rollers, an effective welding machine and a wooden hammer.

- We attach flanges with bearings to the lid and bottom. We cut out a hatch on the side where the solution components will be filled. A little trick - for a concrete mixer made from a barrel, such a hole should be made closer to the end, which will be lower during the scrolling process.

- Knowing how to make a concrete mixer with your own hands is half the battle. It is equally important to ensure proper mixing of the solution. To do this, you need to weld the blades to the inside walls (angle from 30 to 40 degrees). This angle is extremely important so that during the mixing process the contents are “pushed” out. In principle, you can attach the blades to the shaft.

How do professionals make a base for a concrete mixer?

Naturally, a manual concrete mixer with your own hands must have a stable base. This is necessary so that the structure does not start to turn over during mixing. With a small load of the frame from wooden beam will be quite sufficient (section 10 by 10 or 15 by 15 cm). Optimal connection options: “tenon” or “half-tree”. They are necessary so that the structure does not suffer damage from vibration. When the assembly is completed, all joints are glued and tightened with self-tapping screws.

Need a stronger, more durable unit? Then a frame made from a metal corner will definitely suit you. Welding machine Not everyone has it, but you can fix it with rivets or bolts.

If necessary, wheels are screwed to the base. This arrangement of the concrete mixer will allow you not only to turn it over, but also to move it.

As for engines, a DIY concrete mixer from a barrel can be equipped with a motor from a scooter or car. A good option There will also be a concrete mixer from a washing machine. The advantage of this option is that it is designed for long-term operation and can last for several years.

How to make a concrete mixer with your own hands video

Below you can see photos of drawings that allow you to do everything yourself:

Drawing of a homemade concrete mixer from a barrel

Drawing of a homemade concrete mixer from a barrel At what speed should I mix concrete?

We will not consider in detail the process of mixing concrete - this is the topic of a separate article. Let us only note the fact that the torsional moment plays an important role.

This is why the washer gearbox is better than a regular motor from a scooter or car. It can withstand almost any load and can operate at low speeds. 25 full cycles (revolutions) per minute is enough.

To provide this quantity, the gearbox can have a different design. The simplest, most typical option is when the gearbox is made of a belt and pulley. A do-it-yourself concrete mixer with a moped motor is distinguished by its mobility. The gearbox is convenient and compact; it does not require electricity to operate. Even if you have a large area, the made device moves around it without unnecessary worries and hassle.

The gearbox in this case must be chain, otherwise the design will not function well.

Absolutely anyone can save a substantial amount of money if they know how to make a concrete mixer with their own hands - photos and videos are attached to the instructions. You will need the minimum building materials, tools, a little attentiveness and resourcefulness. And one last piece of advice in conclusion. If there is such an opportunity, it is advisable to involve one more (or preferably two) people in the work. Some steps need to be completed at once, and doing it alone is not very convenient.

Homemade concrete mixer from a barrel video

It is difficult to even imagine any construction without technological processes using cement mortars. And for the owners of their own country house, with their constant state of “permanent” repairs and landscaping, concreting in general is a very popular operation - either garden paths need to be poured, then a foundation for a gazebo, then a blind area needs to be renovated, or a fence needs to be put up... In a word, literally on every each step requires the production of concrete - the only difference is the scale of the event.

Many individual builders prefer not to bother with mixing the mortar themselves - this can be avoided if there is a reinforced concrete plant or other enterprise nearby that provides services for the production of concrete and its delivery to the work site. But, firstly, it costs a lot of money. Secondly, this opportunity is not available everywhere. And thirdly, it does not always make sense to resort to such services for reasons of the small scale of the construction or repair task - it will either be simply ridiculous or extremely unprofitable. It’s easier to make the required amount of solution yourself. This, of course, can be done manually, but it is better to purchase (rent) a concrete mixer or show yourself as a real owner: for the future, make yourself a concrete mixer with your own hands.

The article will discuss several homemade models concrete mixers - from the simplest to those that are not much different from the samples presented in stores.

A short excursion - what types of concrete mixers are there?

By and large, you can cook without any equipment at all. Some craftsmen even like to work “the old fashioned way”, mixing nt with sand and other components (if necessary), and then gradually adding the required amount of water. For this purpose, large containers with low sides, factory-made or even home-made, knocked together from boards and lined with thin metal, are used.

Mixing by hand - how much time do you have to do this?Some people prefer to do without containers altogether, simply preparing the solution on a prepared, level area. However, in any case, the procedure of mixing first dry components with a shovel or hoe, and then with water, is a very labor-intensive process that takes a lot of effort at the preliminary stage, before concreting begins. And if the work is planned to be quite large-scale, then this approach will not justify itself.

Prices for concrete mixers Vikhr

concrete mixer Whirlwind

Construction mixers or drill attachments - these are more suitable for dry construction mixtures or composite polymer materials. Sand and cement for them is already a rather difficult “test”, and if there is still a need to add gravel, crushed stone or expanded clay of a large fraction, then the mixer or drill can be safely put aside: not only will you not achieve a high-quality, homogeneous mixture, but also and there is a high risk of overheating the gearbox or electric drive of the device.

Concrete mixers (concrete mixers) cope with this task, which differ not only in size, capacity and drive power, but also in the principle of their operation.

Forced mixing principle

Forced principle - the components of the solution are mixed in a stationary container. It is carried out due to the circular movements of the shaft with blades connected to a mechanical drive. (Work with construction mixer or a drill with an attachment can also be safely attributed to the forced kneading principle).

The installation layout may vary. Thus, the working drum can be a vertically located cylinder of small height, in which the paddle blades rotate on a vertical axis (as in the figure above).

Another option is when the container itself is located horizontally, and the shaft with blades is also oriented in a horizontal plane. Below is circuit diagram such a concrete mixer - who knows, perhaps it will serve as a prototype for someone to make on their own.

In the drawing the numbers indicate:

1 – drum body, in which the solution is mixed.

2 – a frame on which all components of the unit are mounted.

3 – Electric drive. In this case, with such dimensions of the mixer, the optimal power would be about 5 ÷ 6 kW.

4 – monitoring and control elements: power switches, indicator lamps.

5 – Bottom hatch (gate) – for unloading the finished solution into a container placed below.

6 – lever for opening the shutter.

7 – safety grid installed during kneading.

8 – gearbox for transmitting rotation from the electric drive to the working shaft.

9 – belt drive protective cover.

10 – safety clutch.

11 – a working shaft with blades installed on it for mixing the solution.

Unloading of the finished solution can be organized according to a different principle - the working drum is mounted on the frame not rigidly, but hingedly. When mixing concrete, it is locked in the working position. And in order to remove the finished solution, a container removed from the stopper, and with the help of a special lever it rotates in the suspension axles. The solution is unloaded into the substituted container through the upper loading hatch.

Another scheme is somewhat simpler, with a lever for tipping the containerForced action concrete mixers make it possible to achieve very high levels of solution homogeneity. They are actively used in industrial conditions, in construction, and in private practice. However, they are not without quite significant drawbacks:

- In a working container, it is often impossible to avoid the creation of “dead zones” - along the walls, especially in the corners. It is not easy to fit the blades with a minimum gap to the inner walls of the cylinder, especially since under such conditions there is a constant increase in wear of the rubbing parts.

- Structural complexity - reliable sealed protection of rotating units (bearing blocks) on the working shaft from the aggressive effects of cement mortar is required.

- It is almost impossible to prepare a solution with medium or coarse filler in such a concrete mixer. But for plastering and finishing work, using ready-made building mixtures, this is the most optimal option.

Gravity mixing

The gravitational principle of mixing - the components of the solution are mixed under the influence of their own gravity. A good example: place two different products in a glass jar, for example, two types of cereal, close the lid and start rotating - mixing will begin.

It is clear that this approach in its “pure” form does not provide high-quality preparation of the solution, or will require too much time to achieve an acceptable consistency. In industrial conditions, this method is not used, but for home needs a small, simple concrete mixer can be made.

The drawing shows a can - it is convenient from the point of view of tightly closing the lid. But, in principle, almost any container can be used if the owner carefully considers the issue of securely closing it while mixing the solution.

The axis of rotation can be fixed outside the container - in this case, it is not necessary to ensure the sealing of the assembly as it passes through the wall. But it’s still better to make it through - such an artificial obstacle during gravitational mixing of the solution will somewhat improve its quality.

On the Internet you can find many interesting solutions for making such simple concrete mixers from improvised materials. Very often old iron barrels are used. Making a stand is something that probably no good home craftsman will encounter any particular difficulties with.

The most difficult thing, probably, is, again, to think through the issue of a tight-fitting hatch, which open state will allow loading of the mixture components and pouring water, and when closed, while stirring, will prevent the liquid solution from leaking out. The approaches here may be different, but most often they use a door with welded hinges, the opening for which is sealed with rubber around the perimeter.

Some creative craftsmen complicate the design somewhat in order to improve the quality of concrete mixing. So, for example, to increase the amplitude of differences in height, the barrel can be positioned not along the “correct” axis of the cylinder, but diagonally.

Rotating such a concrete mixer, of course, is somewhat more difficult, but uniform mixing of the solution will be achieved faster.

Combined principle

So, it was mentioned above that the gravitational principle of mixing in its “pure form” is not distinguished by productivity and high quality of the batch. You will probably hear objections - after all, it is believed, and many sources claim, that most conventional concrete mixers with a rotating drum located at an angle use precisely the gravitational principle. We can agree with this, but only by making one very important remark.

In such mixing devices, the blades are necessarily rigidly fixed on the inner surface of the working drum. Their configuration and size are thought out by the designers. When rotating, these blades move relative to the solution tending downward under its weight. Thus, in this case it would be more appropriate to talk about the combination of two principles - both gravitational and forced. And indeed, this is exactly how the vast majority of cooking devices are designed.

There are several advantages:

- No sealing is required, neither the drum itself (it is constantly open at the top), nor the rotation unit (since no contact with the solution is assumed here).

- Part wear is significantly less.

- Such concrete mixers are simple and reliable in operation, easy to maintain.

- There are practically no restrictions on the component composition of the solution - crushed stone, gravel, expanded clay, etc. can be used.

The manufacture of a concrete mixer of this type will be discussed in more detail.

By the way, let’s return for a minute to those simple concrete mixers-barrels mentioned above. If you show a little ingenuity, it is also very easy to modernize them, dramatically improving both their performance and the quality of the mixed solution. To do this, it is enough to triple the blades or any other artificial obstacles on their inner surface.

One of the options is shown in the diagram. In this case, a comb is used, which is easy to weld from a corner and a piece of reinforcing rod. Two such combs will immediately transfer the concrete mixer from the category of gravitational ones to the “family” of more advanced, combined ones.

Vibration mixing of solution components

Not so often, but still some enthusiasts try to apply the principle of mixing concrete mortar using vibration. In industrial conditions, such installations give excellent results and are used for the production of highly precise reinforced concrete parts with the highest performance characteristics.

And at home, craftsmen try to use a powerful one as a drive (the main thing is that its vibration action is independent and does not require pressing the cartridge against an obstacle).

It turns out something like this:

1 – body of the container in which the components of the solution are mixed. Preference is given to round, not too large in radius, but high tubs (barrels).

2 – a bracket is rigidly attached to the body, which houses a vibration pulse generator, in our case a hammer drill (item 3).

The power of the hammer drill must be at least 1.3 - 1.5 kW. Even this will not guarantee success, and with less drive force, it is not worth trying.

A long rod (pos. 4) is inserted into the hammer drill chuck, which is connected to a vibrator (pos. 6). This rod must be of such length that the disc vibrator is located in height approximately in the center of the layer of the prepared solution (item 5).

It seems that everything is simple, but such a scheme does not always show good results. Mistakes most often lie in neglecting seemingly small nuances:

- A flat vibrator simply won’t work. A shape is needed that will propagate vibrations in a dense medium from a central point almost spherically to the periphery. There should be something spindle-shaped, similar to two plates connected together with the bottoms facing out. In principle, this is one of the solutions - two metal plates mounted on an axis.

- The diameter of the vibrator depends on the drive power. When making calculations, you can proceed from their approximate proportions: 150 ÷ 200 mm per 1 kW of hammer drill power. So, if we take a 1.5 kW hammer drill, then we prepare “plates” from 225 to 300 mm in diameter.

- The diameter of the cylinder itself should be such that from the outer edge of the vibrator, placed exactly in the center, to the wall of the container there is a distance approximately equal to the radius of the plate.

- To create vibration waves that can handle stirring cement-sand mixture, the level of the solution above and below the vibrator must be approximately equal to the diameter of the “plates”.

Vibration mixing concrete mixtures gives excellent quality solution. The process is very easily monitored visually - from active stirring, movement, bubbling - to a smooth, rippling surface (ready solution). But, you must admit that for this you need to comply with a lot of specific “whims”. And one more thing - “heavy” solutions with gravel or crushed stone are also problematic to prepare in this way. So this method is not widely used among private owners - it is easier to make a concrete mixer according to the “classical” scheme.

Self-production of a “classic” concrete mixer

It is necessary to immediately warn the “hot heads” - not everyone can take on the production of such a concrete mixer. Although in many articles there is a “bravura motive” that it is both easier and cheaper than buying a ready-made one, you still shouldn’t believe it.

- Firstly, you should not start such work if the owner knows about the art of welding only by hearsay or is involved in this field.

“Secondly, the work will be profitable if most of the components for making a concrete mixer can be found among unnecessary things in your own household, from neighbors, or even in a landfill.

- Thirdly, the existing experience in design, production of plumbing, welding, electrical work and available inexpensive or even free materials must be multiplied by the expressed desire to make a concrete mixer yourself. There is a fairly large category of people who can’t wait to try to do everything with their own hands - this is a task specifically for them. If you start work without fulfilling such conditions, simply cherishing the ephemeral hope of saving something, then it’s better not to start. Time and materials will be wasted, and it will be much cheaper and easier to purchase a small and inexpensive concrete mixer - fortunately, the choice is quite large.

General scheme concrete mixers - approximately the sameIf we consider almost any of these concrete mixers, then three main structural units always clearly stand out:

- The container itself (tub) in which the solution is mixed, with all the additional mixing devices located in it.

- Frame (frame, frame), which serves to place on it a mixing tub, an electric or manual drive, controls and, if necessary, means of movement. The frame must provide a movable hinged fastening of the container, a degree of its freedom both around its own axis and relative to the horizon with different angles of inclination. The structure itself can be stationary, or it can have wheels for moving around the construction site.

- Drive is a mechanism that ensures rotation of the mixer container around its axis. In most cases it is used electric drive. For small concrete mixers, a manual drive may be sufficient. You can (rarely) come across options for installing internal combustion engines (gasoline or diesel) - then the concrete mixer will not be dependent on the power source. Any drive transmits torque with the number of revolutions required for the mixing technology through a gearbox (there are no restrictions - craftsmen use any type of transmission - gear, belt, worm, etc.).

Now let's look at the manufacture of all these units separately.

Mixing tub

When making a mixing container, it is assumed that during operation it is usually filled to a maximum of 30–40% of its total volume. Typically, these buckets are made with a volume of 100 to 200 liters. If you exceed these limits, it will be difficult to independently create a reliable, stable frame and equip a homemade concrete mixer with such a powerful drive. With small tank volumes, both assembly and operation of a concrete mixer often become simply unprofitable.

Prices for concrete mixers Enkor

concrete mixer Enkor

The easiest way, of course, is to find a ready-made container that is suitable in volume and dimensions as the main mixer. It immediately suggests itself se the same metal barrel.

The simplest approach is again a metal barrelThis option is entirely possible, but for a good concrete mixer, the cylindrical shape of the tub is not optimal. A lot of unmixed solution may remain in the corners around the bottom, and it is possible that the solution will splash out from above when stirring.

Making a smooth transition from wall to wall is a very difficult task, but probably any craftsman can give the barrel a pear-shaped shape. Triangular cuts are made on top, and then the remaining “petals” are welded so that a uniform narrowing is obtained.

Improved barrel - the upper part is narrowedAn interesting solution was found by a craftsman who decided to use a plastic barrel. Why not? Smooth curves of the shape are what is required for a concrete mixer container. It is quite possible to attach the blades to its inner surface, and from the outside below - an axis with a rotation transmission mechanism, not by welding, but screw connections. But what a huge gain in terms of the weight of the device itself!

Original approach- plastic barrelAs a result, the designer of this model even made do not with a steel frame, but with a mobile wooden base - a wheeled trolley.

The height of a standard barrel for use as a concrete mixer container is still too large and complicates the alignment of the entire unit. Please note that in such cases, support rollers are usually used for stabilization - the high tub seems to roll along them, resting on its upper part.

If there is no suitable container, but available sheet metal, thickness 2 ÷ 3 mm, then you can try your hand at making a container yourself, giving it all the necessary shapes.

Not to be unfounded, for those owners who consider themselves masters in welding work, we can offer an interesting drawing for the manufacture of a “classic” concrete mixer with a drop-shaped tub.

The overall dimensions of the container, without the connection unit with the gearbox, are 400 ÷ 500 mm. It would seem - not much, compact, but even only in the cylindrical part about 30 liters of solution fit - a completely acceptable indicator for a household concrete mixer.

1 – automobile wheel hub. You can make this part yourself, but it’s still easier to use a ready-made one.

2 - bottom of the tub. Cut from a steel sheet, preferably 5 mm thick. The figure below shows this position separately in an enlarged view. Holes (8 PC, with a diameter of 6.5 mm) must exactly coincide with the holes on the hub (pos. 1 ).

3 – the cylindrical part of the tub (shell) is welded from a steel strip bent into a ring, 2 mm thick, dimensions 150 × 1580 mm. All welds when assembling the tub are made continuous and sealed. It is advisable to strengthen the shell from above with a metal band ( tape).

4 — the conical part of the tub is welded from four identical parts. Their dimensions, including the radii of curvature in the upper and lower parts, are shown in the figure.

5 – along the top edge, the edge of the tub is flared outward, and By a steel rod with a diameter of 10 mm is welded around the circle (well shown in the diagram - node A ).

6 – “blades” - solution dividers - are welded inside the tub. In this case, the structure shown in the diagram, made of reinforcing rod with a diameter of 16 mm, will be quite sufficient. 3 pairs of such dividers are made and welded evenly around the circumference, every 120°. By the way, they should also give the tub additional strength. Each pair has one straight divider running from the bottom in the neck, and one curved at a right angle.

Bottom node ( B), which includes the already mentioned hub and bottom, is better shown in a separate, enlarged drawing.

7 – bolts connecting the hub to the bottom. The nuts are located on the outside. Between the parts there is a rubber gasket of at least 2 ÷ 3 mm (item 11).

8 – a screw with a washer that secures the hub to the output shaft of the gearbox (pos. 9 ). The hub is protected from turning on the shaft by a key (pos. 10 ).

Lower connection block ( B) is prepared, tried on, but mounted only after assembling the frame and installing the drive and gearbox on it. In principle, this will be one of the final operations - on a unit already mounted to the gearbox B the concrete mixing tank will be “seated” on the screws.

All welds must be descaled and carefully inspected to ensure complete leak-proof tubs.

Video: homemade concrete mixer with a tub welded from a steel sheet

Concrete mixer frame

In the manufacture of frames or trolleys for concrete mixers, the ingenuity of craftsmen who can adapt unnecessary metal parts and wheels for this design is also quite welcome.

The frames can have wheels, which means they can be easily transported to Right place. You can also make a stationary, motionless frame - it is easier to manufacture, and in conditions suburban area Usually, any larger movements of the concrete mixer are not planned.

Frames may also differ in the degree of freedom provided to the mixing tub. Thus, the container can be installed hingedly, changing the angle of inclination of its axis to the horizon as necessary - for solutions of varying degrees of “heaviness”, for dumping ready-made concrete, for washing the container, etc.

A simpler option is when the tub on the frame always occupies one position, and to unload the solution the entire concrete mixer tilts forward - like a wheelbarrow (as shown in one of the pictures above) or children's rocking chairs on arched runners.

Video: homemade concrete mixer with a swing-type frame

However, let's continue to consider the drawing of a concrete mixer, the manufacture of which was described above. It is quite possible to go along this path. The drawing, for ease of perception and for greater clarity in the size and arrangement of parts, is presented in two projections.

Concrete mixer - front viewAssembling such a frame from ordinary and profile pipes and scraps of sheet metal will not be at all something extremely difficult for an experienced mechanic or welder. Meanwhile, this design has been well tested - it is not heavy, but it ensures reliable stability of the concrete mixer in the transport and working position, and ensures maximum ease of operation.

She is a side view1 - this is the same tub that was described in the previous section of the article.

2 – a lever handle for installing the tub in the desired position and for tipping it over when unloading. For a lever you can use steel pipe½ inch (½ʺ).

3 – a gusset cut from 3 mm steel (s 3) ensures reliable fastening of the lever to the rotating subframe (pos. 18 ).

4 – metal wheels Ø 350 mm. They are usually taken from decommissioned agricultural machinery.

5 – thrust legs with thrust bearings for stable installation of the concrete mixer in the working position. They are made of ½ʺ pipe (the stands themselves) and s3 steel (thrust bearings).

6 – cross beam of the concrete mixer frame. A profile pipe with a cross section of 60 × 20 mm is used.

8 - an inclined beam (pipe 60 × 20 mm), and for its rigidity - a strut (pos. 7 ) Related to cross beam. For the strut - ½ʺ pipe.

9 – a panel to which the electric drive controls will be attached. The panel is cut from s3 steel.

11 – wheel axle. Made from a metal circle Ø16 mm - according to the size of the mounting hole available wheels

12 – longitudinal beam concrete mixer bed. Profile pipe 60 × 20 mm.

13 – vertical stand. Profile pipe 60 × 20 mm.

14 – eye of the hinged fastening of the rotary subframe. Two parts are made from s5 steel.

15 – transmission gearbox. In this version - a ready-made assembly, worm type, with a gear ratio i = 17.

16 – safety clutch on the electric drive shaft.

17 – . Specifically, in this concrete mixer model, the developer used a three-phase drive (380 V), with a rated power of 1 kW, and a rotation speed of 950 rpm.

18 – a swinging subframe on which both the electric drive with the gearbox and the mixing tub itself are mounted. It is made from the following parts: two spars from a ¾ʺ pipe, four cross members from a 35 × 35 mm angle.

19 , 20 And 21 – electric drive control elements: start button, capacitor box and power cord with a three-phase socket, respectively.

Now - a slightly larger knot A, which ensures installation and fixation of the mixing tub in the desired position.

On a stretcher (pos. 18 ) the eye is welded (pos. 22 ), and on the inclined stand (pos. 8 ) – sector (pos. 10 ). Both the eye and the sector can be made of s3 steel. The selected position is fixed with a pin (pos. 23 ), and so that it does not get lost, it is recommended to hang it on a chain.

The number of fixed positions in a sector may vary. However, it is usually enough T reh:

– at an angle of 50° to the horizontal – for mixing heavy concrete solutions;

– at an angle of 30 ° - for preparing light mortars (for example, masonry);

– horizontally – for washing the tub.

After assembling the frame, all welds are removed from slag, the parts must be cleaned of corrosion. Then it is recommended to cover the structure with high-quality metal paint. The rubbing components of the frame (subframe suspension in the frame lugs, wheel axles) are generously coated with conventional hinge grease.

In the variant under consideration, the drive and gearbox unit are attached to the subframe (so that precise alignment is maintained). After checking the functionality (test run), you can finally assemble the concrete mixer by placing the mixing tub in place and securing it with bolts.

A few words about the drive

In the example under consideration, the electric motor and gearbox already recommended by the model developer were used. However, in the practice of self-manufacturing concrete mixers, it is very common There is a situation when a master “on the fly” selects a drive from what is available and comes up with a way to transmit torque to the mixing tank.

It is customary to calculate the required electric drive power based on the ratio of 20 W per liter of solution in a scheme with an inclined tub. (When positioned horizontally, for example, in models with a barrel on a horizontal axis, 15 W/l will be sufficient). You should not forget about this ratio so as not to overload the drive. For example, if the engine in our case has a power of 1 kW, then you should not mix more than 50 liters of solution, regardless of the size of the tub itself.

Thus, often the tub itself begins to be manufactured, starting from the parameters of the drive that is planned to be installed on the concrete mixer.

The rotation speed of the mixer bucket should also be within certain framework . So, it is considered optimal from 30 to 50 rpm. To make the speed lower is to deliberately delay the process of making the solution. And if the speed is too high, the solution will begin to splash.

Finding a ready-made gearbox that would meet the requirements both in terms of dimensions and gear ratio is not always possible. Therefore, many masters find their own, sometimes very original ways transmission of torque ensuring the required angular velocity. In the version that was considered, the mixer is mounted directly on the driven axis of the gearbox. However, often the tub is installed on a free axle, and the torque laneeats on it by gear, belt, chain transmission. For example, here are a few original solutions:

Instead of pulleys - bicycle wheelsHomemade gearbox - drive from an old washing machine, it transmits rotation through belt drives through the pulleys of their gears and old bicycle wheels.

The simplest frame with a homemade gearboxFixed frame for a concrete mixer with a homemade gearbox.

Homemade gearbox, which combines a belt and two chain transmission. Again, there were some bicycle parts.

A small-sized concrete mixer, the rotation of which is transmitted directly to the bucket through a belt drive. The pulley is structurally located on the mixing tank itself.

Car parts that are no longer needed in the garage are often used. A popular solution is to use a flywheel with a ring gear. By the way, it is very easy to find a pair of drive gears - from the Bendix starter of the car, since they are “made for each other”.

The flywheel can be completely welded to the bottom of the tub.

Another option is when only the ring gear is used. There is probably no need to say that in this case, very careful centering will be an extremely important point.

In a word, a thrifty owner can very often find parts for his own original solution to the issue of manufacturing the required gearbox. Perhaps the options shown will be a good hint for someone.

Video: another design option for a concrete mixer

Prices for concrete mixers Stroymash

concrete mixer Stroymash

If everything worked out, then the owner can be congratulated on successfully finding a good “helper”. But in order for the concrete mixer to last longer and not cause any emergency incidents, you need to adhere to certain rules:

- Like any equipment associated with the consumption of electricity, a concrete mixer requires compliance with electrical safety rules. And in this case, this issue is even more acute, since operation is always carried out in conditions high humidity and a high probability of water splashing. That is, all cables and contact connections must have the most reliable insulation, completely eliminating electric shock or short circuit.

- The operation of a concrete mixer is always associated with high levels of vibration. This leads to loosening of threaded connections, which means they need to be checked and tightened regularly. At the same time, one should not forget to monitor the safety of other components and parts, welds, etc.

- Before starting work, you need to make sure that the concrete mixer is installed securely. It should rest tightly on all of its standard stands. If the structure is mobile, then wheel chocks (wedges) are placed under the wheels.

- Never, under any circumstances Not Do not leave a running concrete mixer unattended. Curious people, and especially children, should not be allowed near her.

- When working, it is better to use skin and eye protection, since cement has a rather aggressive effect on tissues and mucous membranes.

- Checking the quality of the resulting solution with a shovel or stick while the concrete mixer is running is the height of imprudence! Very often such actions end in serious injury to the hands or face.

And in conclusion of the article - proof that the limits of creativity when creating homemade equipment- No.

Video: homemade concrete mixer based on an old T-16 tractor

As a rule, construction work is rarely completed without the use of concrete. It is quite difficult to mix the solution with your own hands, using only a large container and a shovel, and, given the significant scale of the upcoming work, it is completely impractical. It is much more convenient to mix concrete using a concrete mixer. Such a unit can be purchased at any specialized store, but still many, in an effort to save money, try to make it themselves. Do-it-yourself concrete mixer is a great opportunity get one like this useful device at minimal financial costs. How it can be made will be discussed in today’s article.

Popular DIY concrete mixer designs

Let's look at a few simple options which are the most popular.

Option #1. Mechanical

You can see the design of this simple mechanical mixing unit in the image below. The main advantage of such a concrete mixer is that it has an impressive volume. As for the drive, in this case it can be either manual or electric. To unload concrete, the bucket must be tilted to one side.

But there is also a disadvantage inherent, in principle, to all units with a cylindrical tub - this is poor-quality mixing in the corners. The mixture also sprays if the speed is more than 35 revolutions per minute. But the second problem can be dealt with if, after completing assembly, you weld that part of the barrel that was cut back into place and make a hatch in it.

Note! This DIY concrete mixer mixes a simple solution in no more than 5 minutes, and a dry solution in 1-12 minutes.

Video - Manual concrete mixer with a cylindrical bucket

Option #2. Horizontal combined design, which is equipped with combs

This design, as well as the one described above, can also be either manual or electric. The advantages include high mixing homogeneity, as well as high speed and the quality of the procedure. A similar concrete mixer is made from old barrel, but its quality is not much inferior to the best modern models for industrial use. What is characteristic is that the mixing speed is determined by the number of revolutions, and not by time (to prepare the solution, you need to turn it only three to four times).

Although there is a minus - it is that the design is quite complex. To make even a manual version you will need several dozen different elements. Wherein Special attention should be given specifically to the unloading hatch - all seals, latches with hinges must be of exceptional quality and reliable. However, if you have a lot of work to do in record time a short time in a place where there is no electrical power, then such a concrete mixer will be very useful. Finally, we note that similar structures are also manufactured on an industrial scale.

Option #3. Electrical design

This is perhaps the most common option, which in most cases is copied by home craftsmen. Therefore, there is no need to particularly explain anything. You can find the diagram in the image below. There are many varieties that have one or another design differences, and finding detailed drawings is not difficult. In a word, we will give only some explanations.

- The neck and bottom of the container must be reinforced with strips welded crosswise.

- Most suitable in this case is a frame mixer, which is welded to the axle.

- It is recommended that the container rotates along with the axis - this will make the frame design more complicated, but you will not have to seal the shaft in the bottom (the latter is precisely one of the reasons for the short service life of the mixers).

Video - The process of assembling a concrete mixer

Option number 4. Vibration unit

Quite often, people, having a hammer drill with a power of 1-1.3 kilowatts with a percussion mechanism that is forcibly turned on, tried to make a vibrating concrete mixer on their own, but in most cases they did not get the desired result.

Let's take a look at common mistakes.

- First of all, this is the wrong selection of container. The latter should only be round, not too wide, but high.

- The vibrator is not positioned correctly. It should be positioned on the axis of the container, and the distance from it to the bottom should approximately correspond to its radius. There should be a solution above the vibrator itself with a height that does not exceed its (again) diameter.

- A flat vibrator is used. The fact is that if it is made of a sheet of metal, it will not be able to excite the required system of waves in the concrete. It is important that the profile of the element is at least approximately the same as shown in the image. The best option– a pair of saucers or plates (preferably metal ones), which are folded together.

- And the last thing is that the vibrator is too big size. Its diameter should be 15-20 centimeters for each kilowatt of power. Simply put, if the power of the hammer drill is the same 1.3 kilowatts, then the device will cope with plates with a diameter of 25 centimeters. If the diameter is large, then a concrete mixer simply will not be able to “pump” the solution with its own hands.

If you follow all these requirements, you can get concrete of excellent quality.

Video - Making an original concrete mixer

Making a concrete mixer - step by step guide

To make the design described below, you will need, first of all, patience, since you will have to work hard. The process consists of several successive stages; let’s look at the features of each of them.

Stage one. Capacity

To make a mixing bowl (also known as a mixing bowl), prepare a ready-made tub or the materials you'll use to make it. There are a lot possible options– a drum from a washing machine, an old can, a barrel. Although if you put forward special requirements for the future design, then it is preferable to make the pear yourself. Prepare sheet metal (can be new) with a thickness of 2 to 2.5 millimeters. Then get to work.

Make 3 or 4 components of the future container. A pair of truncated cones (this will be the bottom and top), the base (in other words, the most Bottom part), and also fastening the cones in the center (if this is necessary at all).

After this, weld all the elements together to obtain a pear (it, according to preliminary calculations, has a volume of about 200 liters). In addition, it is desirable that there is a double weld at each attachment point. It is worth noting that craftsmen often advise attaching metal rivets between a pair of welds to increase reliability, although this point is not necessary.

Stage two. Body and base

As for the body, it is often made of wood, but if you are serious about durability, then it is better to use a metal corner. Give preference to durable material that has a minimum of rust (if scrap metal is used), and also take care of designing the most convenient base. The future body must withstand the planned weight with a margin of 20-50 percent, since during vibration and mixing, the load will accordingly only increase. Moreover, take into account that in addition to the concrete itself weighing 100-200 kilograms, you also need to hold the container itself, with the necessary additional accessories.

All fastenings are carried out by welding and auxiliary bolted connections. At the same time, it is recommended to take care of the practicality of the future unit. The concrete mixer can be placed on a frame with wheels for more convenient transportation of the “miracle of technology.” You can also take care of a convenient handle, with the help of which the body will move around the construction site.

Stage three. Engine

This stage is rightfully considered the most difficult, since it is quite difficult to calculate what characteristics and parameters the future equipment should have. Therefore, the power must be determined based on the requirements for the volume and weight of the concrete being mixed, as well as the ability to extract a particular engine. Some use a motor from a washing machine or a scooter for these purposes, while others prefer less expensive equipment (for example, a motor from an electric drill or any similar tool).

We also note that both the power and the speed at which the concrete mixer will rotate with your own hands must be taken into account. It is important that it is not very high - say, about 15-20 revolutions per minute. There are several ways to adjust the speed - automatic, gears with shafts, homemade device, and also the use of belts.

Stage four. Direct assembly of the concrete mixer

The assembly procedure itself is not complicated and includes several successive steps. Let's look at each of them in more detail.

Step one. First you need to make sure that all connections - both pears and housings - are strong enough. Fasteners should be provided in advance, the same applies to the connection location and installation of the motor.

Step two. After this, you need to install the engine and gearbox on the frame, and then carefully fix all the parts of the rotating mechanism.

Step three. The next stage is installing the container on the axis and base. This should be done so that the pear is located at an angle of 35 degrees.

Step four. Now all that remains is to check how the concrete mixer turns on/off, whether the fastenings are secure, and how well the rotation occurs. Gears or a belt are used to adjust all parameters.

Note! The procedure described above is more clearly demonstrated in the thematic video below. After watching it, you will finally understand how to make and launch the device described in this article.

Video - Homemade concrete mixer

It is worth noting that any of the designs described above can be a good alternative to expensive “store-bought” equipment. Although, of course, in the absence of the required consumables, the cost of such budget equipment may increase significantly; although the experience is in any case very interesting. In addition, the design of a concrete mixer can be made cheaper, and the principle of its operation can be simplified. This can be done, for example, by replacing automatic rotation with manual rotation. In this case, instead of dozens of complex parts, you will only need bearings, a handle, a lever, and also a “comb”, which will be located inside the pear.

Another option for making a concrete mixer

The design presented below is very similar to that described in the previous section, and therefore no detailed explanation is required here. The manufacturing procedure itself can be understood from the step-by-step illustrations provided. Let us only note that in this example, a ready-made 200-liter barrel, a 250-watt electric motor with 1430 rpm, a motorcycle wheel, and a pair of rings welded together are used. The finished pulley will be welded to the bottom of the tank. You will also need a pair of belts, a channel and pipes 59 for the frame.

Feasibility of the solution

So we found out that cement mortar required for almost all construction work. And if, for example, to fill the foundation, it is advisable to use a purchased ready mixture, then in the case of work involving the periodic use of relatively small portions of the mixture, it is advisable to rent/buy a concrete mixer (can be manual, but preferably electric).

Of course, you can use the same trough with a shovel for kneading, but this approach, in addition to being labor intensive, has other disadvantages. In this case, the quality of concrete will not be high; the mixture will turn out to be heterogeneous, which, in turn, will lead to unnecessary expense dry cement and low strength characteristics of ready-made concrete.

Note! The term "concrete mixer" means whole line special construction mixers (manual/electric), that is, devices designed to obtain a homogeneous cement-containing mixture by mixing ingredients with dissimilar fractions.

As a rule, dry cement is mixed with water, special additives and fillers (the latter can be sand, expanded clay, screenings, crushed stone).

How does a concrete mixer work?

Standard design includes:

- bed (it can be either on a chassis or stationary);

- kneading working bodies;

- the container in which the mixing process takes place;

- unloading mechanism;

- transmission;

- driving unit (it can be, for example, gasoline or electric).

Let's take a closer look at each of the structural components.

- So, the frame is a structure made of profiles/pipes and is intended to connect all parts of the concrete mixer into one system. If the unit is small, then the frame can be equipped with two/four wheels to make it easier to transport.

- Mixing organs often include blades, augers and other parts that directly act on the ingredients of the concrete being mixed.

- The container is the element in which all these ingredients are mixed. Its volume and dimensions depend mainly on the productivity of the concrete mixer.

- Unloading mechanism - as the name suggests, it is intended for removing concrete for further use in construction work. It can also be different.

- Finally, a transmission with a driving unit is needed to convert this or that energy into the movement of the kneading organ. As noted earlier, the engine can be electric (used most often) or gasoline.

Main types of concrete mixers

There are several classifications of the unit described in the article, according to which it is divided according to one or another parameter. Thus, according to the principle of their operation, concrete mixers come in five varieties.

- Gravitational. They differ in that the drum for mixing the solution rotates under the influence of gravity. The best option for preparing viscous and rigid concrete.

- Forced. A more difficult to make concrete mixer with your own hands, where the container does not move, and the blades inside it mix the components of the mixture. Such units are rarely used in private construction.

- Periodic. They are characterized by low power and therefore require frequent stops. But for private construction this is a completely acceptable option.

- Geared (better known as crown-type).

- Permanent. Such concrete mixers, as their name suggests, operate continuously, and therefore are used primarily for large volumes of work.

In addition, depending on the type of concrete being produced, equipment can be of two types

- mortar mixers;

- concrete mixers.

Let's look at each of these options in more detail.

Option #1. Mortar mixers

Simple equipment designed for private construction. Designed for mixing components whose fraction size is more than 2 centimeters. Also, units can be industrial (if the volume does not exceed 1200 liters) and for private use (over 30 liters).

As a rule, all ingredients are mixed in mortar mixers forcibly, for which a horizontal auger is used, which rotates in a fixed container. If the volume of the unit is more than 100 liters, then it must be equipped with dispensers. And if the volume of equipment exceeds 250 liters, then, as a rule, it will include the following elements:

- engine;

- mixing container;

- drive unit;

- a rotating shaft having blades.

Note! Small mortar mixers with a volume not exceeding 65 liters are emptied by tilting the drum. If the volume is larger, then a hatch is used for this, which is located at the bottom of the device.

Option #2. Concrete mixers

They are designed for use with components whose fraction size is no more than 7 centimeters. All units of this type are classified in the same way as described in one of the previous sections of the article.

In addition, depending on the installation features, they can be: